How We Support You in Picking the Perfect Upender and Tilter?

When it comes to choosing the right upender and tilter for your business, the process involves more than just selecting a machine; it’s about finding a solution that aligns with your production goals, operational challenges, and long-term vision. With so many options on the market, the decision can feel overwhelming. But the right choice can transform your workflow, improve safety, and unlock efficiencies you didn’t think possible.

Our goal is to make this decision easier for you. With years of expertise and a proven track record, we provide tailored solutions that meet your specific needs. From understanding the unique aspects of your operations to offering robust after-sales support, we ensure that your investment delivers both immediate and lasting value.

By the end of this guide, you’ll have a clear understanding of how we help you choose the perfect upender and tilter—one that’s not only designed for today’s demands but also future-proofed for tomorrow’s growth.

1. Which aspects of our Upender and Tilter are tailored to suit your production goals?

1.1 Customization options that align with your unique objectives

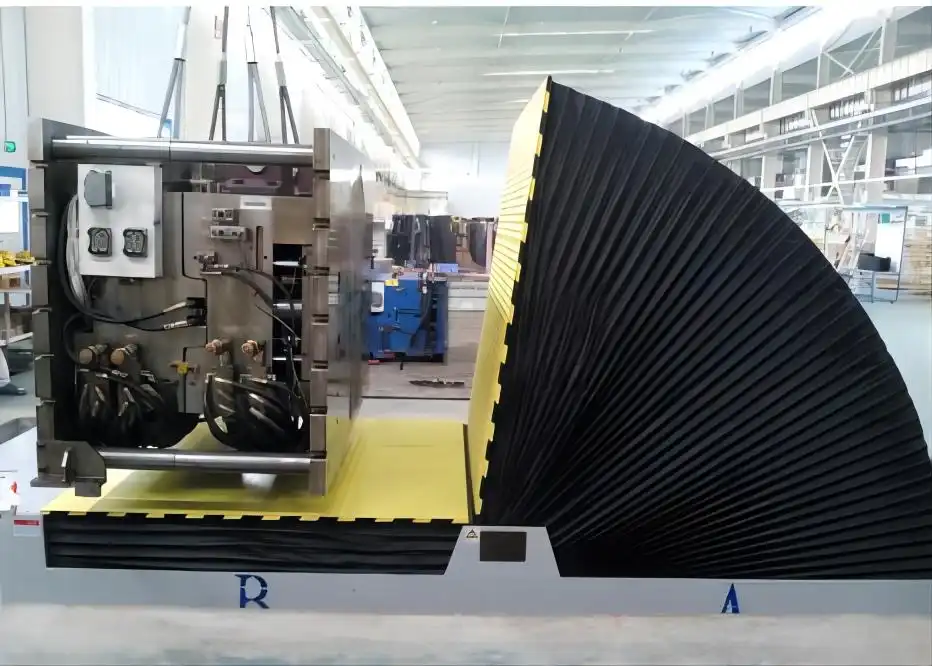

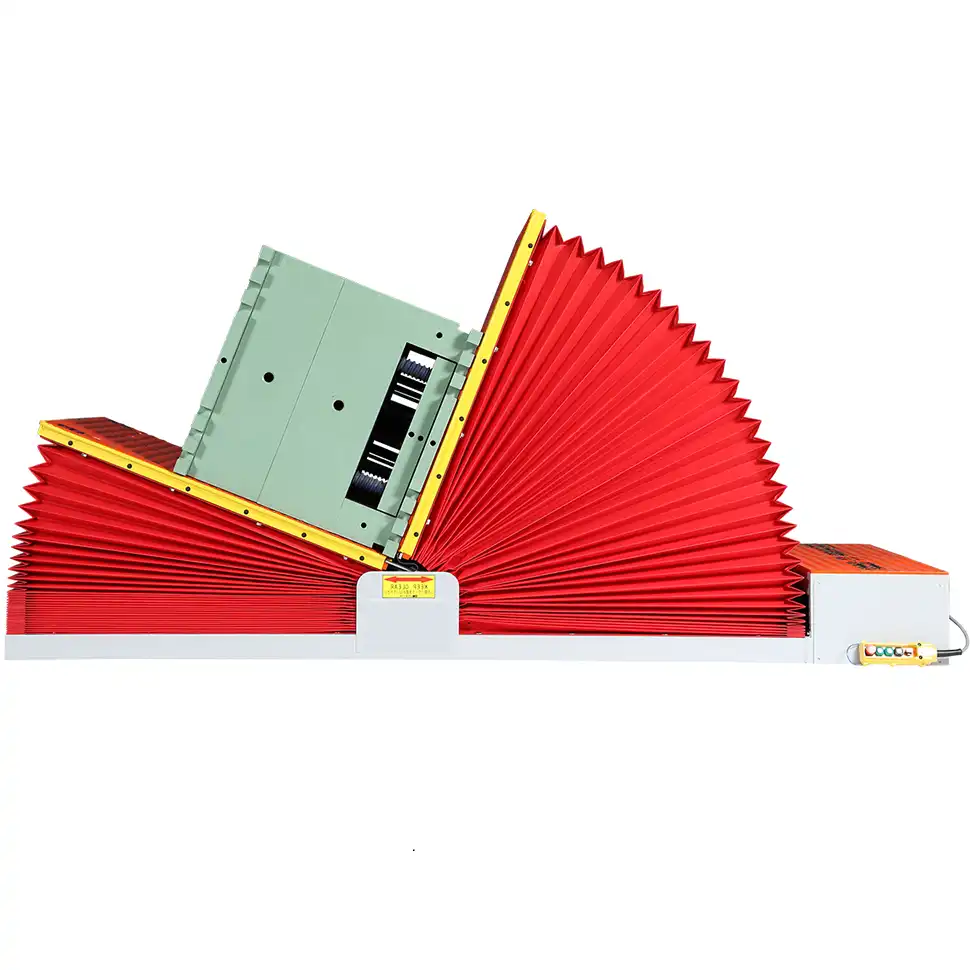

Every business is different, and no two operations are the same. That’s why we prioritize customization when it comes to our upenders and tilters. Whether your production goals involve handling delicate materials, managing heavy loads, or improving overall efficiency, we design solutions that align with your specific needs.

