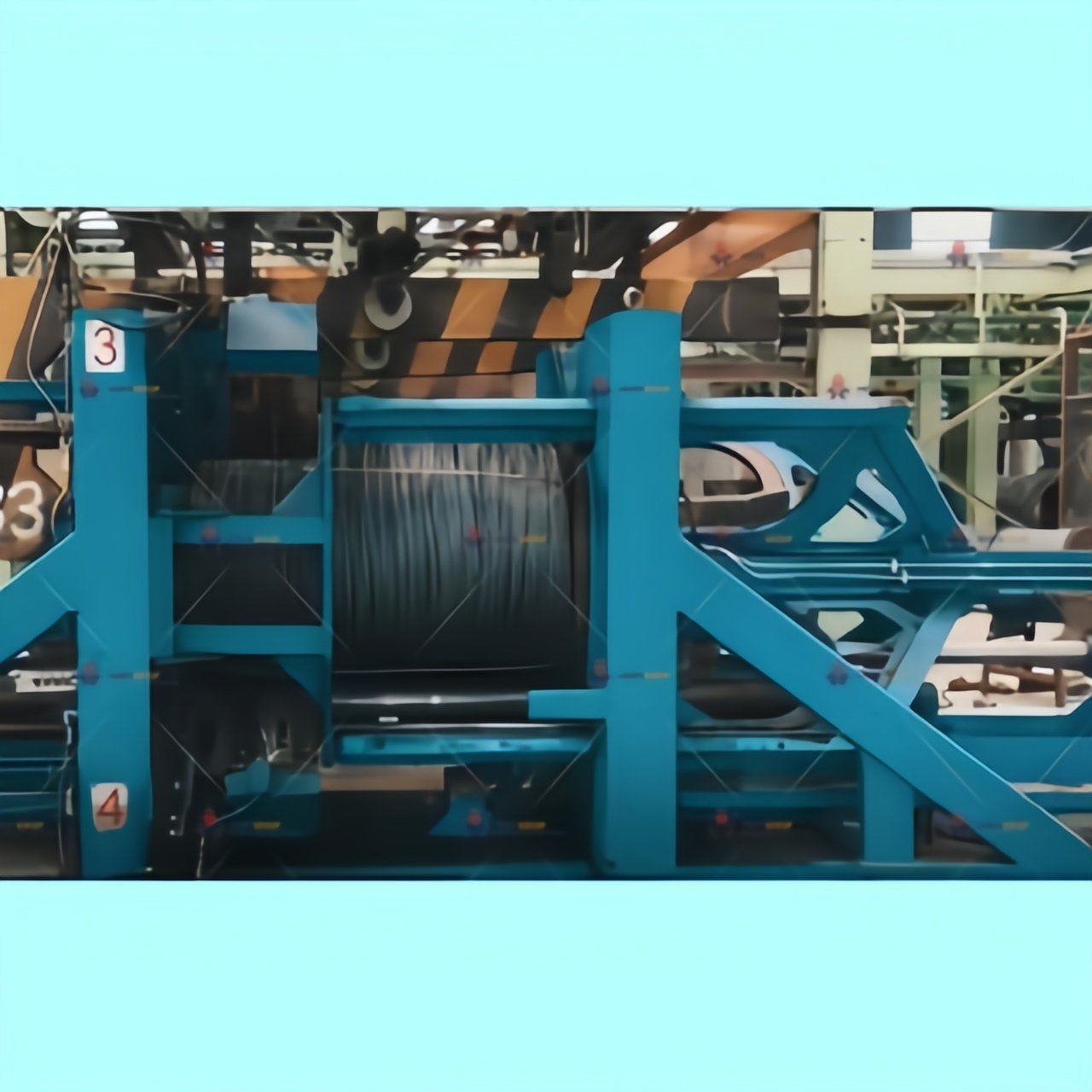

Wire compacting and strapping line

A Wire Compacting and Strapping Line is a specialized system designed to compact and securely strap wire coils or bundles. It ensures precise alignment, efficient compression, and durable strapping for easy handling and transport. This automated solution enhances productivity, reduces labor costs, and guarantees safe and reliable packaging for industrial wire products.

Wire Compacting and Strapping Line – Reliable Solutions for Wire Packaging

Fhope Packaging Machinery provides advanced wire compacting and strapping lines designed to streamline the packaging process for wire products. These systems ensure compact bundling and secure strapping, enhancing protection during transport and storage while reducing material waste. With customizable semi-automatic or fully automated options, Fhope’s solutions improve productivity and meet the demands of industries worldwide. Trusted for their durability and efficiency, these machines are ideal for modern wire manufacturing and packaging needs.

