How We Make Choosing the Right Automatic wire packing line Easy for You?

In today's fast-paced manufacturing environment, finding the perfect automatic wire packing line can be a daunting task. With countless options available and complex technical specifications to navigate, it's easy to feel overwhelmed and uncertain about making the right choice for your business.

But what if there was a way to simplify the process and ensure that you select the ideal solution for your unique production needs? At , we understand the challenges you face and have developed a comprehensive approach to make choosing the right automatic wire packing line easy and stress-free.

Our team of experienced professionals has spent years researching, designing, and refining our automatic wire packing lines to meet the diverse requirements of businesses like yours. We've combined cutting-edge technology with practical insights gained from working closely with our clients to create solutions that deliver unparalleled performance, reliability, and efficiency.

1. What production needs are perfectly satisfied by our Automatic wire packing line's features?

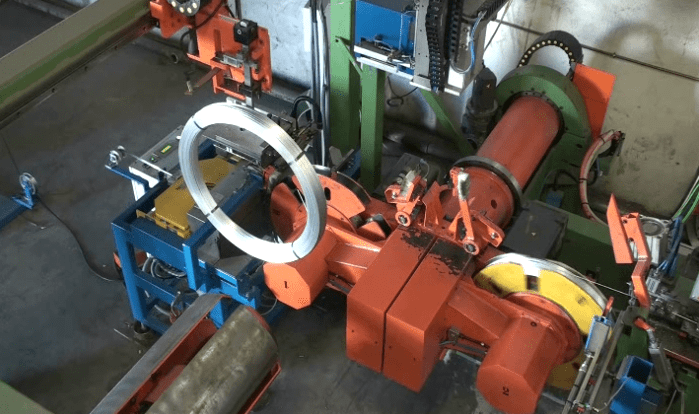

1.1 High-speed, precision packing for increased productivity

One of the key features of our automatic wire packing line is its ability to achieve high-speed, precision packing, enabling you to significantly increase your production output. Our advanced systems are designed to handle a wide range of wire types and sizes, ensuring accurate and consistent packing every time.

Key benefits of our high-speed, precision packing include:

Processing speeds of up to 120 meters per minute

Accurate length measurement with tolerances of ±0.5mm

Consistent wire tension control for optimal packing density

Automatic wire cutting and sealing for efficient packaging

By leveraging these capabilities, you can streamline your packing process, reduce manual labor requirements, and boost your overall productivity, allowing you to meet growing customer demands with ease.

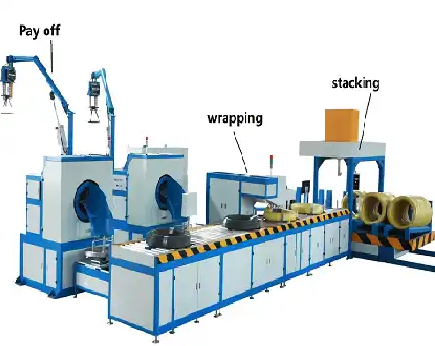

1.2 Flexible configuration options for diverse applications

We understand that every business has unique packing requirements, which is why our automatic wire packing lines offer flexible configuration options to suit a wide range of applications. Whether you need to pack single wires, multi-wire assemblies, or complex harnesses, our modular design allows you to customize your system to meet your specific needs.

Some of the configuration options available include:

Adjustable wire guides and rollers for different wire diameters

Interchangeable packing heads for various packing materials (e.g., paper, plastic, foam)

Modular conveyor systems for easy integration with existing production lines

Optional accessories such as printing units, labeling systems, and more

This flexibility ensures that our automatic wire packing line can adapt to your current and future production requirements, providing a future-proof solution that grows with your business.

1.3 Intelligent control systems for optimized performance

To further enhance the performance and reliability of our automatic wire packing lines, we've integrated intelligent control systems that monitor and optimize various process parameters in real-time. These advanced control systems ensure consistent packing quality, minimize downtime, and provide valuable data insights for continuous improvement.

Key features of our intelligent control systems include:

PLC-based control with intuitive HMI for easy operation

Real-time monitoring of wire tension, speed, and packing quality

Automatic fault detection and diagnosis for quick troubleshooting

Remote access and data logging for performance analysis and optimization

By leveraging these intelligent control systems, you can achieve optimal performance, reduce waste, and gain a competitive edge in your industry.