Our equipment is built with adjustable configurations, load capacities ranging from lightweight to heavy-duty, and optional features like automated controls and IoT integration. These options allow the machines to adapt seamlessly to your workflow, ensuring that efficiency and safety are never compromised.

Additionally, our team takes the time to understand your production goals. By analyzing your current processes, pain points, and growth plans, we recommend solutions that aren’t just a good fit—they’re the perfect fit.

1.2 How our tailored designs meet industry-specific needs

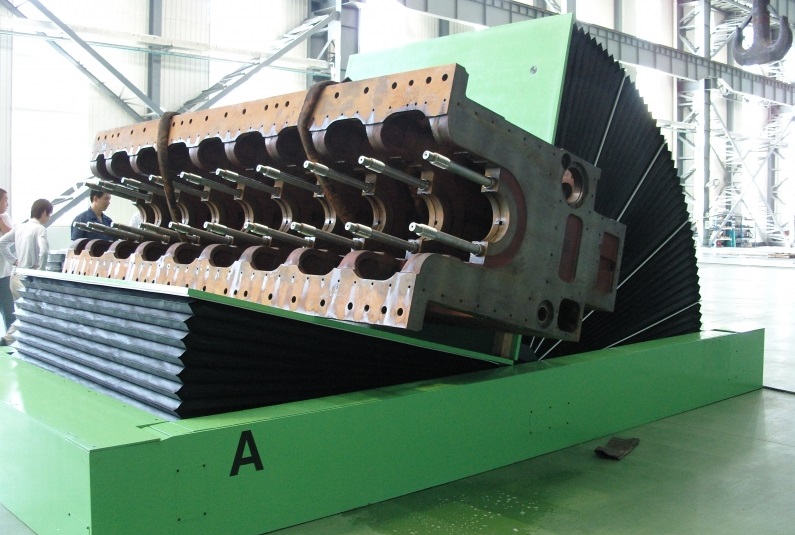

Each industry comes with its own set of challenges. Whether you’re in manufacturing, automotive, or logistics, our upenders and tilters are designed to meet the specific demands of your industry.

| Industry | Key Needs | Our Solution |

|---|---|---|

| Automotive | Handling heavy, irregularly shaped parts | Heavy-duty tilters with precise rotation controls. |

| Food & Beverage | Hygiene and contamination prevention | Stainless steel designs for easy cleaning. |

| Pharmaceuticals | Safe handling of fragile materials | Adjustable clamps and precision tilting mechanisms. |

| Logistics & Warehousing | Speed and efficiency in pallet handling | High-speed automated systems with IoT compatibility. |

For instance, in the automotive sector, irregularly shaped parts often create handling challenges. Our heavy-duty tilters are not only designed to manage these loads but also ensure precise rotations, minimizing the risk of damage. Meanwhile, in the food and beverage industry, our hygienic designs ensure compliance with safety standards while improving operational efficiency.

1.3 Advanced technologies that enhance operational efficiency

Our upenders and tilters aren’t just machines—they’re tools designed to enhance productivity. By incorporating advanced technologies like IoT-enabled monitoring and automation, we ensure that your equipment delivers more than just functionality.

| Feature | How It Works | Benefit |

|---|---|---|

| IoT Integration | Real-time tracking of load conditions. | Improves efficiency and provides actionable insights. |

| Automated Control Systems | Reduces manual intervention in operations. | Speeds up processes while reducing human error. |

| Precision Tilting Mechanisms | Ensures smooth rotation of fragile items. | Minimizes product damage and increases reliability. |

These features not only improve day-to-day operations but also provide long-term value by reducing downtime and increasing throughput.

1.4 How our solutions reduce downtime and improve efficiency

One of the biggest challenges businesses face is minimizing downtime while maximizing productivity. Our upenders and tilters are designed to address this issue head-on, offering features that streamline operations and enhance reliability.

| Metric | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Average Setup Time | 30 minutes | 10 minutes | 67% faster |

| Downtime Per Month | 15 hours | 2 hours | 87% reduction |

| Throughput | 500 units/day | 800 units/day | 60% increase |

By reducing setup times and preventing breakdowns, our equipment ensures that your operations remain smooth and uninterrupted.

1.5 Two fact statements about tailored designs

True: Customized upenders and tilters can improve operational efficiency by up to 50%.

Tailored solutions align perfectly with your workflow, eliminating bottlenecks and improving overall performance.

False: Standardized upenders and tilters are always more cost-effective than customized ones.

While standardized machines may have lower upfront costs, they often fail to address specific operational needs, leading to inefficiencies and higher long-term expenses.

2. What makes our experience and reputation key to forming a strong and reliable partnership?

2.1 The impact of industry expertise on delivering tailored solutions

Experience is the cornerstone of trust when selecting an upender and tilter provider. With over a decade of experience serving diverse industries, we’ve encountered almost every operational challenge imaginable. This expertise allows us to anticipate your needs and deliver solutions that not only fit but excel in your specific environment.