Ask For a Quick Quote

The first 3 people who consult today will receive a free consumable parts package.

Wire compacting and strapping line

Steel Wire Compression Bundling and Wrapping Packaging Line

The steel wire compression bundling and wrapping packaging line is a high-performance solution for securing and packaging steel wire products. It integrates compression, bundling, and wrapping functions to enhance stability and protection. Designed for efficiency, it ensures consistent results, making it ideal for industrial applications requiring robust packaging solutions.

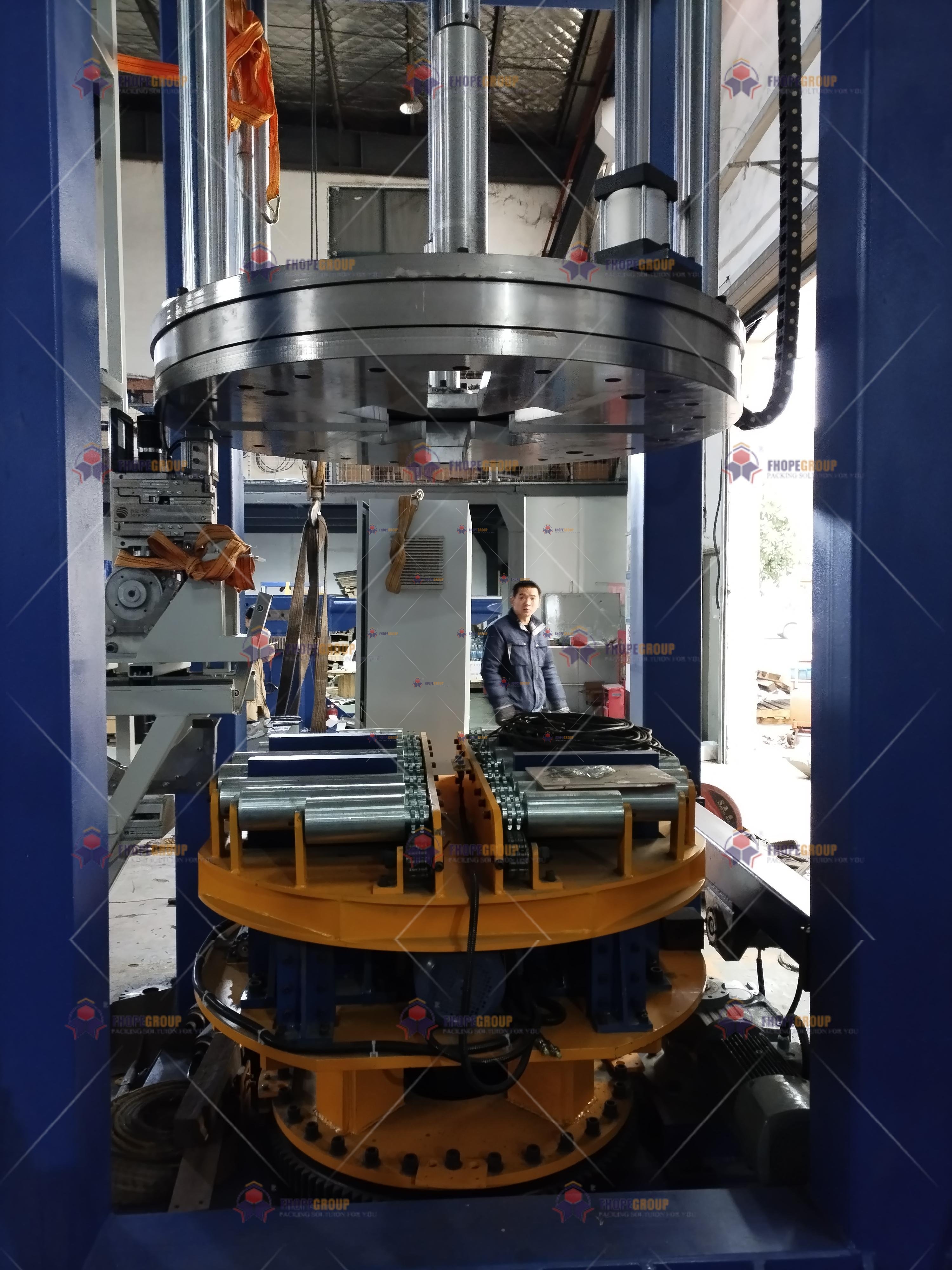

Automatic Steel Wire Compressor

An automatic steel wire compressor is a high-efficiency machine designed to compress and bundle steel wires for easier handling and transport. It automates the compression process, ensuring consistent pressure, precision, and time-saving benefits. Widely used in manufacturing and logistics, it enhances productivity and minimizes manual labor requirements.

