Steel Coil Packing Line for Industrial Manufacturing: Technical Specification and ROI Analysis

Market Context: Steel Processing in Modern Service Centers

Global steel service centers processing 500-5000 tons monthly face three recurring technical challenges: inconsistent wrapping tension (±15% deviation), material waste averaging 18-22% per shift, and processing bottlenecks limiting throughput to 8-12 coils/hour in manual configurations.

Technical Challenges in Steel Service Centers

1. Manual Packaging Limitations

Manual steel coil packing line operations in typical facilities report:

- Average cycle time: 25-30 minutes per coil (ID 508-762mm)

- Material consumption: 2.8-3.5 kg stretch film per ton of steel

- Labor requirement: 3-4 operators per packaging station

- Damage rate during transit: 4-7% due to insufficient protection

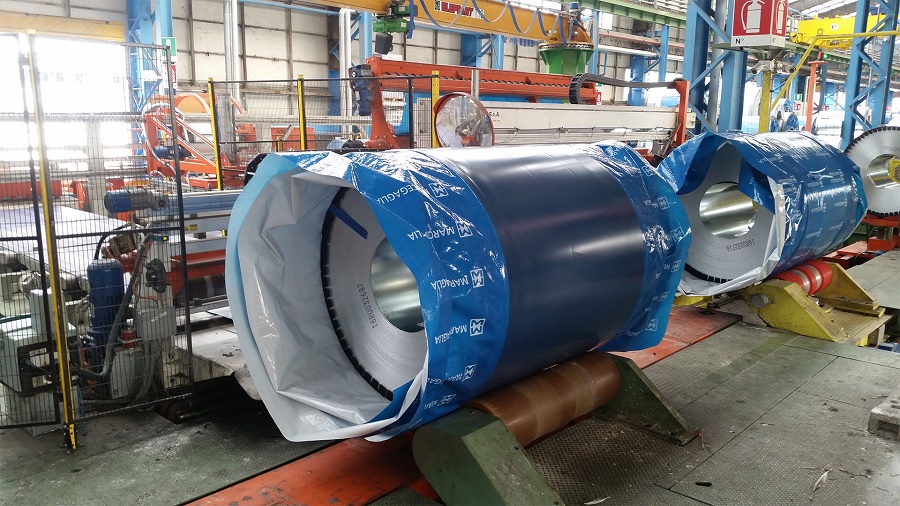

2. Environmental Protection Requirements

Industrial regions with humidity levels exceeding 65-85% demand corrosion-resistant packaging. Standard VCI film applications show 30% failure rate after 45-day storage in non-climate-controlled environments across coastal and tropical zones.