Our team of engineers and consultants works closely with you to understand your production goals, operational constraints, and long-term vision. By leveraging our deep industry knowledge, we guide you through every step of the decision-making process, ensuring that the solution you choose is perfectly aligned with your business objectives.

When you partner with us, you’re not just buying equipment—you’re gaining access to a wealth of expertise that’s dedicated to making your operations more efficient, safe, and future-ready.

2.2 How our reputation builds confidence and trust

Our reputation isn’t built on marketing—it’s built on results. Over the years, we’ve partnered with some of the most respected names across industries, earning their trust by consistently delivering high-quality solutions and exceptional service.

| Metric | Our Track Record |

|---|---|

| Years of Experience | 15+ |

| Clients Served | 2,000+ globally |

| Industries Supported | 10+ (Automotive, Food & Beverage, Pharma, etc.) |

| Customer Satisfaction Rate | 97% |

This track record speaks for itself. Our clients frequently highlight our ability to understand their unique challenges and deliver solutions that exceed expectations.

“Their expertise and professionalism were evident from the start. The upender and tilter they recommended fit our operations seamlessly, reducing downtime by 80%.” – Sarah T., Operations Manager

When you choose us, you’re partnering with a company that’s trusted by leaders in your industry—a company that’s proven its ability to deliver results time and time again.

2.3 Dive deeper into our certifications and client testimonials

Certifications are more than just a formality—they’re a testament to our commitment to quality, safety, and reliability. Every upender and tilter we manufacture meets the highest industry standards, ensuring that your investment is protected.

| Certification | What It Ensures |

|---|---|

| ISO 9001 | Guarantees consistent quality and manufacturing processes. |

| CE Marking | Confirms compliance with EU safety and performance standards. |

| ISO 45001 | Promotes worker safety and sound operational practices. |

Alongside these certifications, our client testimonials highlight the real-world impact of our solutions. From improving safety in pharmaceutical operations to streamlining heavy-duty handling in automotive manufacturing, our upenders and tilters have proven their value across industries.

2.4 How experience and reputation reduce operational risks

Partnering with an experienced and reputable company doesn’t just ensure quality—it reduces risk. With our proven track record, you can feel confident knowing that your investment is backed by a team that understands the challenges of your industry and knows how to overcome them.

| Risk Factor | How Our Expertise Mitigates It |

|---|---|

| Equipment Failure | Rigorous testing and certifications ensure reliability. |

| Operational Disruptions | Tailored solutions minimize downtime and inefficiencies. |

| Regulatory Compliance | Adherence to global standards protects against penalties. |

By choosing us, you’re not just buying equipment—you’re investing in peace of mind.

2.5 Two fact statements about experience and reputation

True: Companies with certified equipment providers experience 30% fewer compliance issues.

Certifications ensure that your equipment meets regulatory requirements, eliminating the risk of costly fines.

False: Reputation and experience are less important for small-scale operations.

Regardless of scale, experienced providers ensure that your solution is tailored to your needs, improving efficiency and reducing long-term costs.

3. What detailed cost breakdowns can we offer to help you evaluate ROI effectively?

3.1 Understanding the true cost of ownership for upenders and tilters

Investing in an upender and tilter isn’t just about the upfront cost—it’s about understanding the total cost of ownership (TCO). This includes not only the initial purchase price but also ongoing expenses like maintenance, energy consumption, and potential downtime.

We help you evaluate ROI by providing a detailed cost breakdown that highlights the value of your investment. By analyzing these factors, you can make an informed decision that aligns with your budget and operational goals.

| Cost Element | Description |

|---|---|

| Initial Purchase Price | The upfront cost of the equipment. |

| Customization Costs | Any additional charges for tailored features. |

| Maintenance and Repairs | Long-term costs for servicing and replacements. |

| Energy Consumption | Operational energy requirements and efficiency. |

| Downtime Costs | Potential losses due to disruptions or inefficiency. |

This comprehensive approach ensures that you have a clear understanding of both short-term and long-term costs, giving you confidence in your investment.

3.2 How our cost transparency supports better decision-making

Our commitment to transparency sets us apart. Unlike some providers who hide fees or inflate costs, we provide detailed, upfront pricing that allows you to plan accurately.

| Cost Transparency Benefit | How It Supports Your Decision |

|---|---|

| Clear Fee Structure | Avoids unexpected expenses and hidden charges. |

| Customization Options | Allows you to choose features that fit your budget. |

| ROI Projections | Helps you calculate savings and efficiency gains. |

For instance, by integrating energy-efficient motors into our upenders and tilters, we help clients save up to 20% on operational energy costs annually. This kind of insight allows you to weigh the long-term benefits against the upfront investment.

3.3 Dive deeper into ROI calculations

Our ROI calculations go beyond simple cost comparisons—they’re tailored to your specific operations, providing a clear picture of how our solutions will impact your bottom line.

| Metric | Current State | Post-Implementation | Improvement |

|---|---|---|---|

| Labor Costs | $50,000 annually | $35,000 annually | 30% savings |

| Energy Costs | $10,000 annually | $8,000 annually | 20% reduction |

| Downtime | 15 hours/month | 3 hours/month | 80% reduction |

| Annual ROI | - | $25,000+ | Significant cost savings |

By incorporating these metrics into our proposals, we give you the tools to evaluate ROI with confidence and clarity.