Automatic Steel Wire Compression Strapping Machine

An automatic steel wire compression strapping machine is an advanced packaging solution designed for securing heavy loads with steel wires. It combines precision and efficiency, providing consistent compression and secure strapping. Ideal for industrial applications, it enhances safety, reduces labor costs, and ensures reliable bundling for transportation or storage.

Packaging Cases

We have exported to more than 50 countries. Powerful service internet and install team makes us build relationships with customers who come from European, Middle East, South America, South East Asia.

Get The Best Solutions for Your Building!

Why Choose Us

Superior design, uncompromising quality and a growing list of satisfied customers have made Fhope a pioneer in the industry. All main core parts with EN81-20 and 50 certificate

15+ years experience

With 15+ years experience in the packaging machinery industry, with deep understanding of the specific needs of various industries, including steel, automotive, and construction materials.

Professional Technical Team

10 mechanical engineer, 8 electrical engineer, 4 service engineer, with 15 high skill technician ensure the precise and innovative solutions.

OEM And ODM Design

With Excellent Technology and Advanced design, to make the machine in semiauto or automated matches to your packaging goal 100%

24/7 after services

We offer top-notch after-sales services including on-site installation, training, and maintenance support. Our dedicated team ensures minimal downtime and fast issue resolution to keep your production line efficient.

Top Cost performance

Engineered for Efficiency and Longevity. Benefit from our high cost performance machine with comprehensive support, including expert installation, thorough training, and responsive maintenance.

Global Standard

With installations in multiple countries, we have a global presence but also understand the specific requirements and regulations of regional markets. This allows us to offer localized support while maintaining high global standards.

Frequently Asked Questions

Here are the most common questions about packing machines. If you can’t find what you need, call us on +8613951501635 or get in touch at info@fhopepack.com.

How We Assist You in Selecting the Ideal Wire Compacting and Strapping Line?

Steel producers and industrial manufacturers often face challenges when selecting a reliable and efficient wire compacting and strapping line. Concerns about cost, reliability, and compatibility with existing workflows can hinder the decision-making process. At FHOPE, we aim to eliminate these barriers by offering tailored solutions that enhance efficiency and productivity.

Choosing the ideal wire compacting and strapping line involves analyzing production requirements, assessing ROI, and considering long-term benefits. With FHOPE's expertise, proven track record, and industry-leading equipment, we help you make informed decisions to streamline your operations and meet your goals.

Our goal is to guide you through every step, from understanding your needs to ensuring seamless integration and unparalleled support. Let’s explore how our approach guarantees satisfaction and operational excellence.

1. Which features of our Wire Compacting and Strapping Line align perfectly with your production requirements?

1.1 Customizable Solutions for Unique Production Needs

Wire compacting and strapping processes vary widely across industries. FHOPE’s solutions are built to adapt to specific production lines, addressing both current demands and future growth opportunities.

Our wire compacting and strapping line features modular designs, automated adjustments, and real-time monitoring systems that align with diverse production scales and complexities. This ensures compatibility, improved throughput, and reduced downtime.

1.2 Advanced Features to Optimize Productivity and Quality

FHOPE's wire compacting and strapping lines are equipped with state-of-the-art technology that enhances operational efficiency while maintaining product quality. These features include:

Automated Tension Control: Maintains consistent strapping tension for secure wire bundles.

Real-Time Diagnostics: Identifies operational inefficiencies, minimizing unplanned downtime.

Energy-Efficient Motors: Reduces power consumption without compromising performance.

Integrated Data Analytics: Tracks production metrics for continuous improvement.

| Feature | Benefit |

|---|---|

| Automated Tension Control | Prevents loose or overly tight straps |

| Real-Time Diagnostics | Minimizes downtime through quick fixes |

| Energy-Efficient Motors | Lowers operational costs |

| Integrated Data Analytics | Enhances decision-making processes |

1.3 How Modular Designs Enable Scalability

Our modular designs offer unmatched flexibility, ensuring seamless integration with your existing production systems. Whether scaling up or diversifying product offerings, these systems evolve with your business.