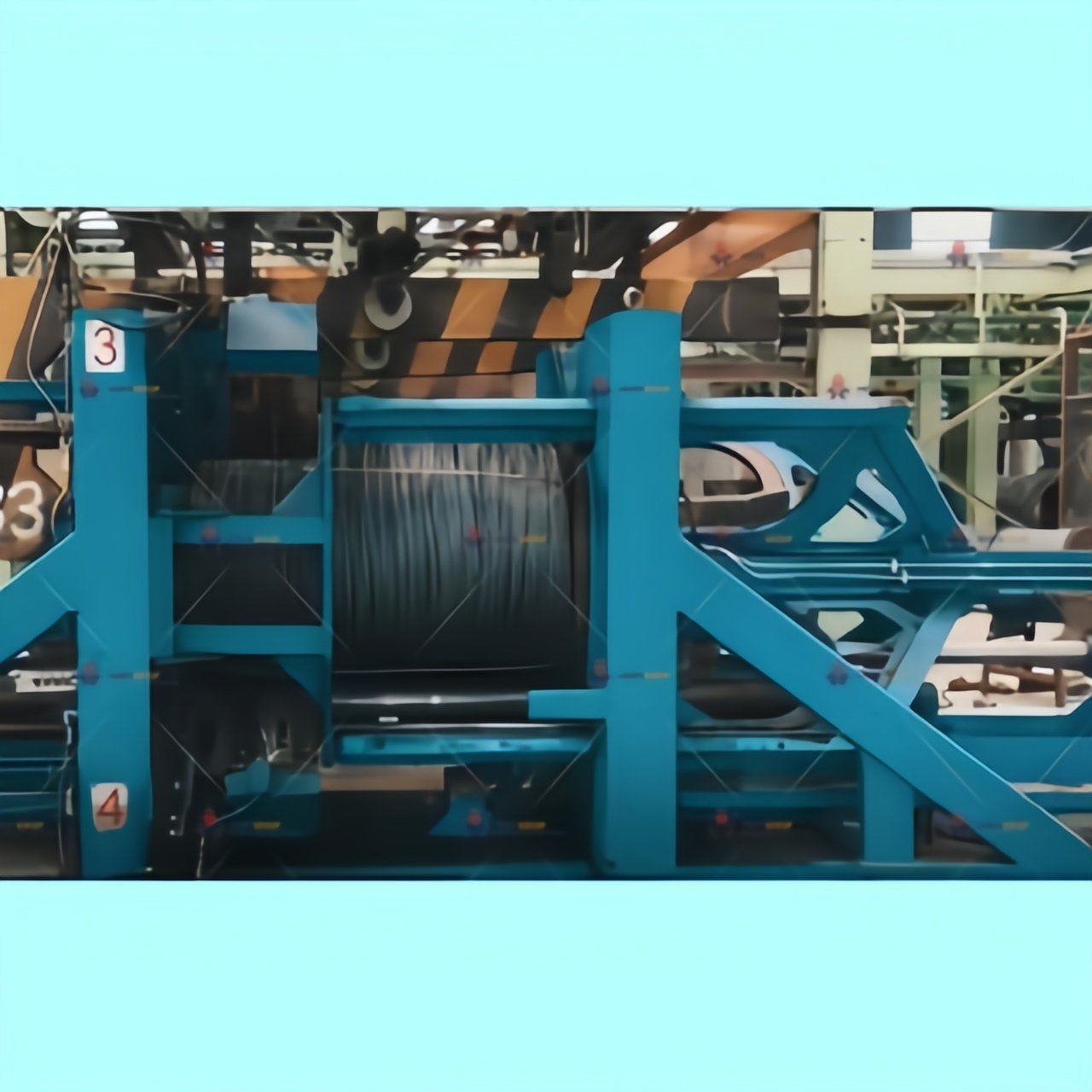

1.4 Robust construction for demanding production environments

We recognize that automatic wire packing lines often operate in demanding production environments, facing challenges such as high temperatures, dust, and continuous operation. To ensure maximum durability and reliability, our systems are built with robust, industrial-grade components that can withstand even the toughest conditions.

Some of the key construction features of our automatic wire packing lines include:

Heavy-duty steel frames for superior structural integrity

IP65-rated electrical components for protection against dust and moisture

High-quality, wear-resistant materials for critical components (e.g., rollers, guides, cutting blades)

Corrosion-resistant finishes for long-lasting performance

With this robust construction, our automatic wire packing lines deliver consistent, reliable performance year after year, minimizing maintenance requirements and maximizing your return on investment.

True Fact Statement: Our automatic wire packing line's features, including high-speed precision packing, flexible configuration options, intelligent control systems, and robust construction, perfectly satisfy a wide range of production needs, enabling businesses to increase productivity, adapt to diverse applications, optimize performance, and thrive in demanding environments.

False Fact Statement: Our automatic wire packing lines are one-size-fits-all solutions with limited configuration options, basic control systems, and flimsy construction, making them unsuitable for diverse applications and demanding production environments.

2. How does our combination of experience and trustworthiness guarantee a successful collaboration?

2.1 Extensive industry expertise and proven track record

When you choose FHOPE as your automatic wire packing line provider, you gain access to a wealth of industry expertise and a proven track record of success. Our team has decades of combined experience in designing, manufacturing, and implementing wire packing solutions for businesses across various sectors, giving us a deep understanding of the unique challenges and requirements you face.

Some of the key areas where our expertise shines include:

Optimizing packing processes for specific wire types and applications

Integrating automatic wire packing lines with existing production systems

Developing custom solutions for unique packing requirements

Providing expert guidance and support throughout the entire project lifecycle

By leveraging our extensive industry expertise, we can help you avoid common pitfalls, overcome complex challenges, and achieve your production goals more efficiently and effectively.

2.2 Long-standing partnerships with satisfied clients

Over the years, we've had the privilege of working with numerous clients across different industries, establishing long-standing partnerships built on trust, collaboration, and shared success. Our commitment to delivering exceptional results and providing outstanding customer service has earned us a reputation as a reliable and trustworthy partner.

Some of the benefits our clients have experienced include:

Increased productivity and output, often exceeding initial targets

Reduced labor costs and improved worker safety

Enhanced packing quality and consistency, leading to fewer customer complaints

Seamless integration with existing systems and processes

Responsive, knowledgeable support throughout the project and beyond

These successful collaborations demonstrate our ability to understand our clients' unique needs, develop tailored solutions, and deliver measurable results that drive business growth and success.