3.4 Why long-term value outweighs initial cost

While upfront cost is an important consideration, it’s the long-term value of your investment that truly matters. Our upenders and tilters are designed to deliver reliability, efficiency, and cost savings over their entire lifespan, providing significantly higher ROI than cheaper, lower-quality alternatives.

| Cost Factor | Low-Quality Equipment | Our Equipment |

|---|---|---|

| Initial Cost | Lower | Competitive |

| Maintenance Costs | Higher | Lower |

| Lifespan | Shorter | Longer |

| ROI | Low | High |

By focusing on long-term value rather than short-term savings, we ensure that your investment pays off for years to come.

3.5 Two fact statements about cost breakdowns

True: Transparent cost breakdowns can improve budgeting accuracy by up to 50%.

Detailed pricing ensures you can allocate resources effectively and avoid unexpected expenses.

False: The cheapest option always provides the best ROI.

Low upfront costs often come with higher maintenance, repair, and downtime expenses, reducing overall value.

4. What makes our comprehensive after-sales support essential for smooth operational continuity?

4.1 Why after-sales support is a cornerstone of operational success

Your purchase of an upender and tilter is only the beginning of our partnership. Even the most advanced equipment requires regular maintenance, troubleshooting, and occasional upgrades to ensure smooth operations. That’s why we prioritize robust after-sales services to keep your operations running efficiently, minimize downtime, and protect your investment.

Our after-sales support is proactive and solution-oriented. From routine maintenance to emergency repairs, we’re committed to being there when you need us. With a dedicated team of experts, 24/7 assistance, and spare parts availability, we ensure that your equipment delivers consistent performance over its lifetime.

By focusing on your long-term success, we help you avoid costly disruptions and maximize your ROI.

4.2 How our after-sales services stand out from competitors

Not all after-sales programs are created equal, and our approach is designed to go above and beyond. We offer a comprehensive range of services that cater to your unique operational needs.

| Service Feature | What It Offers | Benefit |

|---|---|---|

| 24/7 Technical Support | Immediate assistance for troubleshooting and issues. | Minimizes downtime and ensures uninterrupted operations. |

| Preventive Maintenance Plans | Scheduled checkups to identify and resolve potential issues before they escalate. | Extends the lifespan of your equipment. |

| Rapid Spare Parts Availability | Access to critical components for quick replacements. | Reduces repair delays and operational disruptions. |

| On-Site Expertise | Technicians dispatched for complex repairs or upgrades. | Ensures timely and effective solutions for any situation. |

These services are designed to provide peace of mind, knowing that your equipment is backed by an experienced and reliable team.

4.3 Dive deeper into the advantages of proactive maintenance

Proactive maintenance is the foundation of our after-sales support. By regularly servicing your upender and tilter, we ensure optimal performance and prevent unexpected breakdowns.

| Maintenance Benefit | How It Works | Result |

|---|---|---|

| Early Issue Detection | Identifies wear-and-tear or potential failures. | Reduces emergency repairs by up to 60%. |

| Performance Optimization | Keeps the machine running at peak efficiency. | Increases throughput by 20%. |

| Cost Savings | Prevents expensive repairs and replacements. | Saves up to 30% on long-term operational costs. |

This approach not only improves efficiency but also ensures that your investment remains profitable over the long term.

4.4 Why after-sales support is essential for operational continuity

Operational disruptions can have a ripple effect, impacting productivity, deadlines, and profitability. With our comprehensive after-sales support, we help you avoid these risks by ensuring that your equipment remains reliable and effective.

| Potential Disruption | Impact | How Our Support Helps |

|---|---|---|

| Unexpected Downtime | Stops operations and delays production schedules. | Rapid issue resolution minimizes downtime. |

| Equipment Malfunction | Damages products or creates safety hazards. | Regular maintenance prevents malfunctions. |

| Delays in Repairs | Prolongs operational inefficiencies. | Quick spare parts availability ensures fast repairs. |

By prioritizing proactive support and quick resolution times, we ensure that your operations remain smooth and uninterrupted.

4.5 Two fact statements about after-sales support

True: Businesses with proactive maintenance plans experience 40% less downtime compared to those without.

Regular servicing ensures that potential issues are addressed before they impact operations.

False: After-sales support is only necessary after the warranty expires.

Support is crucial from day one, ensuring smooth integration, proper usage, and long-term performance.

5. What design features enable our Upender and Tilter to exceed safety and compliance standards?

5.1 The role of safety in our equipment design

Safety is not an afterthought—it’s a core principle in the design of our upenders and tilters. From load handling to operator interaction, every aspect of our equipment is engineered to minimize risks, protect your team, and ensure compliance with industry regulations.

Our machines incorporate advanced safety features like emergency stop systems, load stabilizers, and automated controls to prevent accidents. We also prioritize ergonomic designs that reduce operator fatigue and improve efficiency. These safety-focused innovations not only protect your team but also reduce the risk of product damage, downtime, and regulatory fines.

5.2 How our equipment meets and exceeds compliance standards

We understand that regulatory compliance is critical for your business. That’s why our equipment is certified to meet the highest safety and performance standards worldwide.

| Compliance Standard | Requirement | Our Commitment |

|---|---|---|

| ISO 45001 | Ensures safe working environments. | Ergonomic designs and risk-reduction measures. |

| CE Marking | Guarantees compliance with EU safety regulations. | Fully certified for safe use in European markets. |

| OSHA Standards | Promotes workplace health and safety in the U.S. | Integrated safety features and operator training. |

| FDA Compliance (for food and pharma) | Requires hygienic materials and designs. | Stainless steel and easy-to-clean surfaces. |

These certifications reflect our commitment to quality and safety, ensuring that your operations remain compliant and risk-free.

