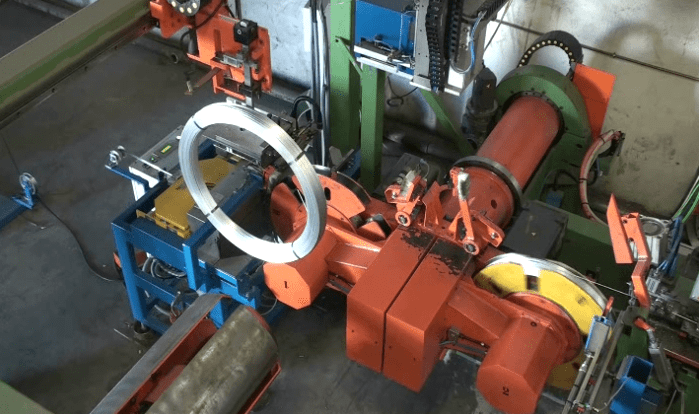

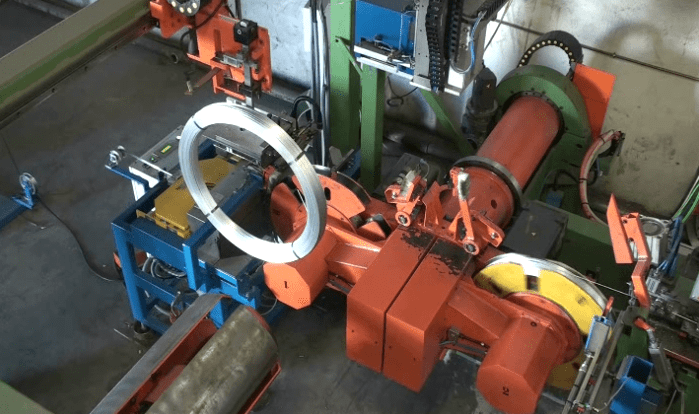

Automatic wire coiler

The Automatic Wire Coiler is an advanced machine designed to meet the demanding needs of the steel wire industry. Fully automated and equipped with the latest technology, it streamlines wire coiling and strapping processes, reducing labor costs, minimizing waste, and ensuring precise, high-quality results. Its customizable and efficient design makes it ideal for industries requiring reliable and consistent wire handling solutions.

Key Features:

High Efficiency: Handles up to 40 coils per hour (double head) with precise coiling and strapping.

Customizable: Supports various wire diameters and coil sizes with adjustable tension control.

Automation: Features PLC control, dual coiling heads, and automated feeding, winding, and cutting.

Safety and Reliability: Includes emergency stop buttons, anti-collision systems, and limit switches.

Special Features

Related video

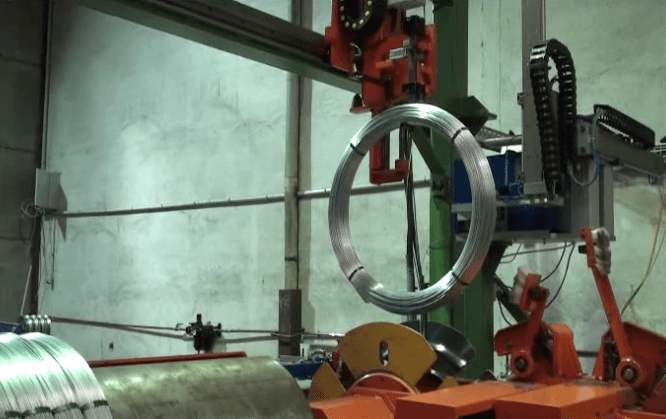

An automatic wire coiler is a specialized machine that automates the coiling, cutting, and packaging of wires. It enhances efficiency in production lines, offering precise and consistent results. Widely used in industries like cable manufacturing, it reduces manual labor, improves productivity, and ensures high-quality wire handling.

Automatic Wire Coiler: Advanced Solution for the Steel Wire Industry

The Automatic Wire Coiler is a state-of-the-art machine tailored to address the critical needs of the steel wire industry. Designed according to CE guidelines and powered by the latest technology, it offers a fully automated solution for wire coiling and strapping. This system effectively addresses challenges like manpower shortages and irregular winding coils, ensuring enhanced productivity, reduced waste, and consistent results.

Applications and Benefits

Comprehensive Solution for Wire Coiling and Strapping

Ideal for steel wires across various specifications and sizes.

Ensures secure coiling and strapping, reducing product damage during storage and transit.

Productivity Boost

Automates the entire wire coiling process, handling large volumes efficiently.

Reduces manual labor, cutting costs while increasing output.

Enhanced Product Quality

Eliminates irregular winding, ensuring neat and tidy coils.

Advanced tension control prevents overstretching or breaking wires.

Turnkey Support

FHOPE provides end-to-end solutions, including sales, service, and engineering support, to design optimized packaging systems tailored to specific customer requirements.

Core Components and Functions

A. Vertical Tension Wire Accumulator

Assembled with steel plates and powered by a reducing-speed motor.