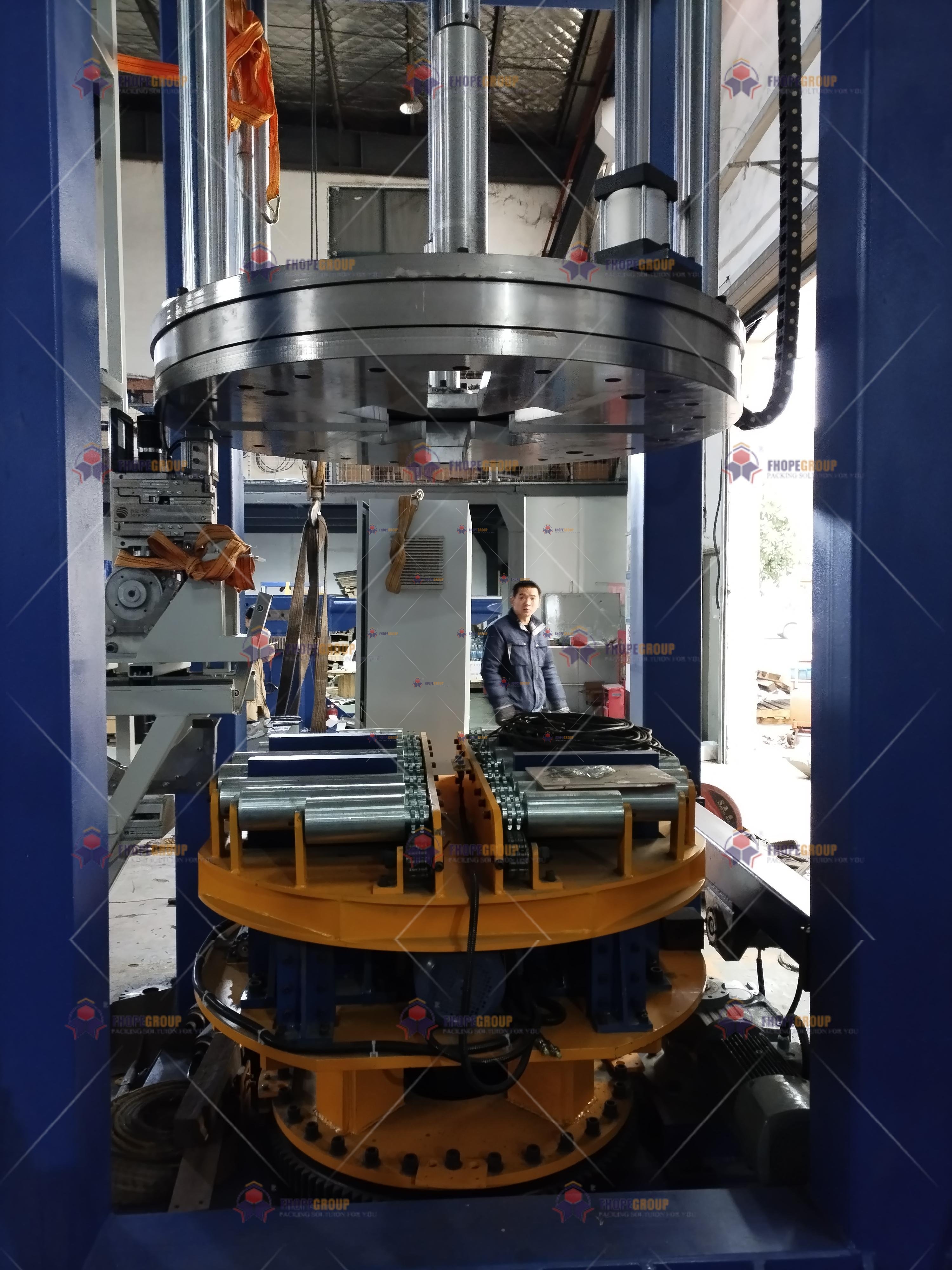

2.3 Rigorous quality control and testing procedures

To ensure that every automatic wire packing line we deliver meets the highest standards of quality and reliability, we employ rigorous quality control and testing procedures throughout the entire manufacturing process. From component selection to final system integration, our experienced quality assurance team meticulously inspects and tests each aspect of the system to guarantee optimal performance.

Our quality control and testing procedures include:

Strict supplier qualification and material inspection processes

In-process quality checks at critical manufacturing stages

Comprehensive functional testing of individual components and sub-systems

Full system integration testing under simulated production conditions

Detailed documentation and traceability for all quality control activities

By adhering to these stringent quality control measures, we can confidently deliver automatic wire packing lines that provide reliable, consistent performance and meet or exceed your expectations.

2.4 Continuous improvement and innovation

At FHOPE, we believe that success is an ongoing journey, not a final destination. That's why we foster a culture of continuous improvement and innovation, constantly seeking ways to enhance our products, processes, and services to better serve our clients.

Some of the ways we drive continuous improvement and innovation include:

Regular reviews and analysis of customer feedback and performance data

Ongoing research and development to incorporate new technologies and best practices

Collaboration with industry partners and experts to share knowledge and insights

Encouraging employee-driven innovation through suggestion programs and cross-functional teams

By embracing continuous improvement and innovation, we ensure that our automatic wire packing lines remain at the forefront of the industry, delivering cutting-edge solutions that help our clients stay ahead of the curve.

True Fact Statement: Our combination of extensive industry expertise, proven track record, long-standing client partnerships, rigorous quality control, and commitment to continuous improvement and innovation guarantees a successful collaboration that delivers measurable results and exceeds expectations.

False Fact Statement: We are a new, inexperienced player in the automatic wire packing line market, with no proven track record, quality control measures, or commitment to innovation, making us a risky choice for businesses seeking a reliable and trustworthy partner.

3. How can our transparent pricing help you confidently assess your return on investment?

3.1 Detailed, itemized quotes for clear cost understanding

At FHOPE, we believe in providing transparent, easy-to-understand pricing that allows you to make informed decisions about your investment in an automatic wire packing line. Our detailed, itemized quotes break down all costs associated with your project, giving you a clear picture of what you're paying for and how it contributes to the overall solution.

Our quotes typically include:

Base system price, including all standard components and features

Itemized costs for any optional accessories or customizations

Shipping, installation, and commissioning fees

Training and support services included in the initial purchase

Applicable taxes and duties

By providing this level of detail, we empower you to understand the value of each component and service, compare costs with other providers, and make confident decisions about your investment.

3.2 Competitive pricing without compromising quality

We understand that cost is a critical factor in any investment decision, which is why we strive to offer competitive pricing without compromising on the quality or performance of our automatic wire packing lines. Our lean manufacturing processes, strategic supplier relationships, and continuous improvement initiatives allow us to optimize costs while maintaining the highest standards of excellence.

Some of the ways we ensure competitive pricing include:

Streamlined production processes that minimize waste and inefficiencies

Bulk purchasing of high-quality components to secure favorable pricing

Modular system design that allows for cost-effective customization

Continuous value engineering to identify cost-saving opportunities without sacrificing quality

By striking the right balance between cost and quality, we provide automatic wire packing lines that deliver maximum value for your investment, helping you achieve your production goals without breaking the bank.

