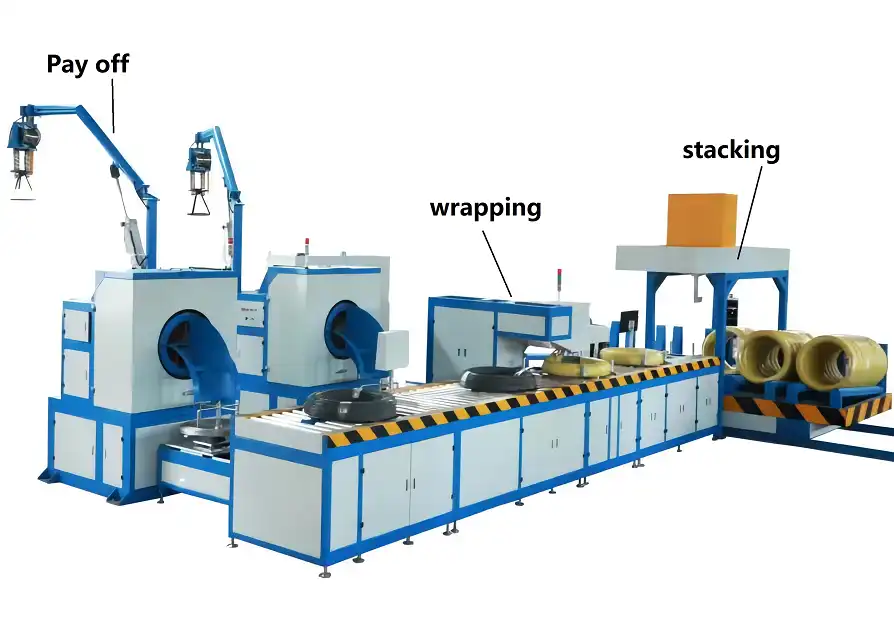

Automatic steel wire winding and binding machine

The Automatic Steel Wire Binding Machine is designed to wind and bind steel wire coils efficiently, incorporating an innovative elephant trunk-type winding mechanism. This unique feature addresses challenges like low coil weight and excessive wire joints in previous designs, making it a reliable solution for modern wire manufacturing.

Key Features

Innovative Winding Mechanism

Elephant trunk connecting plate enhances coil weight and reduces wire joints.

Eye-to-sky reel orientation ensures stable and efficient operation.

Efficient Binding System

Options for single or dual twisting devices for secure multi-point binding.

Uses steel wire as binding material, reducing costs while ensuring durability.

High Working Stability

Smooth operation supported by a torque motor (10kg/m).

Simple, robust structure for reliable and low-maintenance performance.

Special Features

Related video

An automatic steel wire winding and binding machine is a high-performance equipment designed to coil and bind steel wires with precision. It enhances efficiency by automating the process, ensuring consistent results and secure bundling. Ideal for industrial applications, it reduces labor costs and improves overall productivity.

Automatic Steel Wire Binding Machine: Innovative Solution for Wire Coil Winding and Binding

The Automatic Steel Wire Binding Machine is a cutting-edge innovation designed to efficiently wind, bind, and handle steel wire coils. Incorporating advanced features such as the elephant trunk-type winding mechanism, this machine addresses key challenges like increasing coil weight and minimizing wire joints, ensuring enhanced performance and reliability in wire manufacturing and packaging processes.

Core Features and Advantages

1. Elephant Trunk-Type Winding Mechanism

Unique Design:

Includes a frame structure and a reel arranged with an "eye-to-sky" orientation.

One end features a winding plate connected to a power mechanism for rotation, while the other end incorporates an elephant trunk connecting plate.

Key Benefits:

Allows for efficient winding of steel wire coils.

Increases finished coil weight and reduces wire joints, enhancing product quality and reducing waste.

Stable and Smooth Operation:

Ensures high working stability for improved production efficiency.

Simple and robust structure supports reliable long-term use.

2. Advanced Binding Capabilities

Versatile Binding Options:

Uses steel wire as the binding material, reducing binding costs.

Two binding solutions are available:

Two Twisting Devices: Bind one coil in two places simultaneously.

Single Twisting Device with Rotating Table: Bind one coil in two places efficiently.

Precision and Durability:

Ensures coils are securely bound to withstand storage and transportation demands.

Optimized for minimizing coil damage and improving overall handling.

3. Efficient Handling and Lifting Mechanism

Two Axial Movements:

Crane moves forward and backward, and lifts and lowers, allowing seamless coil transport.

Improved Safety and Efficiency:

Reduces manual handling efforts, enhancing safety and productivity in storage or manufacturing environments.

Basic Parameters of the Machine

Diameter of Winding Reel: φ560mm

Winding Speed: 360m/min

Wire Diameter: φ2–φ4mm

Weight of Wire Coil: 50–1000kg

Motor: 10kg/m torque motor

Key Advantages of the Machine

Innovative Design:

The elephant trunk connecting plate and eye-to-sky configuration make this machine a breakthrough in wire coil winding technology.

Improved Productivity:

High-speed winding (360m/min) and flexible binding options help businesses achieve cost savings and higher output.

Versatility:

Supports a wide range of coil weights (50–1000kg) and wire diameters (φ2–φ4mm).

Cost-Effective Binding:

Utilizes steel wire for binding, reducing overall material costs.

Safe and Reliable Operation:

Includes safety features and protocols to ensure smooth and secure operation.

Applications in the Wire Manufacturing Industry

This machine is ideal for industries requiring efficient winding, binding, and handling of steel wire coils, such as:

Steel Wire Production

Cable Manufacturing

Metal Coil Processing

Industrial Packaging Solutions

Operational and Safety Considerations

Proper Training:

Operators must be trained to handle the machine effectively and safely.

Routine Maintenance:

Regular inspections of the winding mechanism, binding devices, and handling equipment are essential for long-term reliability.

Adherence to Safety Protocols:

Follow recommended guidelines for lifting, binding, and moving wire coils to ensure the safety of workers and equipment.

Why Choose the Automatic Steel Wire Binding Machine?

Innovative Technology: Revolutionizes wire coil production with advanced features like the elephant trunk mechanism.

Enhanced Productivity: Increases coil weight while reducing wire joints, minimizing waste and maximizing output.

Cost-Effective Solution: Reduces binding material expenses and operational costs.

Reliable Performance: Delivers stable and efficient operation for long-term use.

Improved Safety: Includes robust safety features for handling and transport.

By investing in this machine, businesses can streamline their wire coil production and packaging processes, ensuring higher efficiency, cost savings, and enhanced product quality.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635