Wire-accumulating length: 5m–20m.

Adjustable Tension: Controlled via a tension cabinet with DC-24V power.

Includes safety features like limit switches at the front and back to prevent overstretching or wire breaks.

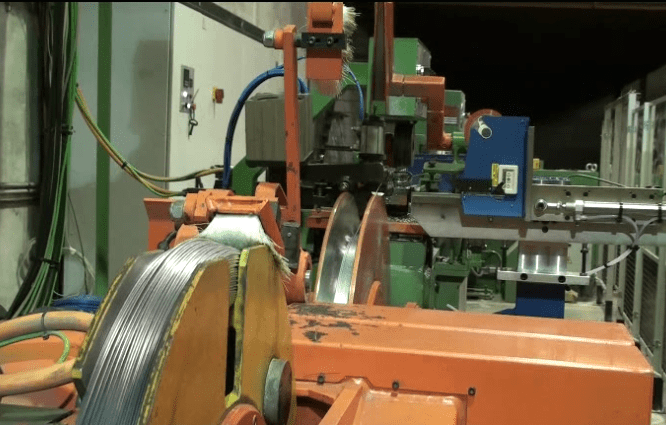

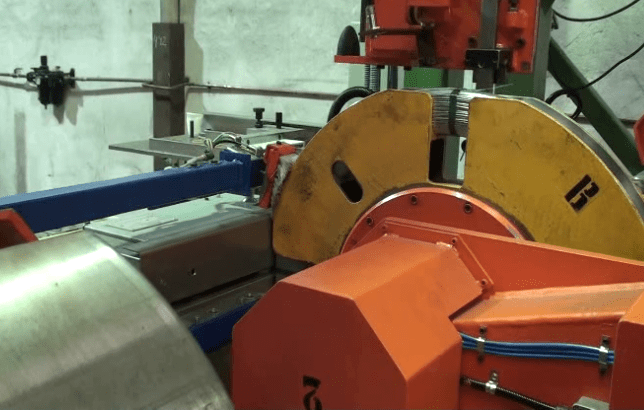

B. Automatic Coiling Machine

Dual Coiling Heads: Enable continuous wire winding for uninterrupted operations.

Automated processes: Wire feeding, winding, and cutting are fully automated, improving efficiency.

PLC Control: Stores wire reel specifications for quick changes and consistency.

Features an alarm system for detecting and signaling issues.

Equipped with an overlength forecast system to automatically reduce speed and avoid errors.

Servo Motor Control: Ensures precise movement of the traverse for neat and consistent coiling.

C. Automatic Coil Strapping Machine

Program Control: Automates coiling and strapping for seamless integration.

Adjustable Tension: Accommodates different wire coil sizes for secure strapping.

Strapping Capability: Secures coils at 3–6 places for stability during transport.

Includes a taper roll with lifting and lowering functions for guiding wires during the coiling process.

D. Automatic Wire Coil Unloading Machine

Safely and efficiently unloads coiled wire for further processing or packaging.

Designed for smooth integration with the coiling system, minimizing manual handling.

Advanced Features of the Automatic Wire Coiler

Safety and Reliability

Includes anti-collision features with a compression spring to protect against damage.

Emergency stop buttons and limit switches ensure safe operations.

Intelligent Control System

Features a touch-screen operation panel with speed adjustment and an emergency switch.

PLC system automates and optimizes coiling processes.

Alarm notifications for real-time issue detection.

Customizable and Flexible Design

Supports varying coil sizes with automatic positioning and tension adjustment.

Seamless integration with coiling and strapping machines.

High Efficiency and Precision

Fast and accurate coiling ensures consistent results.

Reduces material waste and minimizes errors during production.

Applications in the Steel Wire Industry

The Automatic Wire Coiler is perfect for industries requiring precise and efficient wire handling, including:

Metal Extrusions

Steel Wire Products

Lumber and Wooden Boards

Textile and Insulation Products

Why Choose FHOPE's Automatic Wire Coiler?

Advanced Technology: Ensures full automation for consistent and efficient wire handling.

Cost-Effective: Reduces labor costs and material waste, increasing overall profitability.

Comprehensive Support: FHOPE provides sales, service, and engineering expertise for a customized solution.

Durable and Reliable: Designed with high-quality materials to ensure longevity and reliability.

The FHOPE Automatic Wire Coiler is a game-changing solution for the steel wire industry, offering unmatched productivity, precision, and cost-effectiveness. With its advanced features and robust design, it is the ultimate tool for businesses looking to streamline operations and reduce costs.

Technical Features

| Feature | Description |

|---|---|

| Suitable for Wire Diameter | Customized |

| Maximum Speed | 200-800m/min |

| Center Height of Machine | 1000mm from the ground |

| Supply Voltage | 380/440 Vca, 60Hz |

| Coil Info | Customized |

| Speed per Hour | 40/hour (double head), 20/hour (one head) |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635