Mold Flipper for 20T

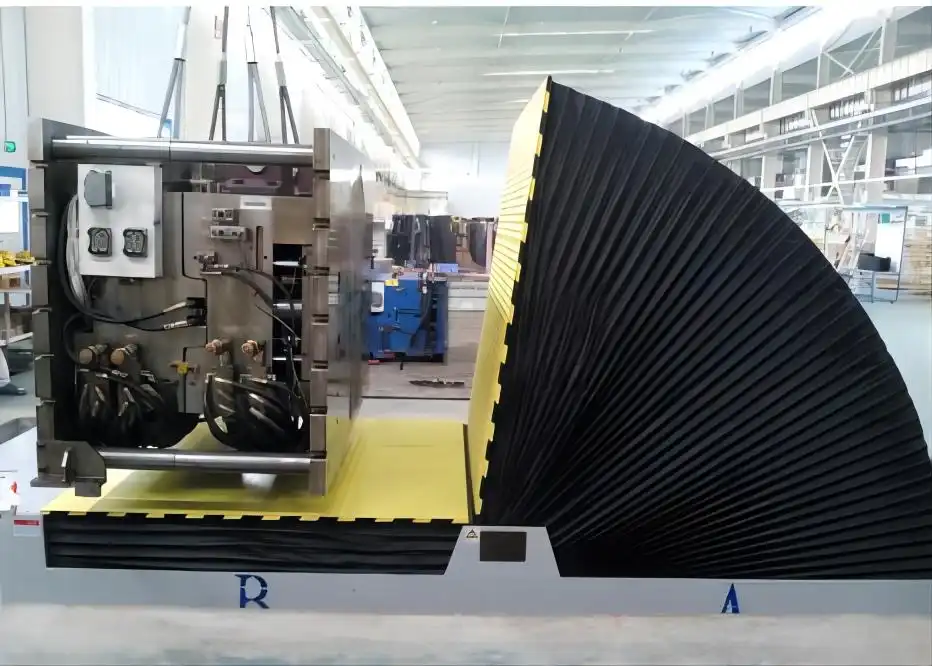

The Mold Flipper Table for 20T is a heavy-duty solution designed for efficient handling of molds weighing up to 20 tons. Its durable steel construction, hydraulic system, and 180-degree flipping capability ensure seamless operation, reduced downtime, and enhanced productivity in industrial settings.

Model Type: FPMT-20

Maximum Load Capacity: 20 Tons

Table Dimensions (L × W × H): 3800 × 1500 × 460 mm

Motor Power: 7.5 kW

Maximum Rotation Angle: 180 Degrees

Special Features

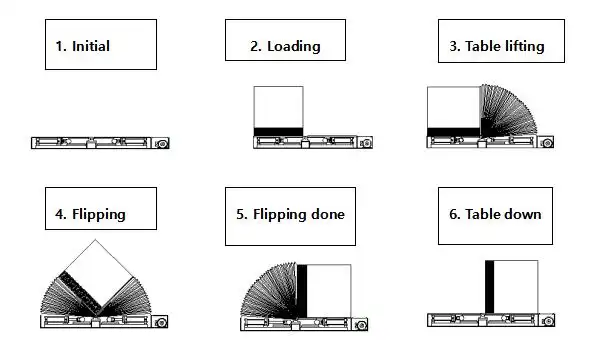

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

The Mold Flipper for 20T is a robust industrial solution designed to safely and efficiently rotate heavy molds weighing up to 20 tons. With precision engineering, it enhances workplace safety, reduces manual handling risks, and streamlines operations. Its durable construction and user-friendly controls make it ideal for demanding manufacturing environments.

Mold Flipper Table for 20T

The Mold Flipper Table for 20T is a high-performance industrial solution designed to handle molds weighing up to 20 tons with ease. Built for large-scale operations, this equipment ensures seamless workflow in injection molding processes. Its durable construction and precision engineering significantly reduce downtime while improving productivity by enabling fast and accurate mold repositioning in demanding industrial settings.

Features and Benefits

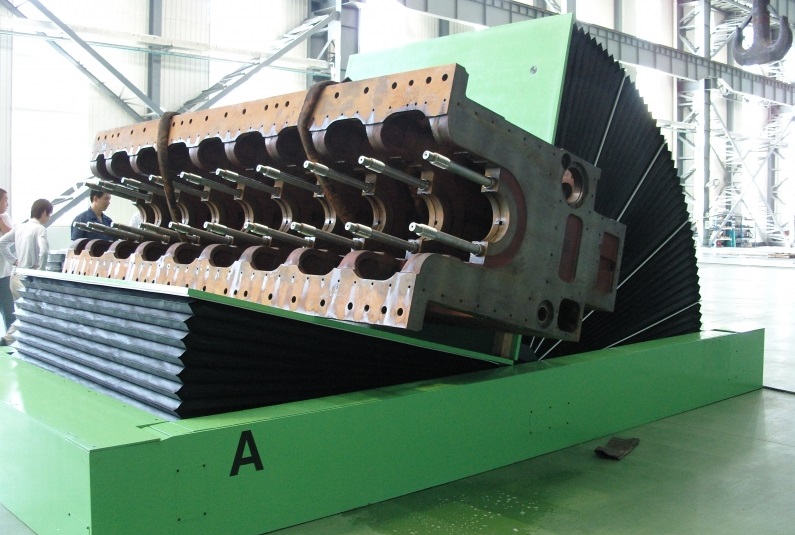

Heavy-Duty Construction: Crafted from high-grade industrial steel to ensure long-lasting durability and reliability.

Smooth Operation: Equipped with a hydraulic power system for seamless and efficient flipping of heavy molds.

Productivity Boost: Fast flipping speed reduces downtime, enabling continuous operations and higher efficiency.

Full Rotational Capability: Supports 180-degree rotation, making it versatile for various mold flipping requirements.

Compact Design: Optimized dimensions ensure space-saving functionality while handling heavy loads effectively.

Technical Specifications

| Specification | Details |

|---|---|

| Model Type | FPMT-20 |

| Material Construction | High-grade industrial steel |

| Power Source | Electric-hydraulic power system |

| Operational Mechanism | Hydraulic system for smooth and efficient flipping |

| Flipping Speed | Designed for quick flips, reducing downtime |

| Maximum Load Capacity | 20 tons (20,000 kg) |

| Table Length | 3,800 mm |

| Table Width | 1,500 mm |

| Table Height | 460 mm |

| Motor Power | 7.5 kW |

| Total Machine Weight | 20 tons (20,000 kg) |

| Hydraulic Oil Capacity | 15 liters |

| Maximum Rotation Angle | 180 degrees (full flipping capability) |

Advantages of the Mold Flipper Table

Enhanced Safety: The hydraulic system ensures safe handling of heavy molds, minimizing risks for operators.

Time Efficiency: Quick flipping operations lead to shorter production cycles and better overall efficiency.

Robust Performance: With a maximum load capacity of 20 tons, this table is built to handle even the most demanding tasks.

User-Friendly Design: Intuitive controls and a compact footprint make it easy to integrate into existing workflows.

Versatility: Its ability to rotate molds a full 180 degrees makes it suitable for various industrial applications.

This mold flipper is the ideal choice for large-scale injection molding operations that demand precision, efficiency, and safety. It is an essential tool for improving production efficiency while ensuring reliability in handling heavy molds.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635