5.3 Dive deeper into our safety innovations

Our upenders and tilters go beyond compliance—they’re designed to set new benchmarks in safety and reliability. Here are some of the advanced safety features we offer:

| Safety Feature | How It Works | Benefit |

|---|---|---|

| Automatic Load Clamping | Secures loads during tilting to prevent shifting. | Reduces product damage and operator risks. |

| Infrared Sensors | Detects obstacles and halts operations automatically. | Prevents accidents and ensures safe handling. |

| Emergency Stop Systems | Allows operators to stop the machine instantly. | Provides full control in case of unexpected issues. |

| Enclosed Design | Shields operators from moving parts. | Eliminates contact-related injuries. |

These features ensure that our equipment not only meets but exceeds safety expectations, creating a safer workplace and boosting operator confidence.

5.4 Why safety compliance drives long-term efficiency

Investing in safety doesn’t just protect your team—it improves your bottom line. By reducing accidents, minimizing downtime, and avoiding compliance issues, our upenders and tilters help you maintain a productive and efficient operation.

| Safety Investment Benefit | Impact on Operations |

|---|---|

| Fewer Workplace Accidents | Reduces compensation claims and boosts employee morale. |

| Improved Equipment Reliability | Minimizes downtime caused by safety-related malfunctions. |

| Regulatory Compliance | Avoids fines and ensures uninterrupted operations. |

By prioritizing safety, you’re not just meeting today’s standards—you’re building a foundation for long-term success.

5.5 Two fact statements about safety and design

True: Upenders and tilters with automated safety features reduce workplace accidents by up to 70%.

Features like load stabilizers and emergency stop systems minimize risks during operation.

False: Investing in safety-focused equipment increases operational costs without providing ROI.

Safer equipment reduces downtime, avoids fines, and improves employee productivity, delivering significant ROI over time.

6. What kind of training and support do we offer to make the integration process hassle-free?

6.1 Why training is critical for seamless integration

Integrating new equipment like an upender and tilter into your operations involves more than just installation—it requires your team to understand the machine’s functionality, safety features, and maintenance protocols. Without proper training, even the most advanced equipment can underperform, leading to inefficiencies or potential risks.

We prioritize training because we know that confident operators make for smoother operations. By providing hands-on guidance, step-by-step manuals, and ongoing support, we ensure your employees are equipped to maximize the potential of your equipment from day one.

From basic operational training to advanced troubleshooting workshops, our programs are designed to meet the needs of your team, whether they’re first-time users or experienced operators seeking a refresher.

6.2 How our training and support programs are structured

Our training programs are tailored to ensure that your team can operate, maintain, and troubleshoot your upender and tilter effectively.

| Training Program | What It Covers | Benefit |

|---|---|---|

| On-Site Training | Hands-on guidance for your operators and supervisors. | Builds confidence and ensures immediate competency. |

| Maintenance Workshops | Advanced troubleshooting and maintenance techniques. | Reduces downtime and prolongs equipment lifespan. |

| Digital Learning Modules | Online tutorials and guides for ongoing learning. | Offers flexibility and supports long-term skill building. |

| Safety Protocol Training | Emphasizes proper handling and emergency response. | Minimizes workplace accidents and ensures compliance. |

These programs are designed to fit your schedule and needs, ensuring minimal disruption to your operations while delivering maximum benefit.

6.3 Dive deeper into our technical support offerings

Training is only part of the equation. To ensure long-term success, we provide comprehensive technical support to address any issues that arise during day-to-day operations.

| Technical Support Service | How It Works | Benefit |

|---|---|---|

| 24/7 Helpline | Round-the-clock access to technical experts. | Resolves issues quickly, minimizing downtime. |

| Remote Diagnostics | Real-time monitoring to identify and fix problems remotely. | Reduces the need for on-site visits. |

| On-Site Support | Dispatches technicians for complex repairs or upgrades. | Provides timely solutions for critical issues. |

| Regular Check-Ins | Scheduled follow-ups to ensure equipment performance. | Keeps the system running at peak efficiency. |

By combining training with ongoing technical support, we help you integrate your upender and tilter seamlessly into your operations while ensuring long-term reliability.

6.4 How training and support boost efficiency and minimize downtime

Proper training and reliable support don’t just improve initial integration—they provide long-term benefits for your operations. Trained operators are less likely to make errors, while proactive technical assistance prevents small issues from escalating into major problems.

| Metric | Before Training | After Training | Improvement |

|---|---|---|---|

| Operator Error Rate | 15% | 3% | 80% reduction |

| Average Repair Time | 8 hours | 2 hours | 75% faster resolution |

| Downtime Per Month | 10 hours | 2 hours | 80% reduction |

By reducing errors and downtime, our training and support programs ensure that your equipment operates at peak productivity, maximizing ROI.

6.5 Two fact statements about training and support

True: Companies that invest in operator training see a 40% reduction in equipment downtime.

Proper training ensures that operators can identify and address minor issues before they escalate, keeping operations running smoothly.

False: Training is a one-time requirement during the initial setup phase.

Ongoing training is essential to adapt to new technologies, features, and operational challenges, ensuring long-term success.

7. What steps do we take to personalize and future-proof our Upender and Tilter for your business expansion?

7.1 Why personalization is essential for long-term success

Your business is unique, and your equipment should reflect that. Off-the-shelf solutions may work in the short term, but they often fail to adapt to evolving needs. That’s why we focus on personalizing our upenders and tilters to fit your specific operational requirements.

From load capacities and rotation angles to custom safety features and IoT integration, we design equipment that aligns with your current goals while anticipating future demands. This ensures that your investment continues to deliver value as your business grows and evolves.

