Cold Roll Steel Coil Strapping & Packing Line Manufacturer

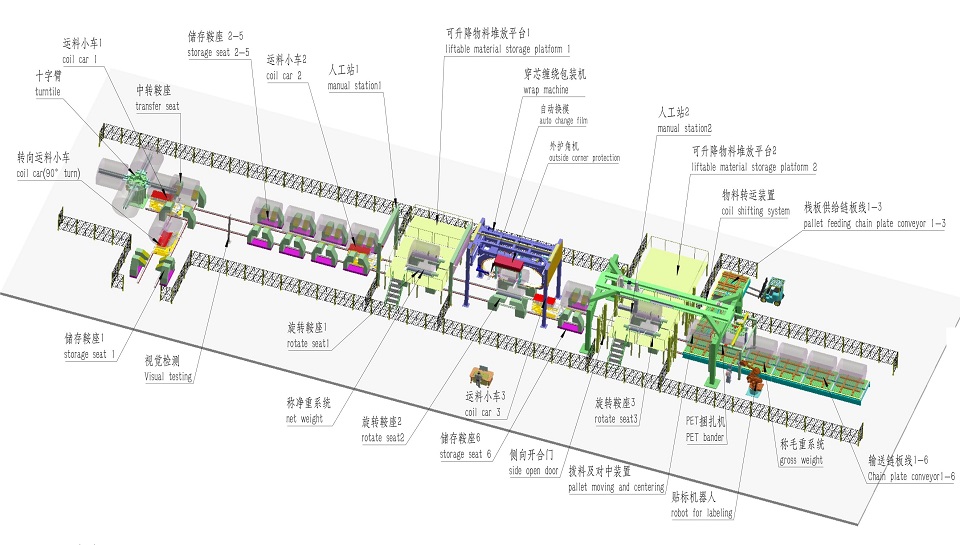

Equipment Overview:

The packaging line for cold roll steel coils will be fully automatic, integrating the latest proven technology for design, automation, and energy optimization. The equipment, provided by FHOPE, will ensure minimal personnel intervention and seamless operation with the production line and Automatic Storage and Retrieval System (ASRS).Key Features:

Fully automatic operation.

Energy-efficient and state-of-the-art technology.

Close integration with the cold roll production line and ASRS.

特殊功能

Enhanced Production Efficiency

Significantly boosts packaging speed and reduces human errors, making it ideal for large-scale production.

Reduced Operational Costs

Lowers labor costs and minimizes material waste, offering substantial long-term cost savings.

Consistency and High Quality

Ensures standardized and high-quality packaging, enhancing customer trust and satisfaction.

相关视频

A Cold Roll Steel Coil Strapping & Packing Line Manufacturer specializes in efficient, durable strapping and packaging solutions for steel coils. Leveraging advanced technology and robust materials, their equipment ensures coil safety during transport and storage, minimizes damage risks, and boosts operational efficiency for steel manufacturers.

Cold Roll Steel Coil Strapping & Packing Line Manufacturer

This specification outlines is the equipment requirements of the Col roll steel coil Packaging Line for automation project. FHOPE will providing the on site installation and technical service.As a manufacturer, the packaging machines shall be complete except for equipment noted as ‘Supplied by Others’ in this specification. The latest proven state-of-the-art technology in the design, automation, and component selection shall be used for this equipment. Equipment shall be energy optimized wherever possible. The line is intended to be fully automatic and or minimizing where possible to intervention of personnel. The Packaging line shall be close coupled to the production line. And the system provides transport method of coils from the cold roll production line and from the Automatic Storage and Retrieval System (ASRS) to the Packaging line.