3.3 Customizable financing and leasing options

We recognize that every business has unique financial circumstances and budgetary constraints, which is why we offer customizable financing and leasing options to make investing in an automatic wire packing line more accessible and manageable. Our flexible payment plans allow you to spread the cost of your investment over time, aligning with your cash flow and revenue projections.

Some of the financing and leasing options we offer include:

Outright purchase with flexible payment terms

Operating lease with low monthly payments and option to purchase at end of term

Finance lease with fixed monthly payments and ownership at end of term

Rental agreements for short-term or seasonal production needs

By providing these customizable financing and leasing options, we help you acquire the automatic wire packing line you need without placing undue strain on your financial resources, enabling you to invest in your business's growth and success.

3.4 Transparent total cost of ownership analysis

When evaluating the return on investment for an automatic wire packing line, it's essential to consider not just the initial purchase price, but the total cost of ownership (TCO) over the system's lifetime. At FHOPE, we provide transparent TCO analysis that takes into account all direct and indirect costs associated with owning and operating your wire packing line.

Our TCO analysis includes factors such as:

Initial purchase price and installation costs

Annual maintenance and spare parts costs

Energy consumption and utility costs

Labor costs associated with operating and maintaining the system

Potential downtime and repair costs over the system's lifetime

By providing this comprehensive TCO analysis, we help you understand the long-term financial implications of your investment, compare the costs and benefits of different options, and make data-driven decisions that maximize your return on investment.

True Fact Statement: Our transparent pricing, including detailed itemized quotes, competitive prices without compromising quality, customizable financing and leasing options, and transparent total cost of ownership analysis, enables you to confidently assess your return on investment and make informed decisions about acquiring an automatic wire packing line.

False Fact Statement: We provide opaque, confusing pricing with hidden costs, inflated prices that compromise quality, rigid payment terms, and no consideration for the total cost of ownership, making it difficult for you to assess the true value and return on investment of our automatic wire packing lines.

4. How can our all-inclusive after-sales assistance help you avoid operational disruptions?

4.1 Comprehensive training and knowledge transfer

Investing in an automatic wire packing line is just the first step towards achieving your production goals. To ensure that you can fully leverage the capabilities of your new system and avoid operational disruptions, we provide comprehensive training and knowledge transfer services as part of our all-inclusive after-sales assistance.

Our training and knowledge transfer services include:

On-site training for operators, maintenance staff, and supervisors

Hands-on demonstrations and practice sessions to build confidence and proficiency

Detailed documentation, including user manuals, troubleshooting guides, and best practice recommendations

Remote training and e-learning modules for ongoing skill development

Train-the-trainer programs to help you build in-house expertise

By investing in comprehensive training and knowledge transfer, we help you develop the skills and expertise needed to operate and maintain your automatic wire packing line effectively, minimizing the risk of errors, downtime, and operational disruptions.

4.2 Proactive maintenance and performance optimization

Regular maintenance and performance optimization are critical to ensuring the long-term reliability, efficiency, and productivity of your automatic wire packing line. As part of our all-inclusive after-sales assistance, we offer proactive maintenance and optimization services that help you avoid costly breakdowns and keep your system running at peak performance.

Our maintenance and optimization services include:

Scheduled preventive maintenance visits to inspect, clean, and tune your system

Remote monitoring and diagnostics to identify potential issues before they cause downtime

Performance audits and benchmarking to identify opportunities for improvement

Continuous optimization of system parameters to enhance speed, accuracy, and quality

Access to a global network of skilled technicians for rapid on-site support when needed

By taking a proactive approach to maintenance and performance optimization, we help you minimize unplanned downtime, extend the life of your equipment, and achieve sustainable improvements in productivity and quality.

[sub-heading featured image: A technician performing preventive maintenance on an automatic wire packing line, showcasing the importance of regular upkeep]

4.3 Rapid response support and troubleshooting

Despite the best efforts to prevent issues, unexpected problems can still arise, threatening to disrupt your operations and impact your bottom line. That's why our all-inclusive after-sales assistance includes rapid response support and troubleshooting services, ensuring that you can quickly resolve any issues and get your automatic wire packing line back up and running.

Our rapid response support and troubleshooting services include:

24/7 technical support hotline staffed by experienced engineers

Remote diagnostic tools to quickly identify the root cause of issues

On-site support from local technicians for hands-on troubleshooting and repair

Expedited spare parts delivery from strategically located warehouses worldwide

Temporary backup systems or components to minimize downtime during repairs

By providing rapid response support and troubleshooting services, we help you minimize the impact of unexpected issues, reduce downtime, and maintain continuous production, even in the face of challenges.

4.4 Continuous improvement and upgrade support

As your business grows and evolves, so too will your production requirements and challenges. To help you stay ahead of the curve and adapt to changing needs, our all-inclusive after-sales assistance includes continuous improvement and upgrade support services, ensuring that your automatic wire packing line remains a valuable asset for years to come.

Our continuous improvement and upgrade support services include:

Regular system audits and performance reviews to identify improvement opportunities

Consultation and recommendation on process optimization and best practices

Upgrade options for hardware, software, and accessories to enhance functionality and performance

Compatibility testing and integration support for new wire types, materials, or packing configurations

Collaborative innovation and development of custom solutions for unique challenges

By providing continuous improvement and upgrade support services, we help you future-proof your investment, adapt to changing market demands, and maintain a competitive edge in your industry.

True Fact Statement: Our all-inclusive after-sales assistance, including comprehensive training and knowledge transfer, proactive maintenance and performance optimization, rapid response support and troubleshooting, and continuous improvement and upgrade support, helps you avoid operational disruptions, maintain peak performance, and achieve long-term success with your automatic wire packing line.

