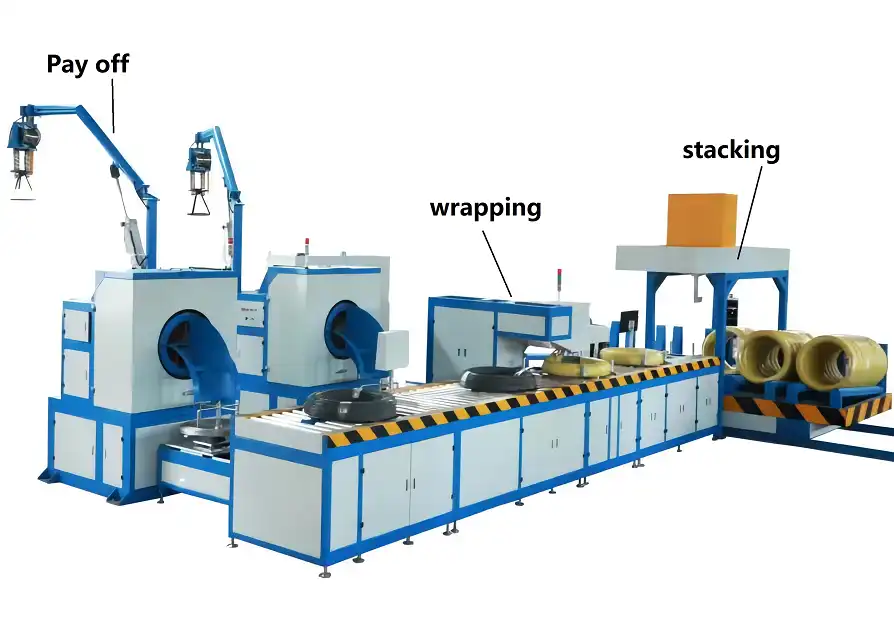

Steel wire winding and wrapping machine

The Full-Automatic Wire Packaging Line is an advanced off-line solution designed to streamline wire coil handling and packaging. Equipped with cutting-edge automation, it ensures precise coil making, strapping, and stacking, enhancing efficiency and accuracy while reducing manual labor.

Key Features

PLC & HMI Control: Fully automated operation with multi-language support (English/Chinese).

Automatic Coil Making: Precisely measures and coils wire to specified lengths.

Strapping System: PET/PP straps with 2-4 strapping points for secure packaging.

Power Conveyors: Automatically move coils to the wrapping machine.

Turnover & Stacking System: Safely unloads and arranges finished coils for transport.

Optional Add-ons: Weighing system, automatic labeling, and customized configurations.

Special Features

Related video

A steel wire winding and wrapping machine is a specialized industrial equipment designed to coil and securely wrap steel wires. It ensures precision, consistency, and protection during storage or transportation. Ideal for steel processing and manufacturing industries, it enhances efficiency, reduces labor, and maintains the quality of wound steel wires.

Full-Automatic Wire Packaging Line: Revolutionizing Coil Packaging Processes

The Full-Automatic Wire Packaging Line is an advanced off-line system designed to automate the handling, coiling, strapping, and packaging of wire products. This innovative solution significantly improves efficiency, accuracy, and product handling, making it an indispensable tool for modern wire manufacturing operations.

With its robust features, including automated coiling, strapping, stacking, and labeling, the packaging line ensures seamless and error-free operations. Its use of PLC and HMI control systems provides full customization and monitoring capabilities for enhanced productivity and reduced labor costs.

Core Features and Capabilities

1. PLC and HMI Control Program

Fully automated operation with easy-to-use controls.

Parameters can be set in English or Chinese, ensuring user-friendly interaction.

Customizable settings for coil lengths, strapping patterns, and operational modes.

2. Automatic Coil Making

Precise Length Counting: Automatically measures and coils wires to the specified lengths.

Eliminates manual errors, ensuring uniformity and consistency.

3. Automatic Strapping System

Utilizes PET/PP straps for securing coils, with options for 2 or 4 straps per coil.

Ensures coils are tightly bound, reducing risks during transport and storage.

4. Power Conveyor Integration

Coils are automatically transported one by one into the wrapper machine for efficient packaging.

Reduces manual handling and speeds up the process.

5. Advanced Stacking System

Features a hook mechanism for precise coil movement:

Moves coils up, down, left, and right from the conveyor to a discharging trolley.

Ensures organized stacking and easy unloading.

6. Additional Optional Features

Weighing System: Adds weight measurement capabilities within the packaging line.

Automatic Labeling Machine: Integrates after the wrapper machine for product labeling.

Turnover Equipment: Holds and unloads finished coils one by one for streamlined operations.

Automatic Trolley System: Stacks and arranges coils for outgoing loading.

Benefits of the Full-Automatic Wire Packaging Line

Enhanced Efficiency

Automates repetitive tasks, reducing reliance on manual labor.

Integrates seamlessly with existing workflows, ensuring continuous operations.

Improved Accuracy

Precise coiling and strapping eliminate inconsistencies and errors.

Automated stacking and labeling enhance product handling and traceability.

Cost-Effectiveness

Reduces labor costs and minimizes material waste.

High-speed operations increase throughput, boosting overall productivity.

Safety and Reliability

Designed with well-known branded components for durability and performance.

Adheres to strict safety protocols, ensuring secure and reliable operation.

Applications

This full-automatic packaging line is ideal for manufacturers in industries such as:

Steel Wire Production

Cable Manufacturing

Metal Coil Handling

Industrial Packaging Solutions

Key Considerations for Safe and Reliable Operation

Regular Maintenance:

Perform routine checks on critical components like conveyors, strapping devices, and stacking systems to ensure smooth operations.

Proper Safety Protocols:

Follow operational guidelines and ensure workers are trained to handle machinery safely.

Use of Quality Materials:

Employ recommended materials like PET/PP straps and well-branded components to maintain optimal performance.

Why Choose This Packaging Line?

Comprehensive Automation: Handles the entire process from coiling to stacking.

Customizable Features: Tailored options to meet diverse production needs.

Reliability and Durability: Engineered with high-quality components for long-term use.

Global Usability: Multi-language controls and adaptable design for international operations.

The Full-Automatic Wire Packaging Line is the future of wire packaging, providing unparalleled efficiency, accuracy, and reliability. By investing in this advanced system, manufacturers can significantly enhance their production capabilities, reduce operational costs, and maintain consistent quality across their products.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635