Modular systems allow manufacturers to add or replace components without overhauling the entire line. This flexibility saves costs and time, keeping production running smoothly even during upgrades. For example, FHOPE offers interchangeable tooling that simplifies the transition between different wire bundle sizes.

Interchangeable Tooling: Quickly adapts to different wire diameters and configurations.

Expandable Modules: Add automation features as production demands increase.

1.4 The Role of Coil Upenders in Improving Efficiency

Coil upenders are essential for rotating heavy wire spools safely and efficiently during compacting and strapping. Our coil upenders are engineered to handle loads ranging from 500 kg to 20 tons, reducing manual handling and ensuring precision.

Key Benefits of Coil Upenders

| Attribute | Explanation |

|---|---|

| Load Versatility | Accommodates various coil sizes |

| Safety Features | Prevents accidents during rotation |

| Integration Compatibility | Works seamlessly with strapping lines |

Using a coil upender eliminates risks associated with manual lifting and enhances operator safety. Its precise controls allow operators to position coils effortlessly, streamlining the workflow and minimizing downtime.

1.5 Two Fact Statements with Explanation

True: FHOPE's wire compacting lines include automated tension control, which improves strapping consistency and prevents bundle deformation. This feature directly reduces the need for rework.

False: Manual intervention is required at every stage of FHOPE's compacting lines. Our systems are fully automated, minimizing the need for hands-on adjustments.

2. How do our expertise and established industry reputation guarantee a dependable partnership?

2.1 Proven Track Record with Leading Manufacturers

With over a decade of experience in designing and manufacturing wire compacting and strapping solutions, FHOPE has built a strong reputation as a trusted partner for leading manufacturers across various industries. Our expertise lies in understanding the unique challenges of wire handling and packaging, ensuring our solutions are always tailored to optimize both quality and productivity.

FHOPE’s long-standing relationships with top-tier manufacturers are a testament to our commitment to excellence. Our customers repeatedly choose us due to our ability to consistently meet their evolving needs with innovative, reliable equipment.

2.2 Our Team’s Industry Expertise and Knowledge

At FHOPE, our team comprises highly skilled engineers, technicians, and customer support experts who possess in-depth knowledge of wire compacting and strapping technologies. From the initial consultation to after-sales service, our team works closely with you to ensure that the solution fits seamlessly into your production line.

Our engineers are continually trained on the latest technologies and industry trends, allowing them to offer cutting-edge solutions to meet the most challenging production demands.

2.3 Leveraging Industry Certifications for Guaranteed Quality

FHOPE’s solutions are built to meet international industry standards, such as ISO 9001:2015 and CE certifications. These certifications verify that our manufacturing processes, product quality, and customer service adhere to global best practices. This assurance translates into dependable equipment that can withstand the rigors of industrial use.

Additionally, we conduct extensive quality checks on every unit produced, ensuring that each piece of equipment is fully functional and meets the highest standards before it leaves our factory.

ISO 9001:2015 Certification: Ensures systematic quality management practices across the entire production process.

CE Certification: Guarantees compliance with European safety and environmental standards.

2.4 FHOPE’s Reputation in the Global Market

Over the years, FHOPE has built a global presence, with customers spanning Europe, North America, and Asia. We take pride in our ability to deliver highly efficient wire compacting and strapping solutions that meet the diverse needs of our international clientele.

We understand that a dependable partner is key to ensuring consistent quality and meeting tight production deadlines. Our established reputation ensures that we are a partner you can rely on for the long term.

2.5 Two Fact Statements with Explanation

True: FHOPE’s established reputation has earned us long-term partnerships with major manufacturers in various industries, including automotive, construction, and wire processing.

False: FHOPE’s wire compacting lines have never been tested under real-world production conditions. In fact, we rigorously test all our systems in actual production environments before they are delivered.

3. How do we ensure cost transparency to help you assess ROI with confidence?

3.1 Clear Pricing Structure for Informed Decision Making

When purchasing a wire compacting and strapping line, understanding the total cost of ownership is critical to making an informed decision. FHOPE offers a transparent pricing model that provides a complete breakdown of costs, including equipment, installation, training, and ongoing maintenance.

Our transparent cost breakdowns empower customers to make cost-effective decisions by providing a clear understanding of initial investment, operational expenses, and long-term savings.

3.2 Factors Contributing to ROI Assessment

Investing in wire compacting and strapping lines is not just about the upfront cost but also about the return on investment (ROI) over time. FHOPE ensures that our solutions deliver high ROI by focusing on several key areas:

Energy Efficiency: Our equipment reduces power consumption, leading to lower operational costs over time.

