Automatic pipe coiler

Automatic hose and pipe coiler and strapping machine line manufacutrer in China helps you find the automation solution after extruding machine with good price. Not man required for coiling process anymore...

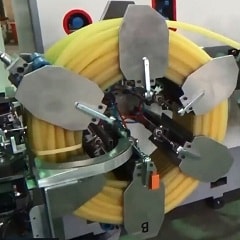

The automatic coiler was designed to coil a pipe into a ribbon coil. Operators ensure smooth and reliable transfer. The pipe coil is safely unloaded from the front side of the machine for operator use. Open the unload door while protecting the operator from the winding side of the machine. Automatically eject the coil onto an available trolley or receiving table.

Ask For a Quick Quote

The first 3 people who consult today will receive a free consumable parts package.

Automatic pipe coiler

Automatic pipe winding and packaging machine

Our FHOPE GROUP is committed to providing a comprehensive packaging solution for your production. It can provide a fully automatic winding and bundling function machine.

Automatic coiler FCL-H300

The automatic cable packaging line is for offline cable packaging. It is able counting the lengths of cable, automatic cutting, coil making, strapping with PP automatic shrinks or wrapping by film.

Automatic coiler FCL-H1000

This automatic winder is designed to wind a pipe into a ribbon coil. The dancers ensure a smooth and reliable transfer. The tube coil is safely removed from the front side of the machine for operator convenience.

Automatic Coiling Machine FCL-Y1200

Automatic Coiling and Strapping Machine for hdpe pipe

Automatic coiler FCL-Y800

HDPE pipe, PERT pipe, PEX pipe coiling and strapping online.Be used for high speed coiling the pipe online with extruding machine.

Automatic hose coiler FCL-V600

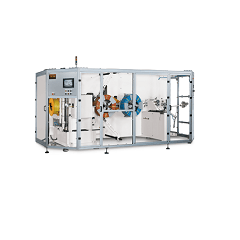

The automatic winding machine FCL-600 system is a vertical automatic winding machine. It is a complete line that can automate a series of complete steps from fixed length.

Automatic pipe coiler FCL-V800

The automatic winder FCL-800 is a complete line that automatically completes a series of complete steps from fixed length, then winding, cutting, bundling and winding to the final step of the production line.

Automatic coiler FCL-V1000

Automatic winders and strapping machines: automatic packaging lines for hoses and pipes. Coiler features: PLC and HMI control system for automatic operation.

Automatic winder FCL-V1200

Automatic winder and strapping machine Coiler features: PLC and HMI control system for automatic operation. Two working modes: automatic and manual.

Automatic winder FCL-V1600

This is a large automatic winder for large pipe winding and bundling, an automated packaging solution for increased automation. It consists of a hose winding and strapping system for continuous packaging.

Automatic winder FCL-S1000

This is an automatic reel and film wrapper for vertical winding and bundling, such as tube coils, hose rolls, etc. After coiling and bundling, the tube coils are well shaped.

Automatic winder FCL-S1600

This is an automatic winder and strapping machine for vertical winding and bundling, such as tube coils, hose coils, etc. After coiling and bundling, the tube coils are well shaped.

Automatic pipe winding and binding integrated packaging machine-Horizontal

Our FHOPE GROUP is committed to providing a comprehensive packaging solution for your production. It can provide a fully automatic winding and bundling function machine.

Automatic winding machine FCL-H600

The unloading door is opened while protecting the operator from the winding side of the machine. Automatically coil ejection onto a trolley or reception table available.

Automatic coiler FCL-H800

Switching Cabinets The electrical devices are installed on mounting plates in closed cabinets, protection degree IP20, designed in form 1 based on EN 60439-1.

Automatic winder and strapping machine FCL-V400

Description: This is a vertical automatic winder for corrugated hose winding. It is an all-in-one device that automates a series of complete steps, starting with a fixed length, then winding, cutting, bundling, winding, and more. It takes up a lot of space, but it can do the task of automatic winding and packaging efficiently and quickly, fully meeting the high standards of packaging. Function: Au

Packaging Cases

We have exported to more than 50 countries. Powerful service internet and install team makes us build relationships with customers who come from European, Middle East, South America, South East Asia.

Get The Best Solutions for Your Building!

Why Choose Us

Superior design, uncompromising quality and a growing list of satisfied customers have made Fhope a pioneer in the industry. All main core parts with EN81-20 and 50 certificate

15+ years experience

With 15+ years experience in the packaging machinery industry, with deep understanding of the specific needs of various industries, including steel, automotive, and construction materials.

Professional Technical Team

10 mechanical engineer, 8 electrical engineer, 4 service engineer, with 15 high skill technician ensure the precise and innovative solutions.

OEM And ODM Design

With Excellent Technology and Advanced design, to make the machine in semiauto or automated matches to your packaging goal 100%

24/7 after services

We offer top-notch after-sales services including on-site installation, training, and maintenance support. Our dedicated team ensures minimal downtime and fast issue resolution to keep your production line efficient.

Top Cost performance

Engineered for Efficiency and Longevity. Benefit from our high cost performance machine with comprehensive support, including expert installation, thorough training, and responsive maintenance.

Global Standard

With installations in multiple countries, we have a global presence but also understand the specific requirements and regulations of regional markets. This allows us to offer localized support while maintaining high global standards.

Frequently Asked Questions

Here are the most common questions about packing machines. If you can’t find what you need, call us on +8613951501635 or get in touch at info@fhopepack.com.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635