False Fact Statement: Once you purchase an automatic wire packing line from us, you're on your own to deal with training, maintenance, troubleshooting, and upgrades, with no support or assistance from our team to help you avoid operational disruptions or achieve continuous improvement.

5. How does the design of our Automatic wire packing line prioritize surpassing safety and compliance standards?

5.1 Robust safety features and emergency stop systems

At FHOPE, the safety of your operators and the compliance of your production processes are our top priorities. That's why our automatic wire packing lines are designed with robust safety features and emergency stop systems that prioritize the well-being of your team and ensure adherence to the strictest industry standards.

Some of the key safety features incorporated into our design include:

Fully enclosed guarding with interlocked access doors to prevent accidental contact with moving parts

Light curtains and sensors to detect operator presence and automatically stop the system if a breach occurs

Redundant emergency stop buttons located at strategic points for quick and easy activation

Fail-safe brake systems to ensure controlled stopping and prevent unintended movement

Clear safety labeling and visual indicators to alert operators of potential hazards

By integrating these robust safety features and emergency stop systems, we help you create a safer working environment, reduce the risk of accidents and injuries, and ensure compliance with applicable safety regulations.

5.2 Ergonomic design for operator comfort and well-being

In addition to preventing accidents, our automatic wire packing lines are designed with operator comfort and well-being in mind. We understand that happy, healthy operators are more productive and engaged, which is why we prioritize ergonomic design principles that reduce physical strain and fatigue.

Some of the ergonomic design features incorporated into our systems include:

Adjustable workstation heights and positions to accommodate operators of different sizes

Cushioned flooring and anti-fatigue mats to reduce stress on feet and legs

Intuitive, easy-to-reach controls and displays to minimize reaching and twisting

Balanced, lightweight tools and accessories to reduce strain on hands and wrists

Adequate lighting and ventilation to create a comfortable working environment

By designing our automatic wire packing lines with ergonomics in mind, we help you create a more comfortable and productive work environment, reduce the risk of musculoskeletal disorders, and improve overall operator well-being.

5.3 Strict adherence to industry standards and regulations

To ensure that our automatic wire packing lines meet or exceed the highest standards of safety and quality, we maintain strict adherence to relevant industry standards and regulations. Our design and manufacturing processes are guided by a comprehensive understanding of the legal and regulatory landscape, ensuring that our systems are compliant and ready for integration into your production environment.

Some of the key industry standards and regulations we adhere to include:

ISO 12100: Safety of machinery - General principles for design - Risk assessment and risk reduction

IEC 60204-1: Safety of machinery - Electrical equipment of machines - Part 1: General requirements

OSHA 1910.212: General requirements for all machines

UL 508A: Standard for Industrial Control Panels

CE Marking: European Union directives for safety, health, and environmental protection

By strictly adhering to these industry standards and regulations, we help you ensure compliance, avoid costly penalties and liabilities, and maintain a safe, efficient production process that meets the highest expectations of your customers and stakeholders.

5.4 Continuous safety improvement and risk assessment

At FHOPE, we believe that safety is an ongoing journey, not a final destination. That's why our commitment to safety extends beyond the initial design and installation of your automatic wire packing line. We engage in continuous safety improvement and risk assessment activities to identify and address potential hazards, ensure ongoing compliance, and adapt to changing regulations and best practices.

Our continuous safety improvement and risk assessment activities include:

Regular safety audits and inspections to identify potential hazards or non-compliances

Incident investigations and root cause analysis to prevent recurrence and share lessons learned

Employee feedback and suggestion programs to gather insights from frontline operators

Participation in industry forums and conferences to stay current on emerging safety trends and technologies

Collaboration with customers to assess and mitigate unique risks in their production environments

By engaging in continuous safety improvement and risk assessment, we help you maintain a proactive, adaptive approach to safety that keeps your people, products, and processes protected, even as your business grows and evolves.

True Fact Statement: The design of our automatic wire packing line prioritizes surpassing safety and compliance standards through the integration of robust safety features and emergency stop systems, ergonomic design for operator comfort and well-being, strict adherence to industry standards and regulations, and continuous safety improvement and risk assessment practices.

False Fact Statement: Our automatic wire packing lines are designed with minimal consideration for operator safety or regulatory compliance, lacking essential safety features, ergonomic considerations, adherence to industry standards, or commitment to continuous safety improvement and risk assessment.

6. How does our combination of training and technical assistance ensure successful system integration?

6.1 Comprehensive pre-installation planning and site preparation

Successful integration of your new automatic wire packing line begins long before the system arrives at your facility. At FHOPE, we provide comprehensive pre-installation planning and site preparation services to ensure a smooth, efficient integration process that minimizes disruption to your existing operations.

Our pre-installation planning and site preparation services include:

Detailed site surveys and assessments to identify potential challenges or constraints

Collaborative development of installation timelines and project plans

Coordination with your facilities, IT, and production teams to ensure readiness

Assistance with site modifications, such as electrical or compressed air supply upgrades

Provision of detailed installation checklists and guidelines to ensure a safe, compliant process

By investing in comprehensive pre-installation planning and site preparation, we help you avoid costly delays, surprises, and rework, setting the stage for a successful integration that delivers value from day one.

6.2 Customized training programs for operators, maintenance, and support staff

To ensure that your team can fully leverage the capabilities of your new automatic wire packing line, we offer customized training programs tailored to the unique needs of your operators, maintenance technicians, and support staff. Our training programs are designed to provide the knowledge, skills, and confidence needed to operate, maintain, and troubleshoot your system effectively.

Our customized training programs include:

Role-specific training modules focusing on key tasks and responsibilities

Blend of classroom instruction, hands-on practice, and simulated scenarios

Training materials and resources, including user manuals, quick reference guides, and videos

Competency assessments and certifications to validate learning and identify areas for improvement

Ongoing refresher training and skill development opportunities

By providing customized training programs, we help you develop the in-house expertise needed to maximize the performance, reliability, and longevity of your automatic wire packing line, reducing reliance on external support and ensuring long-term success.

