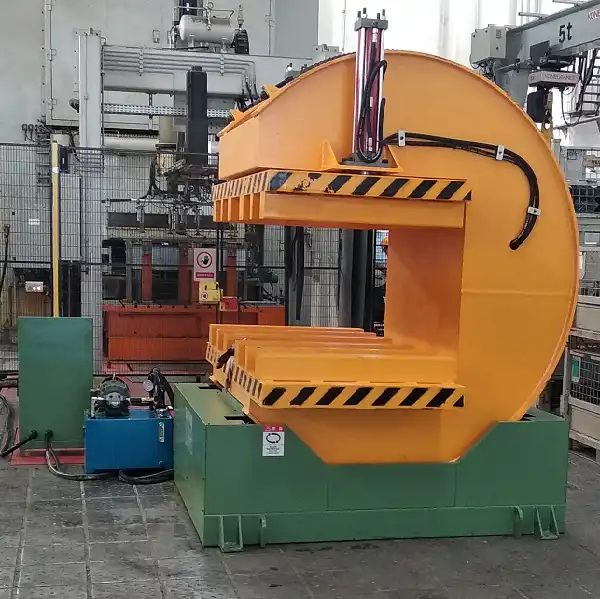

Load Inverter

FHOPE Load Inverters are designed for the safe and efficient rotation of heavy and bulky loads, providing customizable solutions for diverse industries. With durable construction and advanced control systems, these machines enhance productivity while ensuring operational safety.

Key Features:

Robust Design: Built to handle demanding industrial conditions.

Inverter-Controlled Speed: Allows precise adjustment for varying load sizes.

Safety Mechanisms: Includes emergency stop buttons and position locking.

Customizable Options: Tailored to meet specific industry needs.

CE & ISO Certified: Adheres to international safety and quality standards.

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

A Load Inverter is a versatile machine engineered to rotate or flip heavy loads, such as pallets or industrial components, for seamless handling and operational flexibility. It boosts efficiency, enhances safety, and reduces manual effort, making it a critical tool in logistics, manufacturing, and material handling industries.

FHOPE Load Inverters: Customized Solutions for Efficient Load Rotation

FHOPE’s Load Inverters are designed to handle a wide range of heavy and bulky loads, providing a versatile and efficient solution for various industries. These machines can be customized to meet specific operational needs, offering a stable and durable structure that enhances productivity and safety during load rotation. Featuring a switch control panel and inverters for speed adjustment, FHOPE's load inverters are ideal for industries looking to improve their production processes and streamline workflows.

Key Features of FHOPE Load Inverters

Stable and Durable Structure

FHOPE's load inverters are built with a robust structure, ensuring long-lasting performance even under demanding industrial conditions. The design prioritizes both stability and durability, making these machines ideal for handling heavy loads across multiple industries.

Switch Control Panel for Easy Operation

The load inverters are equipped with a switch control panel that provides operators with an intuitive interface for managing machine functions. This control system allows for easy and efficient operation, minimizing the risk of operational errors.

Inverter-Controlled Speed Adjustment

FHOPE load inverters are fitted with inverters that allow operators to adjust the running speed of the machine. This feature is crucial for accommodating different types of loads with varying weights and sizes, ensuring safe and precise rotation every time.

Safety Features for Added Protection

Safety is a top priority in industrial operations, and FHOPE’s load inverters come equipped with key safety features to protect both operators and equipment. These include emergency stop buttons and position locking systems, which enable the machine to stop at any time during operation for added safety.

Applications of FHOPE Load Inverters

FHOPE’s load inverters are versatile machines suitable for a wide array of industries that require the rotation of heavy and bulky loads. Some of the key industries where these machines are commonly used include:

Cable Industry

Sheet Metal Industry

Automotive Industry

Aerospace Industry

Pharmaceutical Industry

Food and Beverage Industry

Textile Industry

Logistics and Warehousing Industry

Construction Industry

Packaging Industry

Paper Industry

Plastic Industry

Woodworking Industry

Chemical Industry

These industries benefit from the precision and efficiency offered by FHOPE’s load inverters, enhancing operational productivity and ensuring the safe handling of heavy materials.

FPCT Series Tilter: Advanced Solutions for Safe Load Rotation

The FPCT series tilter is a versatile and efficient machine designed to safely rotate loads through 180 degrees. This machine is ideal for industries such as steel, wire, aluminum, copper, mold, and wheel spool production. The FPCT series tilter is easy to operate and can be used for loading and unloading with a forklift or other trucks.

Optional Base Rotating Drive System

For added convenience, the FPCT series tilter is equipped with an optional base rotating drive system, which allows it to load and unload from the same side. This eliminates the need for extra forklift movement, improving efficiency and reducing the complexity of the loading and unloading process.

Customization for Specific Application Needs

FHOPE offers customization options for the FPCT series tilter, ensuring that the machine meets the specific needs and goals of various industries. This level of customization ensures that each tilter delivers the precision and efficiency required for optimal production performance.

Basic Features of FHOPE Load Inverters

CE and ISO Certification: Ensuring safety and quality assurance, all FHOPE load inverters are CE and ISO certified.

Customizable Options: Tailored solutions are available to meet the specific needs of various industries.

Durable Materials: Made from high-quality materials, FHOPE load inverters are built for long-lasting performance and reliability.

Maintenance and Repair Services: FHOPE provides maintenance and repair services to ensure the continued optimal functioning of the machines.

Technical Support: The experienced and knowledgeable technical support team is available to assist with installation, operation, and troubleshooting.

Cost-Effective Solution: FHOPE’s load inverters offer a cost-effective solution for enhancing efficiency and productivity across various industries.

Conclusion

FHOPE's Load Inverters and FPCT Series Tilters offer efficient and customizable solutions for industries requiring the safe and reliable rotation of heavy and bulky loads. With robust construction, precision control features, and an emphasis on safety, these machines significantly enhance productivity while reducing manual labor. Whether in the cable, automotive, pharmaceutical, or any other industry, FHOPE’s tilter equipment provides an effective way to improve production processes, streamline workflows, and ensure the safe handling of materials.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635