Increased Throughput: Our systems’ automation features allow for faster, more efficient production, reducing labor costs and improving overall productivity.

Reduced Maintenance Costs: FHOPE’s durable design and advanced diagnostic features result in fewer breakdowns and lower maintenance expenses.

| Factor | Impact on ROI |

|---|---|

| Energy Efficiency | Reduces utility costs by 20-30% |

| Increased Throughput | Boosts production speed by 15-20% |

| Reduced Maintenance Costs | Lowers maintenance costs by 10-15% |

3.3 Financial Flexibility and Support

We also understand that large capital expenditures can be a significant consideration for many companies. That’s why FHOPE offers flexible financing options, including leasing and installment plans, to help you manage your investment without compromising cash flow.

Moreover, our dedicated finance team is available to provide guidance on financing options and ROI analysis, ensuring that you can make the best decision for your business.

3.4 Detailed Cost Breakdown and Long-Term Value

We believe in providing complete cost transparency, which is why we offer a detailed breakdown of the cost involved in procuring, installing, and maintaining our wire compacting and strapping line. Our customers can compare this information against expected operational savings and increased productivity to assess the overall value.

This approach helps you understand the true cost-to-benefit ratio and ensures that your investment is optimized for long-term gains.

3.5 Two Fact Statements with Explanation

True: FHOPE provides detailed cost breakdowns for all wire compacting and strapping lines, helping you make a well-informed investment decision.

False: FHOPE charges hidden fees for maintenance and service contracts. In reality, all our service agreements are clearly outlined in the contract.

4. How do our extensive after-sales services ensure uninterrupted operations for your business?

4.1 Comprehensive After-Sales Support for Seamless Operations

At FHOPE, we understand that ongoing support after installation is crucial for maintaining smooth operations. Our after-sales services are designed to ensure that your wire compacting and strapping systems remain fully operational throughout their lifecycle. From troubleshooting to routine maintenance, we are committed to providing timely and effective support.

Our after-sales services are a key component of our commitment to customer satisfaction. By offering 24/7 technical support, spare parts availability, and preventive maintenance, we minimize downtime and ensure your business operates efficiently.

4.2 Continuous Monitoring and Proactive Maintenance

To reduce the risk of unexpected breakdowns, FHOPE offers a range of proactive maintenance programs. Our technical support team works closely with you to monitor the health of your wire compacting and strapping system and schedule maintenance activities at convenient times.

We also use advanced monitoring tools that allow us to remotely diagnose and troubleshoot issues, ensuring that we can address potential problems before they escalate. This proactive approach extends the lifespan of your equipment and ensures consistent performance.

Remote Monitoring: Continuous remote diagnostics allow us to detect early warning signs of potential issues.

Preventive Maintenance: Scheduled service visits to inspect and maintain equipment, ensuring that it remains in top condition

4.3 Rapid Response and Spare Parts Availability

In the event of a breakdown or malfunction, FHOPE guarantees rapid response times to minimize downtime. We maintain an extensive inventory of spare parts at strategic locations, ensuring that the necessary components are readily available when needed.

Our service team is available 24/7 to resolve any issues, and we are committed to dispatching technicians promptly to address on-site needs. This rapid response ensures that your production line can resume operations with minimal delay.

4.4 Ongoing Training and Technical Support

FHOPE also offers ongoing training programs for your operators and maintenance staff. Our team provides on-site and remote training sessions to ensure that your team is fully equipped to operate and maintain the wire compacting and strapping systems effectively.

Through regular training updates, we ensure that your staff stays informed about the latest features, safety practices, and troubleshooting techniques, ultimately improving productivity and reducing errors.

4.5 Two Fact Statements with Explanation

True: FHOPE offers 24/7 technical support and proactive maintenance programs, ensuring continuous operations and reducing downtime.

False: FHOPE’s after-sales support is limited to installation only. In fact, we offer comprehensive ongoing support, including remote monitoring, training, and spare parts availability.

5. What makes our Wire compacting and strapping line capable of surpassing safety and compliance standards?

5.1 Meeting Industry Safety Standards

Safety is a priority at FHOPE, and our wire compacting and strapping lines are designed with the highest safety standards in mind. Our equipment is built to comply with various international safety regulations, including OSHA (Occupational Safety and Health Administration) guidelines and CE certifications.