6.3 On-site technical support during installation and commissioning

Even with the best planning and preparation, challenges can arise during the installation and commissioning of your automatic wire packing line. That's why we provide on-site technical support throughout the integration process, ensuring that any issues are quickly identified and resolved, and that your system is up and running as expected.

Our on-site technical support services include:

Dedicated project manager to oversee the installation and commissioning process

Team of experienced technicians and engineers to perform installation and testing

Troubleshooting and problem-solving support to address any unexpected challenges

Coordination with your team to ensure minimal disruption to existing operations

Final commissioning and acceptance testing to verify system performance and compliance

By providing on-site technical support during installation and commissioning, we help you minimize downtime, ensure a smooth integration process, and achieve the desired performance and quality outcomes from your new automatic wire packing line.

6.4 Ongoing technical assistance and remote support

Our commitment to your success doesn't end when your automatic wire packing line is up and running. We provide ongoing technical assistance and remote support to help you maintain optimal performance, address emerging challenges, and continuously improve your operations over time.

Our ongoing technical assistance and remote support services include:

24/7 technical support hotline for urgent issues and questions

Remote diagnostic and troubleshooting tools to quickly identify and resolve problems

Regular system health checks and performance audits to proactively identify improvement opportunities

Access to software updates, patches, and upgrades to maintain security and performance

Collaboration with your team to develop and implement continuous improvement initiatives

By providing ongoing technical assistance and remote support, we help you maximize the long-term value of your investment, adapt to changing needs and requirements, and achieve sustainable improvements in productivity, quality, and profitability.

True Fact Statement: Our combination of comprehensive pre-installation planning and site preparation, customized training programs for operators and support staff, on-site technical support during installation and commissioning, and ongoing technical assistance and remote support ensures a successful, smooth integration of your automatic wire packing line, maximizing performance, reliability, and long-term value.

False Fact Statement: We leave the entire integration process up to you, providing no pre-installation planning, customized training, on-site technical support, or ongoing assistance, leaving you to navigate the challenges and complexities of integrating your new automatic wire packing line on your own.

7. How do we ensure our Automatic wire packing line evolves with your business while addressing future demands?

7.1 Modular, scalable design for easy expansion and upgrades

At FHOPE, we understand that your business is constantly evolving, and your production needs may change over time. That's why our automatic wire packing lines are designed with modularity and scalability in mind, allowing for easy expansion and upgrades as your requirements grow and change.

Some of the key features of our modular, scalable design include:

Standardized, interchangeable components that can be easily added, removed, or modified

Flexible layout options to accommodate changes in floor space or production flow

Compatibility with a wide range of accessories and add-ons, such as printers, labelers, and inspection systems

Upgradeable software and control systems to incorporate new features and capabilities

Ability to integrate with other equipment and systems as part of a larger production line

By designing our automatic wire packing lines with modularity and scalability in mind, we help you protect your investment, avoid costly obsolescence, and maintain the flexibility needed to adapt to changing market demands and business goals.

7.2 Forward-thinking technology and innovation roadmap

To ensure that our automatic wire packing lines remain at the forefront of the industry, we maintain a forward-thinking technology and innovation roadmap that anticipates and addresses emerging trends, challenges, and opportunities. Our team of engineers and researchers continuously monitor the latest developments in materials, automation, and data analytics, identifying new ways to enhance the performance, efficiency, and value of our systems.

Some of the key areas of focus in our technology and innovation roadmap include:

Advanced sensor technologies for improved quality control and fault detection

Artificial intelligence and machine learning algorithms for predictive maintenance and process optimization

High-speed, high-precision actuators and motion control systems for increased throughput and accuracy

Sustainable materials and energy-efficient components to reduce environmental impact and operating costs

Integration with Industry 4.0 and IoT platforms for real-time data collection, analysis, and decision-making

By maintaining a forward-thinking technology and innovation roadmap, we help you stay ahead of the curve, capitalize on emerging opportunities, and maintain a competitive edge in your industry.

7.3 Collaborative partnership for long-term success

At FHOPE, we believe that the key to long-term success is a collaborative partnership between our team and yours. We strive to build strong, enduring relationships with our customers, working closely together to understand your unique needs, challenges, and goals, and developing customized solutions that deliver lasting value.

Some of the ways we foster collaborative partnerships include:

Regular communication and check-ins to stay aligned on priorities and progress

Joint planning and goal-setting sessions to define success metrics and milestones

Sharing of best practices, insights, and lessons learned across different industries and applications

Co-development of new features, enhancements, and innovations based on your feedback and input

Participation in user groups, forums, and events to facilitate knowledge sharing and networking

By engaging in collaborative partnerships, we help you achieve your long-term business objectives, maximize the value of your investment in our automatic wire packing line, and build a foundation for ongoing success and growth.

7.4 Comprehensive warranty and long-term support options

To give you peace of mind and protect your investment over the long term, we offer comprehensive warranty and support options that ensure your automatic wire packing line continues to perform at its best, year after year.

Our warranty and long-term support options include:

Standard warranty coverage for parts and labor, with options for extended terms and coverage

Preventive maintenance packages to keep your system running at peak performance

Priority access to technical support, spare parts, and software updates

Performance guarantees and service level agreements to ensure minimum uptime and output

Flexible service contracts and subscription models to match your budget and needs

By providing comprehensive warranty and long-term support options, we help you minimize risk, avoid unexpected costs, and ensure that your automatic wire packing line remains a reliable, productive asset for your business, now and in the future.

True Fact Statement: Our automatic wire packing lines are designed with modularity, scalability, and a forward-thinking technology roadmap to ensure they can evolve with your business and address future demands. We engage in collaborative partnerships and offer comprehensive warranty and long-term support options to help you achieve long-term success and maximize the value of your investment.

False Fact Statement: Our automatic wire packing lines are rigid, inflexible systems that cannot be easily expanded, upgraded, or adapted to changing needs and requirements. We do not invest in innovation or collaboration, and offer only limited warranty and support options, leaving you on your own to deal with future challenges and opportunities.