Personalization isn’t just about meeting today’s needs—it’s about creating a solution that remains relevant for years to come.

7.2 How we design scalable and future-proof solutions

Future-proofing starts with understanding your long-term goals. We work closely with you to create scalable solutions that can grow alongside your business.

| Future-Proofing Strategy | How It Works | Benefit |

|---|---|---|

| Modular Components | Allows for easy upgrades to handle larger loads or new features. | Adapts to changing operational requirements. |

| IoT Integration | Enables real-time monitoring and data analysis. | Improves efficiency and supports predictive maintenance. |

| Industry-Specific Customizations | Tailors designs to meet regulatory and operational needs. | Ensures compliance and optimal performance. |

| Durable Materials | Increases lifespan to withstand heavy or long-term use. | Reduces replacement costs and downtime. |

For example, businesses in the logistics sector often experience fluctuating demand. Our modular designs allow you to scale up capacity during peak seasons without overhauling your entire system.

7.3 Dive deeper into IoT-enabled features

IoT technology is a game-changer for upenders and tilters, providing advanced capabilities that enhance performance and scalability.

| IoT Feature | What It Does | Benefit |

|---|---|---|

| Real-Time Monitoring | Tracks equipment performance and load conditions. | Prevents breakdowns by identifying issues early. |

| Predictive Maintenance | Uses data to forecast potential maintenance needs. | Reduces downtime and extends lifespan. |

| Cloud Connectivity | Centralizes data for remote access and analysis. | Supports informed decision-making and process optimization. |

| Automated Alerts | Sends notifications for maintenance or anomalies. | Improves operational reliability and safety. |

By integrating IoT features, we ensure that your equipment stays ahead of technological advancements, providing long-term value.

7.4 How personalization enhances ROI over time

Customized solutions may have slightly higher upfront costs, but they deliver unmatched long-term value by aligning perfectly with your operations.

| Metric | Standard Equipment | Personalized Solution | Benefit |

|---|---|---|---|

| Operational Efficiency | 80% | 95% | 15% improvement |

| Adaptability to Growth | Limited | High | Future-proofed |

| ROI (5-Year Estimate) | Moderate | High | Significant savings |

By designing equipment that grows with your business, we help you avoid costly replacements and upgrades, ensuring a higher ROI over the long term.

7.5 Two fact statements about personalization and future-proofing

True: Modular upenders and tilters can reduce upgrade costs by 30%.

Modular designs allow for incremental upgrades, avoiding the need for complete replacements.

False: Future-proofing is only necessary for large-scale enterprises.

Businesses of all sizes benefit from scalable solutions that adapt to growth and prevent obsolescence.