We focus on ensuring that all systems are equipped with safety features such as emergency stop buttons, safety interlocks, and automatic shutdown systems. These features protect your workers and reduce the risk of accidents during operation.

FHOPE's commitment to safety ensures that our equipment meets or exceeds regulatory requirements, keeping your team safe and your operations compliant.

5.2 Compliance with Environmental Standards

In addition to safety, FHOPE ensures that our wire compacting and strapping lines are compliant with global environmental standards. Our systems are designed to minimize waste, reduce energy consumption, and use sustainable materials in manufacturing.

We also make it a point to continuously review and update our designs to meet evolving environmental standards. This forward-thinking approach helps you maintain compliance with regulatory bodies and reduces your environmental footprint.

Energy-Efficient Motors: Our compacting systems use energy-efficient motors to lower power consumption.

Sustainable Materials: We prioritize environmentally friendly materials in the production of our wire strapping systems.

5.3 Enhancing Worker Safety with Ergonomic Design

FHOPE designs our wire compacting and strapping lines with ergonomics in mind to ensure that workers can operate and maintain the systems safely and comfortably. Our machines are equipped with adjustable controls, easy-to-reach panels, and clear instructions, making it easier for operators to work without strain or risk.

Additionally, our machines are designed with safety enclosures, guarding, and emergency stop features to protect workers from moving parts and hazardous situations.

5.4 Continuous Monitoring for Compliance

FHOPE integrates continuous monitoring capabilities into our wire compacting and strapping lines to ensure ongoing compliance with safety and environmental regulations. Our systems are equipped with sensors that track key parameters such as temperature, pressure, and vibration, providing real-time data to ensure that all operations are within safe limits.

These sensors also alert operators if any safety thresholds are breached, enabling immediate corrective action to be taken.

5.5 Two Fact Statements with Explanation

True: FHOPE’s wire compacting and strapping lines are designed with multiple safety features, including emergency stops and safety interlocks, to ensure worker protection.

False: FHOPE’s equipment does not meet environmental compliance standards. In fact, all our systems adhere to the latest environmental regulations, reducing waste and energy consumption.

6. How do our training programs and technical support guarantee seamless integration?

6.1 Comprehensive Training Programs for Seamless Integration

At FHOPE, we believe that the key to successfully integrating new equipment into your production line is proper training. Our training programs are designed to ensure that your team is fully prepared to operate the wire compacting and strapping systems with confidence and efficiency. Whether you are implementing the system for the first time or upgrading an existing setup, we provide personalized training sessions that cater to the specific needs of your workforce.

Our training covers everything from basic operation and setup to advanced troubleshooting and maintenance, ensuring that your team can keep the system running smoothly without needing constant external support.

6.2 On-Site and Remote Training Options

We understand that every company is different, and flexibility is essential when it comes to training. FHOPE offers both on-site and remote training options to ensure that your team receives the support they need regardless of location.

On-Site Training: Our experts will visit your facility to provide hands-on training to your operators and maintenance teams. This personalized approach ensures that your team is familiar with your specific setup and production needs.

Remote Training: For companies with multiple locations or remote facilities, we offer online training modules and virtual consultations. These sessions allow your team to learn at their own pace while still receiving guidance from FHOPE experts.

6.3 Continuous Technical Support After Training

Even after your team completes the training, FHOPE’s technical support team remains available to provide ongoing assistance. Whether it’s a quick question about system settings or in-depth troubleshooting, we are here to help.

We also offer access to our knowledge base, which includes FAQs, troubleshooting guides, and video tutorials. This ensures that your team always has the resources they need, even when we are not physically on-site.

Video Tutorials: Step-by-step guides and troubleshooting videos to help your team resolve issues efficiently.

24/7 Support: Our technical support team is available around the clock to provide immediate assistance when needed.

6.4 Real-Time Support for Quick Issue Resolution

In addition to training, FHOPE offers real-time support through our advanced monitoring systems. If your equipment encounters an issue, our team can remotely access the system to provide troubleshooting assistance, reducing downtime and speeding up resolution.

Our goal is to empower your team with the knowledge and tools they need to operate the wire compacting and strapping systems independently, while also ensuring that expert support is just a call or click away.

6.5 Two Fact Statements with Explanation

True: FHOPE provides both on-site and remote training, ensuring that all operators are well-equipped to use the equipment effectively.

False: FHOPE’s training is one-time only and does not provide ongoing support. In fact, we offer continuous technical support and resources even after the training is complete.