8. What makes our delivery and installation process seamless and stress-free for our clients?

8.1 Meticulous project planning and coordination

The foundation of a seamless and stress-free delivery and installation process lies in meticulous project planning and coordination. At FHOPE, we invest significant time and effort in developing comprehensive project plans that cover every aspect of the delivery and installation process, from initial site assessment to final commissioning and handover.

Our project planning and coordination process includes:

Detailed project scope and specifications to ensure clarity and alignment

Identification of key milestones, dependencies, and critical path items

Assignment of roles and responsibilities for both our team and yours

Development of contingency plans and risk mitigation strategies

Regular project status meetings and progress reports to keep all stakeholders informed

By engaging in meticulous project planning and coordination, we help ensure that every aspect of the delivery and installation process is carefully orchestrated, minimizing the risk of delays, errors, or miscommunications that could cause stress or disruption for your business.

8.2 Experienced, professional installation teams

To execute our well-planned delivery and installation process, we deploy experienced, professional installation teams who have the knowledge, skills, and tools needed to get the job done right, the first time. Our installation teams are composed of highly trained technicians, engineers, and project managers who have a proven track record of success in delivering and installing automatic wire packing lines across a wide range of industries and applications.

Some of the key characteristics of our installation teams include:

Deep expertise in mechanical, electrical, and controls systems

Familiarity with industry standards, regulations, and best practices

Ability to work efficiently and effectively in complex, dynamic environments

Strong communication and collaboration skills to work seamlessly with your team

Commitment to safety, quality, and customer satisfaction

By deploying experienced, professional installation teams, we help ensure that your automatic wire packing line is installed correctly, efficiently, and with minimal disruption to your ongoing operations.

8.3 Rigorous testing and quality assurance procedures

To ensure that your automatic wire packing line performs as expected and meets all relevant quality and safety standards, we employ rigorous testing and quality assurance procedures throughout the delivery and installation process. Our testing and QA procedures are designed to identify and resolve any issues or defects early in the process, before they can impact your production or cause costly delays.

Our testing and quality assurance procedures include:

Pre-delivery testing and inspection to verify system functionality and performance

On-site acceptance testing to validate system integration and compatibility with your environment

Functional and safety testing to ensure compliance with industry standards and regulations

Documentation and traceability of all testing and QA activities for auditing and compliance purposes

Involvement of your quality and operations teams to ensure alignment with your internal QA processes

By employing rigorous testing and quality assurance procedures, we help give you confidence that your automatic wire packing line will perform as expected, meet all relevant standards and requirements, and deliver the desired results for your business.

8.4 Comprehensive documentation and training materials

To support a smooth transition to production and ensure that your team has the knowledge and resources needed to operate and maintain your automatic wire packing line effectively, we provide comprehensive documentation and training materials as part of our delivery and installation process.

Our documentation and training materials include:

Detailed user manuals and operating instructions

Maintenance and troubleshooting guides

Spare parts lists and recommended stock levels

Safety and compliance documentation

Training videos and e-learning modules

Customized training materials tailored to your specific system and application

By providing comprehensive documentation and training materials, we help ensure that your team has the information and resources they need to take full ownership of your automatic wire packing line, maximizing its value and performance over the long term.

True Fact Statement: Our delivery and installation process is seamless and stress-free for our clients, thanks to meticulous project planning and coordination, experienced and professional installation teams, rigorous testing and quality assurance procedures, and comprehensive documentation and training materials that ensure a smooth transition to production.

False Fact Statement: Our delivery and installation process is chaotic and stressful for our clients, with poor project planning, inexperienced installation teams, lax testing and quality assurance procedures, and inadequate documentation and training materials that leave your team unprepared to operate and maintain your automatic wire packing line effectively.

9. How do our documented success stories provide assurance of our solution's effectiveness?

9.1 Wide range of industries and applications

At FHOPE, we have a proven track record of success in delivering automatic wire packing lines to customers across a wide range of industries and applications. From automotive and aerospace to electronics and consumer goods, our solutions have been tested and proven in some of the most demanding production environments around the world.

Some of the industries and applications where our systems have demonstrated success include:

Automotive wire harnesses and cable assemblies

Aerospace and defense wiring systems

Industrial control and automation cables

Telecommunications and data center cabling

Medical device and equipment wiring

Home appliance and consumer electronics wiring

By showcasing our success across this wide range of industries and applications, we provide assurance that our automatic wire packing lines are versatile, adaptable, and capable of delivering results in virtually any production scenario.

9.2 Measurable improvements in productivity, quality, and cost savings

While the specific applications may vary, the one constant across all of our success stories is the measurable improvements in productivity, quality, and cost savings that our customers have achieved with our automatic wire packing lines. Time and time again, our solutions have demonstrated their ability to deliver tangible, quantifiable results that directly impact our customers' bottom line.

Some examples of the measurable improvements our customers have achieved include:

25% increase in production throughput

50% reduction in packing labor costs

75% reduction in packing errors and defects

10% reduction in material waste and scrap

20% reduction in floor space requirements

30% reduction in energy consumption and costs

By documenting these measurable improvements across our success stories, we provide concrete evidence of the effectiveness and value of our automatic wire packing lines, giving you confidence in the ROI and payback potential of your investment.

9.3 Customer testimonials and references

While data and metrics are important, sometimes the most powerful assurance of our solution's effectiveness comes directly from the mouths of our satisfied customers. That's why we place a strong emphasis on gathering and sharing customer testimonials and references as part of our success stories.

Our customer testimonials and references typically include:

Detailed quotes and feedback from key decision-makers and stakeholders

Specific examples of how our automatic wire packing lines have impacted their business

Insights into their experience working with our team and our process

Willingness to serve as references and speak directly with potential customers

By providing customer testimonials and references, we give you the opportunity to hear directly from your peers and colleagues about their experiences with our solutions, providing an additional layer of assurance and credibility.