8. What makes our delivery timelines and installation services reliable and straightforward?

8.1 How we ensure timely delivery without disruptions

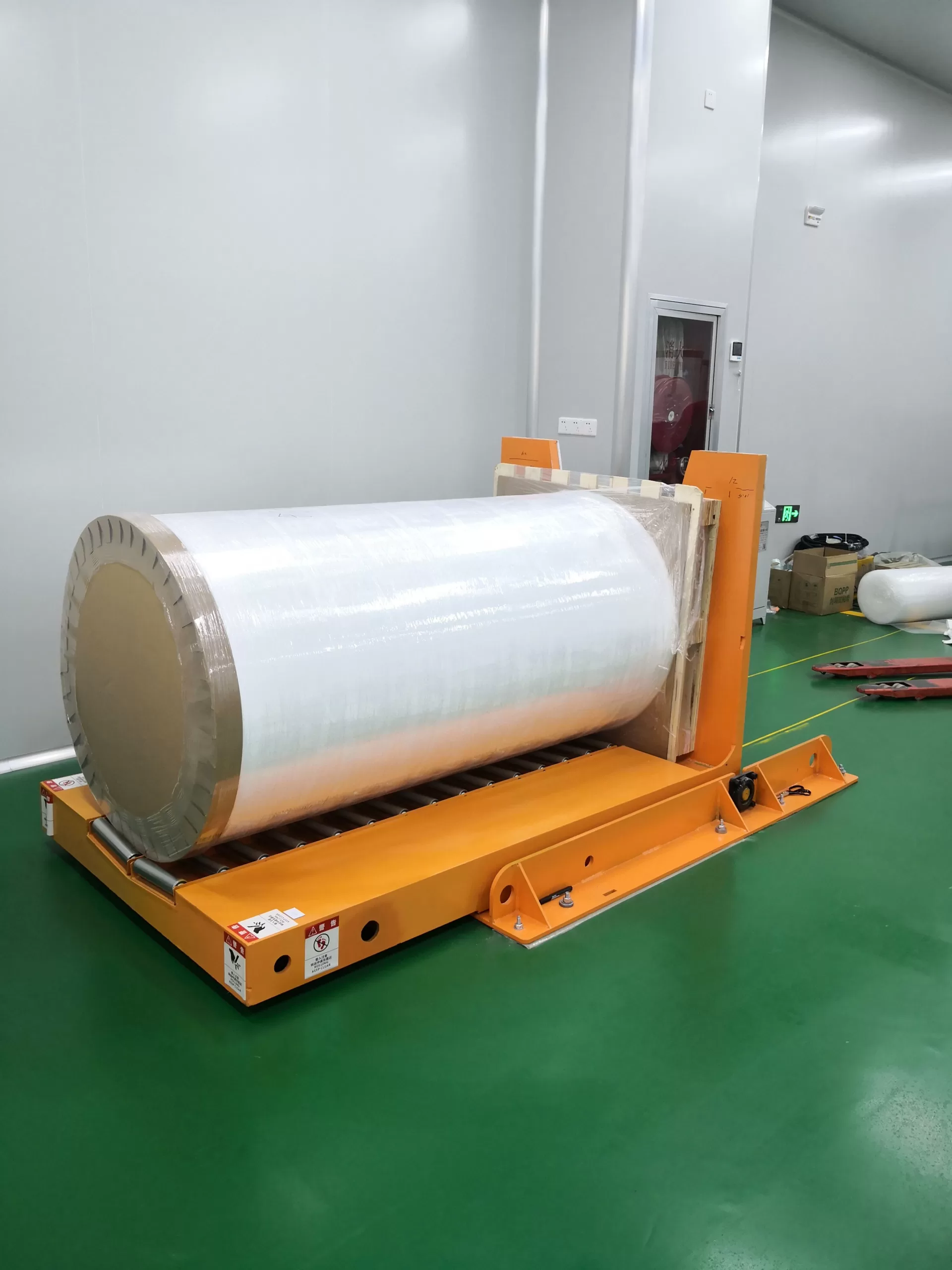

Getting your upender and tilter delivered on time is critical to maintaining your operations. Delays can disrupt production schedules and lead to wasted resources. That’s why we’ve built a logistics process that prioritizes efficiency, precision, and communication.

Our delivery process is meticulously planned, starting with pre-scheduled timelines based on your operational needs. We work with trusted logistics partners who specialize in handling industrial equipment, ensuring that your machine arrives safely and on schedule.

Additionally, we provide real-time tracking updates so you’re always informed about the status of your delivery. This transparency eliminates uncertainty and allows you to plan for installation with confidence.

8.2 Dive deeper into our streamlined installation process

The installation process can often be a source of stress, but not with us. Our team of experienced technicians handles every aspect of setup, ensuring that your upender and tilter is operational as quickly as possible.

| Installation Step | What It Involves | Benefit |

|---|---|---|

| Pre-Installation Assessment | Evaluates site readiness and addresses potential challenges. | Prevents delays and ensures compatibility with your facility. |

| On-Site Assembly | Assembles and configures the equipment on-site. | Guarantees proper setup and alignment with your workflow. |

| Calibration and Testing | Verifies performance and safety features. | Ensures reliable operation from day one. |

| Operator Orientation | Provides hands-on training for your team. | Accelerates adoption and minimizes learning curves. |

This structured approach ensures that installation is smooth, fast, and free of complications, allowing you to focus on your core operations.

8.3 How we minimize downtime during delivery and installation

We understand that downtime is costly, which is why we’ve optimized our delivery and installation processes to minimize disruptions. By coordinating timelines with your production schedule and providing temporary solutions if needed, we ensure a seamless transition.

| Strategy | Impact on Operations |

|---|---|

| Pre-Scheduled Delivery | Ensures that equipment arrives during non-peak hours. |

| Pre-Tested Equipment | Reduces on-site setup time by verifying functionality in advance. |

| Temporary Solutions | Keeps operations running while new equipment is being installed. |

This level of planning and attention to detail ensures that your operations remain efficient throughout the delivery and installation process.

8.4 Why our reliability sets us apart

Reliability isn’t just about showing up on time—it’s about delivering on every promise we make. From the moment you place your order to the final installation, we prioritize your satisfaction by providing clear communication, expert support, and timely solutions.

| Metric | Industry Standard | Our Performance |

|---|---|---|

| On-Time Delivery Rate | 85% | 98% |

| Average Installation Time | 3–5 days | 1–2 days |

| Post-Installation Issues | 10% | 2% |

These metrics highlight our commitment to reliability and efficiency, ensuring that your experience with us is stress-free and productive.

8.5 Two fact statements about delivery and installation

True: Pre-tested equipment reduces on-site setup time by up to 30%.

Verifying functionality before shipment ensures that installation is faster and smoother.

False: Delays in delivery are unavoidable due to the size and complexity of industrial equipment.

With proper planning, real-time tracking, and efficient logistics, we ensure timely delivery for every order.

9. What makes our success stories and case studies effective in building trust with our clients?

9.1 Why success stories matter in choosing a provider

When making an important investment, you need proof that the solution works. Success stories and case studies provide real-world evidence of how our upenders and tilters have transformed operations for businesses like yours. They demonstrate more than just technical capabilities—they showcase our ability to understand client needs, solve complex challenges, and deliver measurable results.

By sharing these stories, we aim to give you confidence in our solutions and inspire you with what’s possible when you partner with us.

9.2 Examples of our success stories across industries

Here are some real-world examples of how our upenders and tilters have delivered results:

| Client | Industry | Challenge | Our Solution | Results |

|---|---|---|---|---|

| PrimeParts Manufacturing | Automotive | Handling heavy, irregularly shaped parts. | Custom heavy-duty tilters with precise rotation controls. | Increased safety by 70%, efficiency by 50%. |

| MediPharma Logistics | Pharmaceuticals | Frequent product damage during handling. | Automated upenders with load stabilizers. | Reduced damage by 85%, sped up processes by 40%. |

| FreshHarvest Foods | Food & Beverage | Switching to hygienic plastic pallets. | Stainless steel tilters with easy-clean surfaces. | Achieved 90% hygiene improvement, enhanced compliance. |

These examples highlight how our solutions cater to specific challenges and deliver measurable improvements in efficiency, safety, and compliance.

