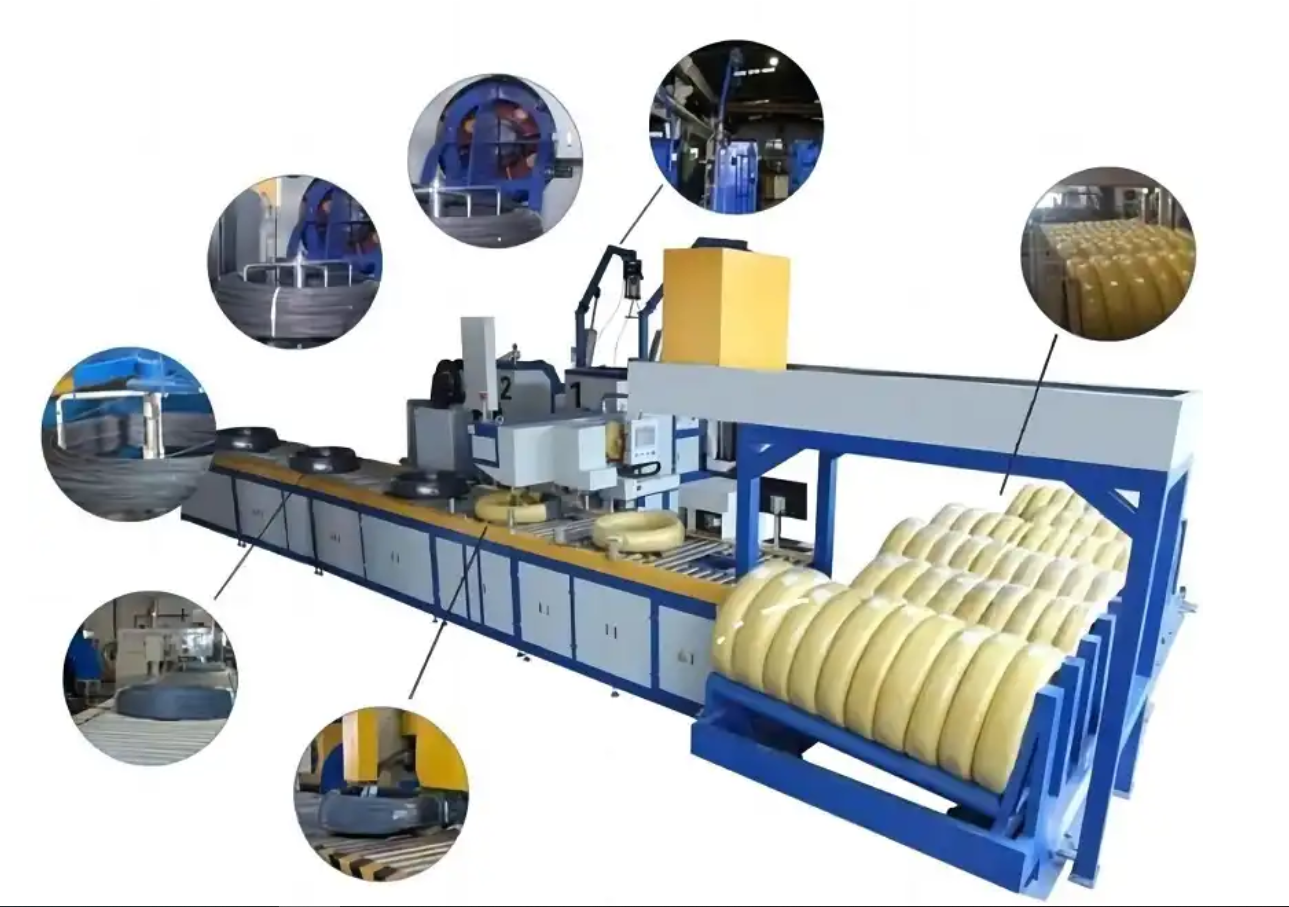

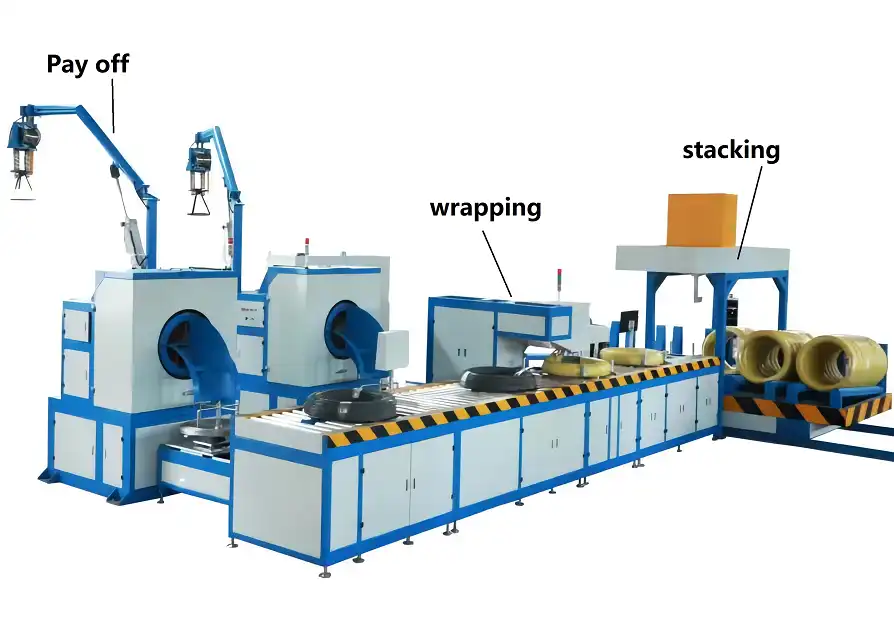

Automatic steel wire winder and packing line

The Automatic Steel Wire Packing Line is a highly advanced and efficient solution designed to streamline the packaging process for wire and cable products. With its programmable control system, flexible functionality, and user-friendly interface, this machine is engineered to enhance productivity, safety, and adaptability while maintaining low maintenance costs.