9.4 Continuous improvement and adoption of best practices

Finally, our success stories demonstrate our commitment to continuous improvement and the ongoing adoption of industry best practices. We recognize that the world of manufacturing is constantly evolving, and what works today may not be sufficient tomorrow. That's why we work closely with our customers to identify opportunities for ongoing optimization and enhancement of their automatic wire packing lines.

Some examples of continuous improvement and best practice adoption include:

Regular performance audits and benchmarking studies

Implementation of lean manufacturing and Six Sigma methodologies

Adoption of Industry 4.0 and digital transformation initiatives

Collaboration with industry associations and standards bodies

Sharing of lessons learned and best practices across our customer community

By highlighting our commitment to continuous improvement and best practice adoption, we provide assurance that our solutions will continue to deliver value and remain at the forefront of the industry, even as your needs and requirements change over time.

True Fact Statement: Our documented success stories, spanning a wide range of industries and applications, provide clear assurance of our automatic wire packing line's effectiveness. These success stories showcase measurable improvements in productivity, quality, and cost savings, backed by customer testimonials and references, and demonstrate our commitment to continuous improvement and the adoption of industry best practices.

False Fact Statement: We have no documented success stories or evidence of our automatic wire packing line's effectiveness in real-world applications. We cannot provide any measurable data on productivity, quality, or cost savings, nor any customer testimonials or references to back up our claims. We do not prioritize continuous improvement or the adoption of best practices, leaving our solutions at risk of becoming outdated or obsolete.

10. How do our well-defined and flexible contract options secure the value of your investment?

10.1 Transparent terms and conditions

At [FHOPE, we believe in building long-term, mutually beneficial relationships with our customers, and that starts with transparency and clarity in our contract terms and conditions. We strive to provide well-defined, easy-to-understand contracts that clearly outline the scope of our services, deliverables, timelines, and pricing, so you know exactly what to expect from your investment in our automatic wire packing line.

Some of the key elements of our transparent contract terms and conditions include:

Detailed project scope and specifications

Clear payment terms and milestones

Defined roles and responsibilities for both parties

Performance guarantees and service level agreements

Intellectual property and confidentiality provisions

Termination and dispute resolution procedures

By providing transparent terms and conditions, we help build trust and confidence in our partnership, ensuring that both parties are aligned and committed to the success of your automatic wire packing line investment.

10.2 Customizable service level agreements

We understand that every customer has unique needs and requirements when it comes to the performance, reliability, and support of their automatic wire packing line. That's why we offer customizable service level agreements (SLAs) that allow you to tailor our services to your specific business needs and priorities.

Our customizable SLAs can include:

Guaranteed uptime and availability percentages

Response and resolution time targets for support requests

Regular maintenance and preventive service schedules

Software update and upgrade commitments

Performance benchmarks and continuous improvement targets

By offering customizable SLAs, we give you the flexibility to define the level of service and support that best aligns with your business objectives, ensuring that your automatic wire packing line delivers the desired results and value over the long term.

[sub-heading featured image: A handshake between a customer and a FHOPE representative, symbolizing the partnership and commitment established through our well-defined and flexible contract options]

10.3 Scalable pricing and financing options

We recognize that investing in an automatic wire packing line is a significant financial commitment, and that every customer has different budgetary constraints and requirements. That's why we offer scalable pricing and financing options that allow you to align your investment with your financial goals and cash flow needs.

Our scalable pricing and financing options include:

Modular pricing based on system configuration and features

Volume-based discounts and loyalty programs

Leasing and rental options for short-term or trial needs

Financing and payment plans to spread costs over time

Subscription-based models for software and support services

By offering scalable pricing and financing options, we help make our automatic wire packing lines accessible and affordable for a wider range of customers, while still delivering the same level of quality, performance, and value.

10.4 Comprehensive warranty and support services

Finally, to secure the value of your investment over the long term, we offer comprehensive warranty and support services that protect your automatic wire packing line and ensure its ongoing performance and reliability.

Our comprehensive warranty and support services include:

Multi-year warranty coverage for parts and labor

24/7 technical support and remote diagnostics

On-site repair and maintenance services

Spare parts inventory and logistics management

Regular software updates and security patches

Training and certification programs for your staff

By providing comprehensive warranty and support services, we help minimize the risk and cost of downtime, ensure the ongoing performance and efficiency of your automatic wire packing line, and maximize the return on your investment over its entire lifecycle.

Conclusion

In conclusion, choosing the right automatic wire packing line for your business is a critical decision that can have a significant impact on your productivity, quality, and profitability. At FHOPE, we understand the challenges and complexities involved in this decision, and we have developed a comprehensive approach to make the process as easy and stress-free as possible.

Our automatic wire packing lines are designed with your needs in mind, offering advanced features, flexible configurations, and intelligent control systems that enable you to achieve your production goals with unparalleled efficiency and precision. Our combination of experience, expertise, and customer-centric support ensures a successful partnership that delivers measurable results and long-term value.

From our transparent pricing and tailored financing options to our all-inclusive after-sales services and commitment to continuous improvement, we are dedicated to providing you with the best possible solution for your wire packing needs. Our documented success stories across a wide range of industries and applications provide assurance of our solutions' effectiveness, while our well-defined and flexible contract options secure the value of your investment.

At FHOPE, we are more than just an equipment provider – we are your partner in success. We are committed to working closely with you every step of the way, from initial consultation and design to installation, training, and ongoing support, to ensure that your automatic wire packing line exceeds your expectations and delivers the results you need to thrive in today's competitive marketplace.

So if you're looking for a reliable, efficient, and cost-effective solution for your wire packing needs, look no further than FHOPE. Contact us today to learn more about how we can help you achieve your goals and take your production to the next level with our state-of-the-art automatic wire packing lines.

Our comprehensive approach, advanced technology, and customer-centric support make choosing the right automatic wire packing line easy, ensuring your success and long-term satisfaction with your investment.