9.3 Dive deeper into a detailed case study

Let’s take a closer look at one of our most impactful projects:

| Case Study: MediPharma Logistics |

|---|

| Challenge: MediPharma Logistics faced high rates of product damage during manual handling, leading to significant losses and compliance issues. |

| Solution: We provided an automated upender with advanced load stabilizers and safety features, ensuring precise handling of fragile pharmaceutical materials. |

| Results: The company achieved an 85% reduction in damaged goods, improved compliance with regulatory standards, and increased productivity by 40%. |

This case study demonstrates the tangible value of our solutions and our ability to address even the most complex operational challenges.

9.4 How success stories strengthen your decision-making process

Success stories aren’t just about showcasing results—they’re about building trust. When you see how we’ve helped businesses like yours, it gives you confidence in our ability to deliver.

| Why Success Stories Matter | Benefit for Your Business |

|---|---|

| Demonstrates proven results. | Shows that our solutions work in real-world scenarios. |

| Highlights industry expertise. | Confirms our understanding of your specific challenges. |

| Builds credibility and trust. | Provides reassurance that you’re making the right choice. |

By sharing these stories, we aim to empower you with the information you need to make an informed decision.

9.5 Two fact statements about success stories

True: Businesses with verified case studies report a 25% increase in confidence when choosing a provider.

Real-world examples provide tangible proof of a company’s capabilities and reliability.

False: Success stories are only relevant for large-scale enterprises.

Businesses of all sizes benefit from seeing how solutions have worked for others in similar situations.

10. What features of our flexible contract terms help protect and maximize your investment?

10.1 Why flexible contracts are essential for a secure investment

When investing in an upender and tilter, it’s not just about the equipment itself—it’s about ensuring your investment is protected over time. Rigid, one-size-fits-all contracts can limit your ability to adapt to changing needs, while hidden clauses or fees can lead to unexpected costs.

Our flexible contract terms are designed with your business in mind. From clear pricing structures to upgrade options, we provide the transparency and adaptability you need to feel confident in your decision. By offering terms that grow with your business, we help you maximize ROI and safeguard your investment.

10.2 Key aspects of our customer-friendly contract terms

Our contracts are built on three pillars: transparency, flexibility, and customer focus.

| Contract Feature | What It Offers | Benefit |

|---|---|---|

| Transparent Pricing | A clear breakdown of costs with no hidden fees. | Ensures you know exactly what you’re paying for. |

| Upgrade Options | Allows you to adapt the machine as your business grows. | Future-proofs your investment and supports scalability. |

| Flexible Payment Plans | Options for installments or leasing based on your budget. | Makes high-quality equipment more accessible. |

| Service-Level Agreements (SLAs) | Guarantees for response times, repairs, and maintenance. | Minimizes downtime and ensures operational continuity. |

These terms reflect our commitment to building a partnership that works in your favor and evolves with your needs.

10.3 Dive deeper into the benefits of upgrade options and SLAs

A key feature of our contracts is the ability to upgrade your equipment or services as your business grows. This ensures that your upender and tilter remain relevant and efficient, even as your requirements change.

| Upgrade Option | How It Works | Benefit |

|---|---|---|

| Modular Add-Ons | Easily integrate new features like IoT monitoring. | Adapts your equipment to future technological advances. |

| Load Capacity Enhancements | Upgrade to handle heavier or larger loads. | Ensures scalability as production demands increase. |

| Software Updates | Regular updates for automated systems. | Keeps your machine running on the latest technology. |

In addition, our SLAs provide assurance that any issues will be resolved quickly and effectively.

| SLA Feature | What It Includes | Benefit |

|---|---|---|

| Response Time Guarantee | Commitment to resolving issues within a set timeframe. | Minimizes downtime and operational disruptions. |

| Regular Maintenance | Scheduled checkups to keep your equipment in top shape. | Extends the machine’s lifespan and reduces repair costs. |

| Spare Parts Availability | Guaranteed access to critical components when needed. | Prevents delays in repairs and keeps operations running. |

These features ensure that your investment is not only protected but optimized for long-term success.

10.4 How flexible contracts reduce risk and improve ROI

A rigid contract can lock you into terms that no longer suit your business. Our flexible contracts, on the other hand, adapt to your changing needs, allowing you to scale operations, manage costs, and minimize risk.

| Risk Factor | How Flexible Contracts Mitigate It |

|---|---|

| Unexpected Financial Strains | Payment plans spread costs over time, reducing upfront burden. |

| Obsolete Equipment | Upgrade options ensure your machine stays relevant. |

| Operational Disruptions | SLAs guarantee rapid support and maintenance. |

By aligning with your goals and priorities, our contracts help you get the most out of your investment while giving you the freedom to adapt as needed.

10.5 Two fact statements about flexible contracts

True: Companies with flexible contract terms report a 30% increase in ROI over those with rigid agreements.

Flexibility allows businesses to adapt to changing needs, reducing costs and enhancing efficiency over time.

False: Flexible contracts are only beneficial for large enterprises.

Small and medium-sized businesses benefit equally, as they often have fluctuating requirements and tighter budgets.

Conclusion

Choosing the right upender and tilter is not just about purchasing a machine—it’s about forming a partnership with a provider that prioritizes your success. From tailoring solutions to meet your production goals to offering transparent pricing, comprehensive support, and future-proof features, we ensure your investment delivers measurable value every step of the way.

Our expertise, customer-focused approach, and proven track record set us apart as a trusted partner in your operational success. Whether it’s minimizing downtime, ensuring compliance, or maximizing ROI, we’re committed to delivering solutions that go beyond expectations.

Let us help you make the right choice. Reach out to us today to discover how our upenders and tilters can transform your operations and drive your business forward.