7. How do we tailor and future-proof our Wire compacting and strapping line to align with your long-term growth plans?

7.1 Tailored Solutions for Your Unique Needs

At FHOPE, we know that no two businesses are alike. That’s why we offer customized solutions designed to fit the unique needs of your production process. Whether you need a specialized setup for wire compacting or additional features for greater flexibility, our team works closely with you to design a system that meets your specifications.

By thoroughly understanding your production requirements and goals, we ensure that the equipment we provide integrates seamlessly into your existing processes and supports your long-term objectives.

7.2 Scalable Systems for Growing Production

As your business grows, so too should your wire compacting and strapping systems. FHOPE designs our systems with scalability in mind, allowing for easy upgrades as your production demands increase. Whether it's increasing capacity, adding automation features, or integrating with other equipment, our systems can be expanded to accommodate your future needs.

We also offer modular components that can be added over time, giving you the flexibility to upgrade your systems without having to completely replace them.

Modular Components: Easily add new features and components as your business grows.

Flexible Design: Systems designed for easy scalability, ensuring they can adapt to future production needs

7.3 Ongoing R&D for Future-Ready Solutions

FHOPE is committed to continuous research and development to ensure that our systems remain at the forefront of technology. Our R&D team constantly explores new materials, automation technologies, and design innovations that can be incorporated into our wire compacting and strapping lines. This ensures that you are always using cutting-edge equipment that can support the evolving demands of your business.

7.4 Future-Proofing Your Investment

Investing in new equipment is a big decision, and you want to be sure that your investment will provide value for years to come. FHOPE’s wire compacting and strapping lines are designed with future-proofing in mind. We use durable materials, cutting-edge technologies, and scalable designs that ensure your system remains relevant and efficient as your business grows.

By investing in FHOPE’s equipment, you’re ensuring that your production line is prepared to handle future challenges and opportunities.

7.5 Two Fact Statements with Explanation

True: FHOPE designs its wire compacting and strapping lines to be scalable, ensuring they can grow with your business.

False: FHOPE equipment is fixed and cannot be upgraded. In fact, our systems are modular and can be easily expanded or upgraded as needed.

8. How do we ensure our delivery timelines and installation process are smooth and hassle-free?

8.1 Streamlined Delivery Process for Timely Installation

At FHOPE, we understand that timely delivery and smooth installation are crucial to keeping your production line on schedule. Our dedicated logistics team works closely with your company to ensure that all equipment is delivered within the agreed timelines. We also offer multiple shipping options, including air, sea, and land freight, to ensure that your equipment reaches your facility safely and on time, no matter where you are located.

We know that any delays in equipment arrival can result in downtime, which is why we track each delivery closely and keep you informed of its status every step of the way. This proactive communication allows you to plan and prepare for the installation process, minimizing any disruptions to your operations.

8.2 Efficient Installation Process with Minimal Downtime

Once the equipment arrives at your facility, FHOPE’s installation team is ready to get it up and running as quickly as possible. Our experts are trained to handle all aspects of the installation process, including site preparation, equipment setup, and system integration. We also ensure that all safety standards are met during the installation to guarantee the security of your operators and equipment.

We know that every minute of downtime affects your bottom line, so we aim to complete the installation and testing phases as quickly and efficiently as possible. Our goal is to have your wire compacting and strapping line fully operational in the shortest time frame, minimizing any impact on your production schedule.

Quick Setup: Our installation teams are trained to set up systems quickly, reducing downtime.

Safety Compliance: We adhere to all safety standards during installation to protect your team and equipment.

8.3 Post-Installation Support and Training

Once the system is installed, FHOPE provides comprehensive post-installation support to ensure that your team is confident in operating the equipment. This includes additional training sessions, system checks, and troubleshooting if necessary. We work closely with you during the initial phase of operation to address any questions or concerns.

Our goal is not just to install equipment but to ensure that your team can operate it independently and efficiently as soon as possible. With our ongoing support and training, you can feel confident that your production line will continue to run smoothly.

8.4 Two Fact Statements with Explanation

True: FHOPE guarantees timely delivery and efficient installation to minimize downtime.

False: FHOPE’s installation process is slow and may cause significant downtime. In fact, our team works quickly to complete installations with minimal disruption to your operations.

9. How do our success stories and case studies demonstrate the reliability of our solutions?

9.1 Proven Success Across Multiple Industries

FHOPE has a long history of providing reliable wire compacting and strapping lines to businesses across various industries, including automotive, construction, and manufacturing. Our success stories and case studies showcase the effectiveness of our solutions and demonstrate the impact they’ve had on our clients’ operations. We believe that our track record speaks for itself and that our clients’ success is a testament to the quality and reliability of our products.

