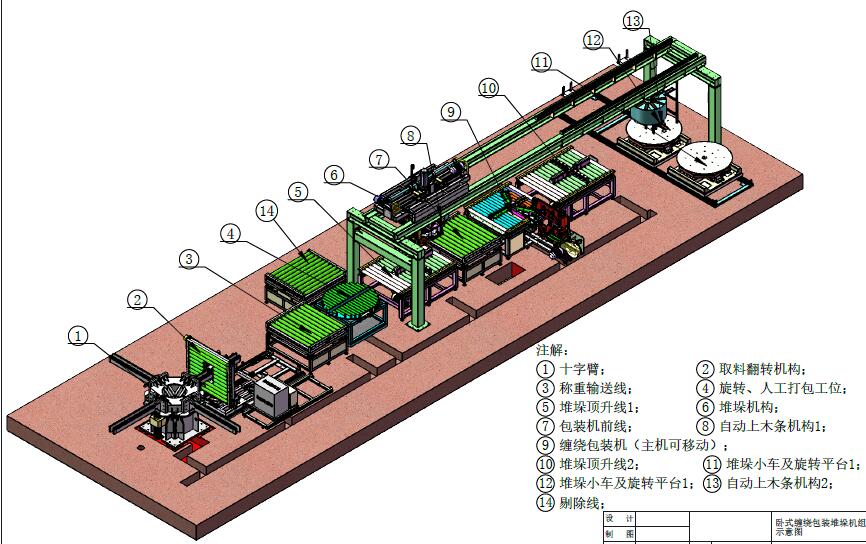

Automated Steel Coil Packaging line

The Automated Steel Coil Packaging Line is a new system designed for the seamless connecting with slitting line for coil handling, wrapping, and strapping of steel coils. Integrating advanced PLC controls, conveyors, and strapping stations, it optimizes packing processes with unmatched speed and consistency. This solution minimizes manual labor, enhances safety, and protects steel coils during transit and storage.

Key Parameters:

Coil Dimensions: OD 700–1600 mm, ID 508-610 mm, Width 20–500 mm

Weight Capacity: 100–5000 kg per coil

Packing Speed: 20–40 coils/hour

Power Supply: 380V, 3-phase, 50 Hz (can be customizied)

Automation: PLC and SCADA-based operation for precision control

特殊功能

Enhanced Production Efficiency

Significantly boosts packaging speed and reduces human errors, making it ideal for large-scale production.

Reduced Operational Costs

Lowers labor costs and minimizes material waste, offering substantial long-term cost savings.

Consistency and High Quality

Ensures standardized and high-quality packaging, enhancing customer trust and satisfaction.

相关视频

The Steel Coil Packaging Line is an industrial solution tailored to efficiently package steel coils with precision and safety. This automated system handles strapping, wrapping, and securing coils, reducing labor costs and safeguarding products during transport. It’s an ideal choice for high-volume operations seeking reliability and protection for their steel products.

FHOPE team can achieve your ideal packaging solution according to your packaging requirements.

Automated Steel Coil Packaging Line Parameters

| Function | Description |

|---|---|

| Automatic Steel Strips Cross Arms Stacking | Automatically stacks steel strips in cross arm configurations for efficient handling. |

| Coil Turning Over | Automated equipment for flipping coils to the required orientation. |

| Strapping | Applies durable straps to secure coils for transportation and storage. |

| Wrapping Packaging | Wraps coils with protective materials to prevent damage during shipping. |

| Auto Coils Conveying | Conveys coils automatically between different stages of the packaging process. |

| Coils Stacking | Stacks packaged coils systematically for storage or further processing. |

| Terminal Pallet Packaging | Packages the coils along with pallets for stability during shipping. |

快速为您的项目获取报价!

我们想和你一起工作

如果您有顾虑和具体要求,请与我们的行业专家交谈。他/她将支持你从计划到运输。

- +8613951501635

- info@fhopepack.com

- +8613951501635