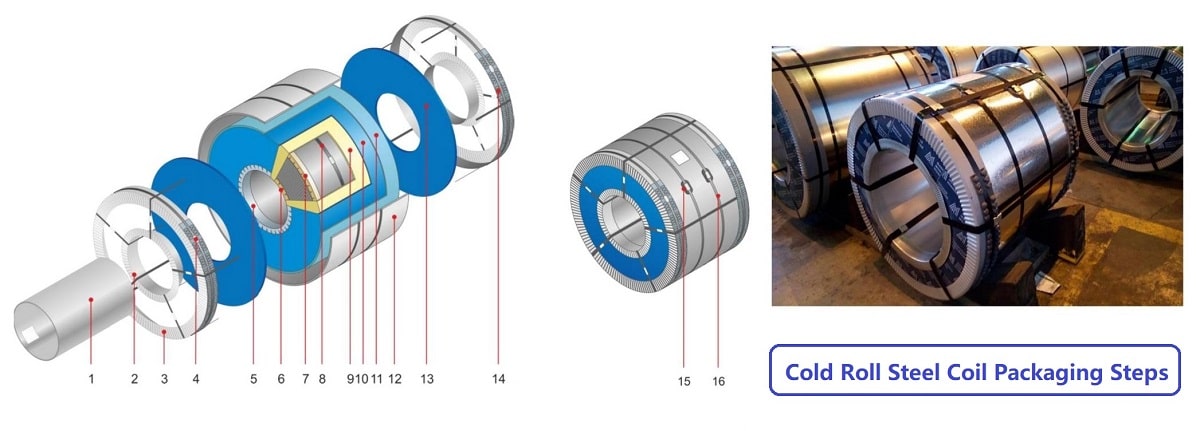

The typical packaging way of the cold roll steel coil packaging

2. ID steel edge protector

3. OD steel edge protector

4. OD edge protector strapping

5. ID cardboard protector

7. OD cardboard protector

8. Cold roll steel coil OD strapping

9. VCI paper covering

10. VCI film stretch wrapping

11. Cardboard OD covering

12. Steel sheet OD covering

13. Side cover

14. OD Edge protector

15. Cercumferece coil strapping

16. Radial coil strapping

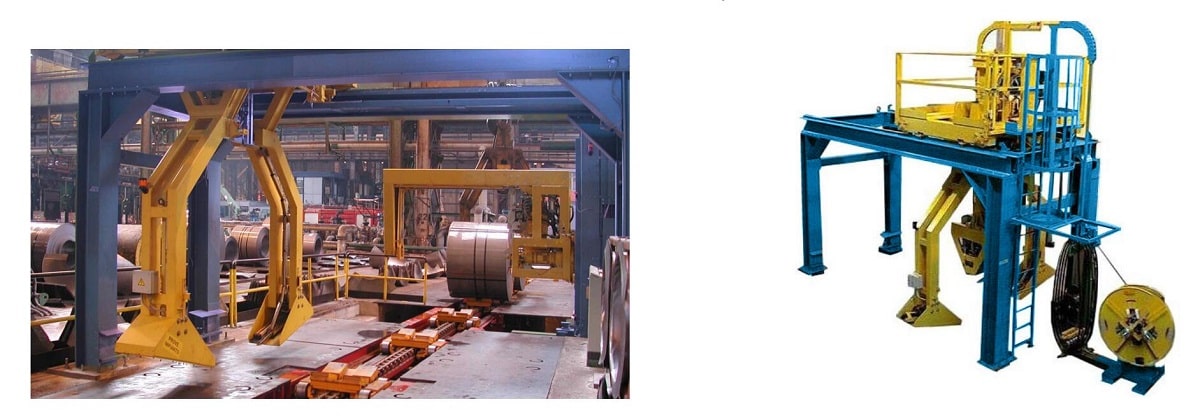

Circumferential strapping machine

Radial coil strapping machine

The radial coil strapping machine is able forward and backward by the rolley-mounted mobile base for automatic radial coil strapping

The rotation orbital mechanism and belt dispenser system is for automaitc position adjustment for checking the coil hole for eye throught steel belt feeding and strapping.

Parameters:

| Machine Weight | 6500kg | |||||

| Power Supply | AC 400V/50Hz | |||||

| Power consumpation | 15kw | |||||

| Operating pressure | 0.6mpa | |||||

| Air Consumption | 500 Nl / cycle | |||||

| Strapping speed | 20s per belt | |||||

The automatic packing line equipment required to package the steel coils shall be determined by the SELLER. The automatic system would be designed to handle, transport and

process material from the coil production line. Apply the necessary packaging materials and make ready final packages to be removed from the line by the BUYER.

Below is general expectation of the line provision:

1. Entry coil receiving and separator retainment equipment from productionline

2. Entry coil receiving from coil storage bay.

3. Weigh scale with label applicator magazine and printer systems integration.

4. Coil ID and OD scanner (for input into coil wrapping system)

5. Installation of inner ID edge protector. (automation as option)

6. Installation of steel belt strapping machien for banding through ID (3 each). (automation as option)

7. Automated installation of banding around OD (≥4).

8. Automated installation of outer OD edge protection.

9. Automated through the eye wrapping of coils ( x3 wrap layers) with twin

film wrapping shuttle to apply different film types simultaneously, with

automatic film shuttle exchange unit, and film cutter clamp with heat seal.

10. Adjustable film pre-stretch capability up to 50%

11. Installation of plastic side wall protectors. (automation as option)

12. Installation of plastic outer wrap protector (full coverage or partial

coverage). (automation as option)

13. Installation of radial coil strapping bands through ID (x 2). (automation as option)

14. Pallet handling and placement/centering equipment. (automation as option)

15. Automatic coil loading on pallet.

16. Installation of cercumference coil strapping bands around OD (≥4) (bands coil to pallet) (automation

as option)

17. Installation of label (x2 - 1 End sidewall + 1 OD) (automation as option)

18. Exit Queue equipment ( up to 4 palletized coils)

19. Fully integrated Packaging Line Control System

20. Machine Platforms and Stairs

21. Machine Safety Guarding Package

22. Perimeter Guarding

Master Coil Stretch Wrapper

快速为您的项目获取报价!

我们想和你一起工作

如果您有顾虑和具体要求,请与我们的行业专家交谈。他/她将支持你从计划到运输。

- +8613951501635

- info@fhopepack.com

- +8613951501635