We have worked with numerous companies to improve their packaging processes, reduce downtime, and enhance overall efficiency. Each success story highlights how FHOPE’s solutions have addressed specific challenges and provided lasting value.

9.2 Detailed Case Studies for In-Depth Insights

Our case studies provide a detailed look at the challenges faced by our clients, the solutions we implemented, and the results achieved. These case studies allow potential customers to see how FHOPE’s equipment can be used in real-world applications to achieve measurable improvements in efficiency and productivity.

From reduced manual labor costs to improved packaging consistency, our case studies demonstrate the tangible benefits of our wire compacting and strapping lines. We invite you to explore our success stories to see how we’ve helped other businesses achieve their goals.

Client A Case Study: Reduced downtime by 30% and improved packaging speed by 25%.

Client B Case Study: Cut labor costs by 40% through the implementation of automation solutions.

9.3 Client Testimonials and Feedback

In addition to case studies, we also collect and share feedback from our clients to give you a firsthand look at their experience working with FHOPE. Client testimonials often highlight our commitment to customer service, the reliability of our products, and the impact our systems have had on their production processes. We take great pride in the long-term relationships we build with our clients, and their feedback reflects our dedication to providing excellent service and high-quality solutions.

9.4 Two Fact Statements with Explanation

True: FHOPE has a proven track record of successful case studies and client testimonials that highlight the reliability of our solutions.

False: FHOPE’s solutions have not been proven effective in real-world applications. In fact, our extensive case studies demonstrate the positive impact our systems have had on a variety of industries.

10. How do our transparent and flexible contract terms safeguard your investment?

10.1 Clear and Transparent Contractual Terms

When it comes to investing in a new wire compacting and strapping line, we believe that transparency is key. At FHOPE, we ensure that all contract terms are clear, straightforward, and easy to understand. From pricing to delivery timelines and installation, we outline every detail in the agreement, so there are no surprises along the way. This transparency helps foster trust between us and our clients, as it allows them to fully understand the scope of their investment and what to expect throughout the process.

We believe in full disclosure of all costs, including any potential additional charges, so you can make an informed decision. Our goal is to eliminate any ambiguity and ensure that you feel confident in your investment from the outset.

10.2 Flexible Payment Terms to Suit Your Needs

We understand that every business has unique financial needs. That’s why we offer flexible payment terms tailored to your specific situation. Whether you prefer to pay in installments or opt for an upfront payment, we are open to negotiating the payment structure that best suits your cash flow. By offering these flexible options, we aim to reduce the financial burden on our clients while still delivering the best possible value.

We also provide financing options through trusted third-party partners for companies that may require additional support. Our flexible terms help ensure that financial constraints do not stand in the way of acquiring the equipment your business needs.

Custom Payment Plans: Flexible terms that align with your business’s financial situation.

Full Cost Disclosure: Transparent pricing to ensure you know exactly what to expect.

10.3 Protection for Your Investment

We also believe that a strong contract should offer protection for your investment. In the event of any unforeseen circumstances or delays, our contracts include clauses that protect you from additional costs and extend our responsibility for the timely delivery and installation of your equipment. We stand by our products and services, and our contracts reflect this commitment to your business’s success.

Additionally, we offer warranty terms that guarantee the quality and durability of our wire compacting and strapping lines. Should any issues arise during the warranty period, our team will address them promptly, ensuring that your operations are not disrupted.

10.4 Two Fact Statements with Explanation

True: FHOPE’s contracts offer clear, transparent terms, flexible payment options, and protection for your investment.

False: FHOPE’s contracts are complicated and filled with hidden costs. In reality, our agreements are straightforward, with all costs clearly outlined.

Conclusion

Choosing the right wire compacting and strapping line is a significant investment for your business, and at FHOPE, we strive to make the decision-making process as smooth and informed as possible. From understanding the features that align with your production needs to the assurance that our expertise and transparent contracts safeguard your investment, we are here to provide not just a product, but a reliable, long-term partnership. With our after-sales services, flexible payment terms, and proven success in the industry, we aim to ensure that your investment in automation brings measurable value, efficiency, and growth.

We are committed to delivering excellence at every step, from pre-purchase consultations to post-installation support. Let FHOPE be your trusted partner in achieving a streamlined, future-proof wire compacting and strapping solution that supports your business goals for years to come.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635