Automatic Steel Wire Compression Strapping Machine

The machine is designed for fully automatic compression and strapping of wire materials like aluminum wire, galvanized steel wire, steel rope, and wire coils. It integrates compression, positioning, and strapping, ensuring efficiency and reliability for industrial applications.

Key Features:

Suitable for PET/steel belt strapping with 2/4 straps per coil.

Simple structure, easy operation, and low noise.

Integrated manual and automatic control options.

High-power cooler for extended operation.

Stable pressure regulation with overload protection.

Special Features

Related video

An automatic steel wire compression strapping machine is an advanced packaging solution designed for securing heavy loads with steel wires. It combines precision and efficiency, providing consistent compression and secure strapping. Ideal for industrial applications, it enhances safety, reduces labor costs, and ensures reliable bundling for transportation or storage.

Automatic Steel Wire Compression Strapping Machine

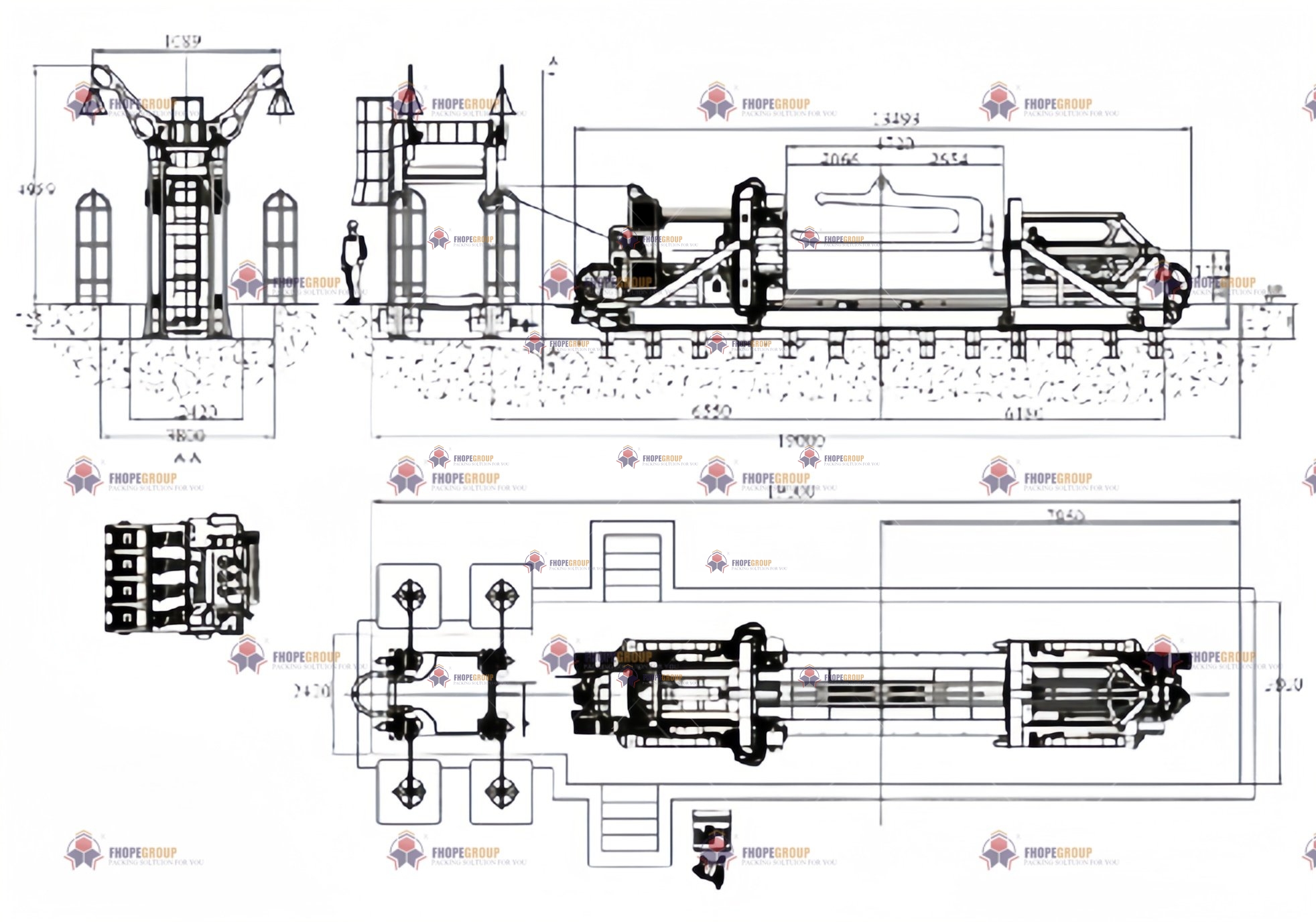

The wire compression strapping machine consists of a compactor, lifting rollers, strapping heads, electrical cabinet, pneumatic and hydraulic devices. It can be integrated with a preceding C-hook handling line for automatic wire compression and strapping.

The automatic steel wire compression strapping machine is suitable for fully automatic compression and strapping of various wire materials, including aluminum wire, galvanized steel wire, steel rope, wire coils, stranded wire, and rebar coils.

Operation Process:

Use C-hooks or similar lifting tools to transfer wire coils to the compression and strapping station.

Automatically check the position and place the material on the rollers.

Automatic compression.

After compression, the PET/steel belt strapping head performs strapping, with 2 or 4 straps per coil.

The strapped material is transported out of the compression and strapping station.

One cycle is completed, and the process repeats.

Basic Features of the Hydraulic Pump Station:

A workbench with gaps for manual strapping convenience.

Simple structure, easy operation, safe and reliable, low noise, and stable performance.

Integrated manual and automatic switches.

External motor switch for remote operation.

Special integrated circuit board: stops the unloading pump after 1 minute, automatically releases pressure, and provides overload protection.

External high-power cooler for extended operation.

Special pressure regulating valve for stable pressure control.

Allows operation under pressure at any time.

Lighter, faster, with higher flow and greater efficiency.

| Item | Specification |

|---|---|

| Material | Steel Wire Coils/Steel Ropes/Strands/Wire Rods, etc. |

| Number of Binding Heads | 4 |

| Binding Time | Approx. 60 seconds |

| Coil Inner Diameter | 700 - 1200 mm |

| Coil Outer Diameter | 1000 - 1600 mm |

| Coil Width | 1000 - 3000 mm |

| Coil Weight | ≤10T |

| Binding Material | Steel Straps |

| Operation | Automatic/Manual |

| Power Supply | 380 V, Three-Phase, Five-Wire |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635