Benefits

Operational Efficiency: High packaging speed and multi-functional capabilities enhance productivity.

Cost Savings: Low maintenance and labor costs, reduced downtime, and optimized resource use.

Enhanced Safety: Automated features and safe placement of controls improve workplace safety.

Reliability: Use of well-known brand components ensures consistent performance and longevity.

Special Features

Related video

An automatic steel wire winder and packing line is an advanced system designed to streamline the coiling and packaging of steel wires. It automates winding, securing, and packing, ensuring efficiency and consistent quality. Ideal for industrial use, it reduces manual labor, boosts productivity, and enhances packaging reliability for safe transportation and storage.

Automatic Steel Wire Packing Line: Advanced, Efficient, and Reliable

The Automatic Steel Wire Packing Line is a highly automated solution designed to meet the evolving needs of the steel wire and cable industries. With features such as manual or automatic operation modes, programmable control systems, and customizable packaging settings, this machine is a cutting-edge tool for improving operational efficiency, safety, and flexibility.

Core Features and Capabilities

1. Flexible Operational Modes

Operates in manual or automatic mode, allowing users to switch based on production needs.

Equipped with a programmable control system and human-machine interface (HMI) for seamless operation.

2. Customizable Packaging Options

Automatically adjusts packaging details based on input product size parameters.

Offers multiple packaging methods with the ability to select and adjust materials, such as plastic or paper, to suit specific customer needs.

3. High Automation and Efficiency

Features automatic function settings through data input, minimizing manual intervention.

Includes a trolley system for efficient transportation of packaged coils.

Low maintenance costs and durable design ensure long-term reliability and reduced downtime.

4. Enhanced Safety and Usability

The control cabinet is strategically placed at a safe distance, prioritizing operator safety.

High packaging speed improves productivity while maintaining safe operations.

Automatic alarm system detects and reports errors, allowing quick identification and resolution of issues.

5. Quality Components and Robust Build

Constructed with a steel external frame for strength and stability.

Designed with aesthetic color options for a visually appealing appearance.

Incorporates high-quality components from Siemens, Mitsubishi, and AirTAC, ensuring exceptional reliability and performance.

Key Advantages

1. Operational Efficiency

Multi-Functional Packaging:

Meets diverse packaging requirements, including protective wrapping for storage and transportation.

Ensures flexibility in manufacturing wire coils of various specifications to meet customer demands.

Automated Reporting:

Generates statistics and reports automatically, reducing administrative workload and packaging costs.

2. Enhanced User Experience

Convenient Adjustments:

Easy-to-use controls make the machine user-friendly, even for operators with minimal experience.

Safety-First Design:

Ensures operator safety with strategically placed components, emergency stop mechanisms, and robust alarms.

3. Cost and Time Savings

Reduced Maintenance Costs:

Durable components minimize wear and tear, ensuring longer intervals between servicing.

Lower Labor Costs:

Automation reduces the need for manual labor, boosting productivity and efficiency.

4. Aesthetic and Functional Design

The steel frame and attractive color options enhance the machine's visual appeal while maintaining durability.

Applications in Industry

The Automatic Steel Wire Packing Line is ideal for:

Steel Wire and Cable Manufacturing

Industrial Packaging Operations

Warehousing and Distribution Centers

Technical Features

Packaging Materials:

Supports various materials like plastic and paper for tailored product protection.

Automation System:

Uses PLCs from Siemens and Mitsubishi for reliable control.

Pneumatic components from AirTAC enhance functionality and durability.

Error Detection and Reporting:

Automatic alarm system identifies and resolves failures, reducing downtime.

Statistics and Reporting:

Automatically generates operational statistics, providing insights into efficiency and cost-saving opportunities.

Why Choose the Automatic Steel Wire Packing Line?

Efficiency and Productivity:

High-speed packaging and multi-functional capabilities reduce production time and costs.

Reliability and Durability:

Incorporates premium components and robust construction for long-lasting performance.

Flexibility and Customization:

Adapts to various wire coil sizes, packaging materials, and customer-specific requirements.

Safety and Ease of Use:

Prioritizes user safety with thoughtful design and automated error reporting.

Cost Savings:

Reduces labor and packaging costs through automation and operational efficiency.

Conclusion

The Automatic Steel Wire Packing Line is an indispensable tool for businesses seeking to enhance their packaging processes. By combining advanced automation, superior build quality, and user-friendly features, this machine delivers exceptional performance, safety, and efficiency. Its ability to adapt to diverse needs while reducing operational costs makes it an ideal choice for modern industrial packaging operations.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635