Automatic Coil Packaging Line Manufacturer Solution

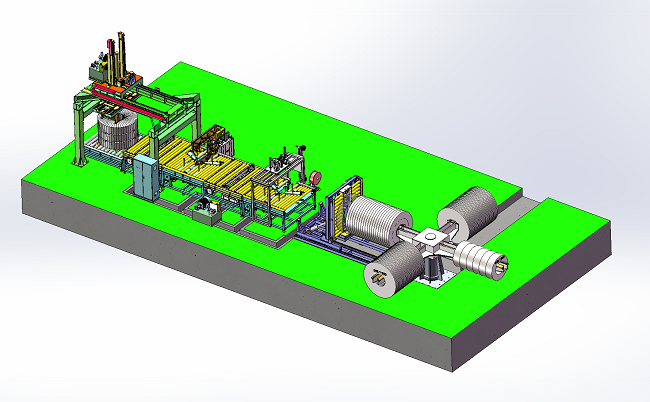

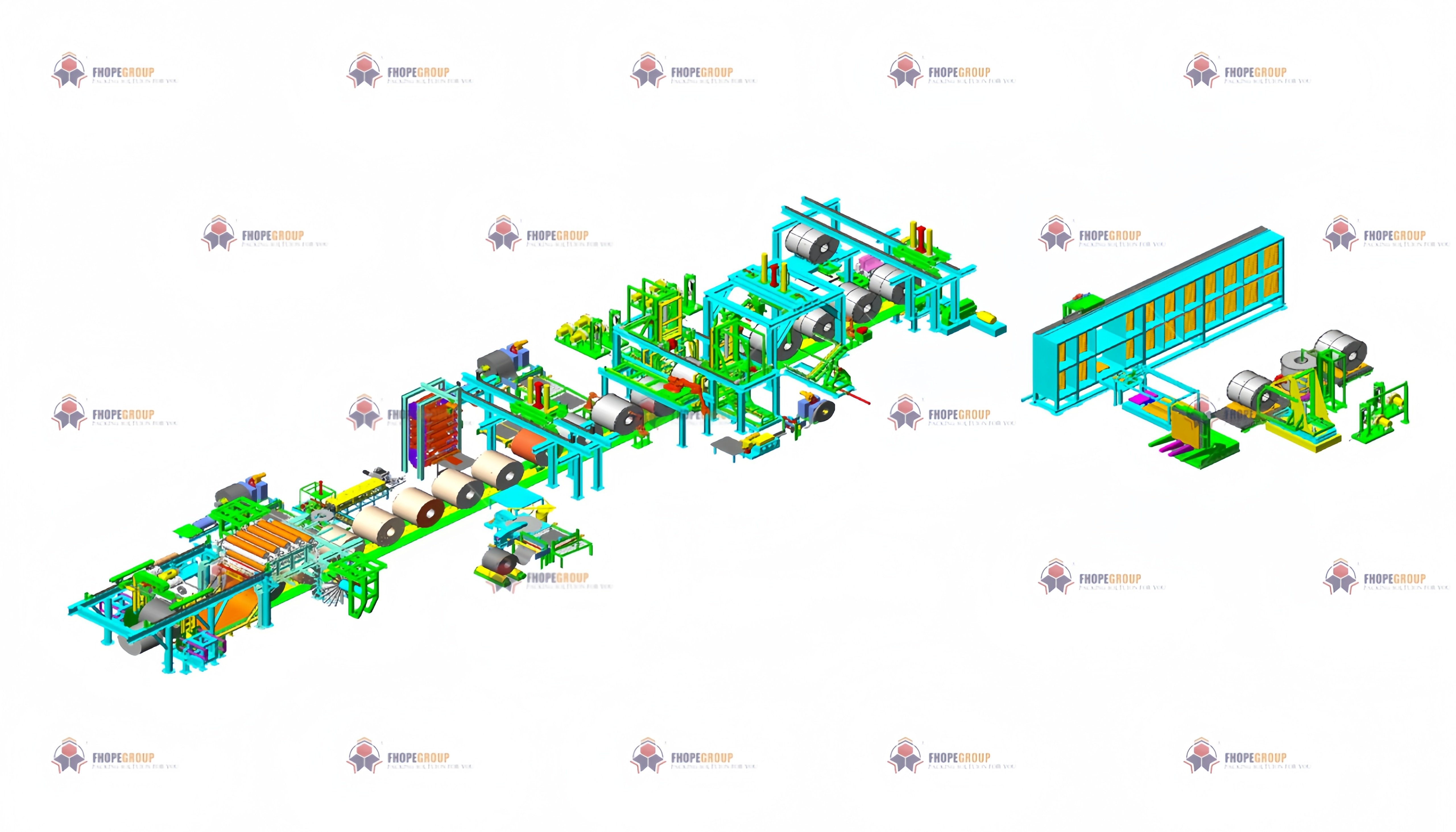

System Architecture

Our steel coil packing line integrates four functional modules:

- Coil feeding system: Hydraulic lift capacity 500-5000 kg, positioning accuracy ±5mm

- Wrapping mechanism: Orbital rotation 8-15 rpm, adjustable overlap 40-60%

- Material application unit: Compatible with stretch film (50-500μm), VCI paper, HDPE woven fabric

Discharge conveyor: Variable speed 2-12 m/min

Technical Specifications

| Parameter | Standard Configuration | Heavy-Duty Option |

|---|---|---|

| Coil OD range | 400-1600 mm | 800-2200 mm |

| Coil ID range | 508-762 mm | 508-850 mm |

| Maximum weight | 3000 kg | 5000 kg |

| Wrapping speed | 20-35 coils/hour | 15-25 coils/hour |

| Power consumption | 18.5 kW | 28 kW |

| Compressed air | 0.6-0.8 MPa, 120 L/min | 0.8 MPa, 180 L/min |

| Film carriage capacity | 4 stations × 300mm width | 6 stations × 500mm width |

| PLC system | Siemens S7-1200 | Siemens S7-1500 |

Performance Comparison: Manual vs. Automatic System

| Metric | Manual Operation | Automatic Coil Packaging Line | Improvement |

|---|---|---|---|

| Throughput (coils/8h) | 64-72 | 160-280 | +125-289% |

| Film consumption (kg/ton) | 2.8-3.5 | 1.6-2.1 | -40-43% |

| Labor requirement | 3-4 operators | 1 operator + supervisor | -67-75% |

| Setup time per coil | 8-12 min | 1.5-2.5 min | -79-83% |

| Wrapping consistency (CV) | 18-25% | 3-5% | Standard deviation reduction |

| Energy cost per coil | N/A | $0.42-0.75 (regional rate) | Measurable baseline |

ROI Calculation for Industrial Operations

Investment Structure

Base system cost: $125,000-165,000 FOB (depending on configuration)

Shipping to destination port: $3,800-6,500 (distance-dependent)

Installation and commissioning: $6,500

Operator training (40 hours): $2,000

Total landed cost: $137,300-180,000

Annual Operating Cost Reduction

Based on 220 working days, 2-shift operation (3,520 operating hours/year):

- Labor savings: 2.5 operators × $18,000/year = $45,000

- Material efficiency: 150 coils/day × 1.8 kg saved × $2.2/kg × 220 days = $130,680

- Reduced damage claims: 5% damage rate × 33,000 coils/year × $85 average claim = $140,250

- Energy offset: $8,500/year (compared to extended manual operation lighting/HVAC)

Total annual benefit: $324,430

Simple payback period: 5.1-6.6 months

3-year NPV (8% discount rate): $687,000-721,000

Installation Timeline for International Projects

| Phase | Duration | Requirements |

|---|---|---|

| Pre-shipment engineering review | 5-7 days | Floor plan, power specs, compressed air capacity |

| International shipping | 25-45 days | Route-dependent (Asia-Europe 28-35d, Asia-Americas 30-45d) |

| Customs clearance | 3-7 days | HS code 8422.30, duty varies by region |

| Local transport to facility | 1-3 days | Oversize load permit if required |

| Mechanical installation | 4-5 days | Concrete foundation (if specified) |

| Electrical/pneumatic integration | 2-3 days | 380-480V 3-phase connection |

| Commissioning and testing | 2 days | 50-coil trial run |

| Operator certification | 3 days | Hands-on training, safety protocols |

Total project duration: 45-73 days from PO to production start

Maintenance Requirements

- Preventive maintenance interval: Every 2,000 operating hours

- Consumable parts: Film cutting blades (every 8,000 coils), conveyor rollers (annual inspection)

- Spare parts inventory value: $8,500-12,000 (recommended 18-month supply)

- Local service availability: 48-72 hour response time via regional service network

FAQ: Technical Specifications

Q: Can the system handle hot-rolled coil surface variations (scale, oil residue)?

A: Yes. Film pre-stretch ratio adjustable 200-280% compensates for surface irregularities. Optional degreasing station available.

Q: Integration with existing ERP systems (SAP, Oracle)?

A: OPC UA protocol standard. Modbus TCP optional. Real-time data: coil ID, wrap count, film consumption, cycle time.

Q: Power supply compatibility with regional electrical standards?

A: Designed for 380-480V ±10%, 50/60Hz. Voltage stabilizer included for areas with >8% fluctuation. Compatible with IEC and NEMA standards.

Q: Compliance with international safety standards?

A: Full compliance. Emergency stop circuits, light curtains (Category 3, PLd), lockout/tagout provisions. Meets CE, OSHA, and ISO 12100 requirements. Documentation available in multiple languages.

Q: Film material sourcing flexibility?

A: Compatible with global film suppliers. Accepts standard 76mm and 152mm film cores. Support for regional material specifications.

Technical Support for Global Operations

- Remote diagnostics: 24/7 via VPN connection

- On-site service: Quarterly preventive maintenance available through authorized regional distributors

- Spare parts network: Regional distribution centers (24-72 hour delivery depending on location)

- Technical documentation: Multilingual manuals, wiring diagrams, PLC program backups (English, Spanish, German, Chinese)

Specification Request Process

To receive detailed engineering drawings and project quotation:

- Provide coil size range (OD, ID, width, weight)

- Production volume (coils/day, annual tonnage)

- Facility layout (AutoCAD/PDF preferred)

- Packaging material preference (film type, thickness, protection level)

- Integration requirements (existing conveyor systems, WMS)

Contact: Technical sales team responds within 24 hours with preliminary system configuration and budgetary pricing.

Engineering Data Sheet Download: Request complete specification package including electrical schematics, foundation requirements, and compressed air calculations for automatic coil packaging line manufacturer systems configured for global steel service center applications.