Spool Drum Tilter

The Spool Turnover Machine, also known as a Roller Turnover Machine, is a reliable solution for rotating and handling heavy spools, coils, and similar objects. Designed for industries like cable production, module handling, and coil rotation, it enhances productivity while reducing manual labor through safe and efficient operation.

Key Features:

Customizable Design: Tailored for different spool sizes, weights, and materials.

Hydraulic Drive System: Provides smooth and precise operation.

Integrated Conveyor System: Streamlines material handling for improved workflow.

Adjustable Tilting Angles: Offers flexibility for various operations like wrapping or rotation.

Safety Mechanisms: Equipped with emergency stop buttons, limit switches, and interlock systems.

Automation Integration: Compatible with other systems for enhanced efficiency.

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

Spool tilter machine is commonly used in the cable industry to rotate objects. It uses two special chain drives and is equipped with displacement restrictors for safety. The working table can tilt the load from 0-90 degrees, providing safe operation for wrapping. The machine can be customized to meet specific requirements.

Spool Turnover Machine: Versatile Solutions for Efficient Rotation and Handling

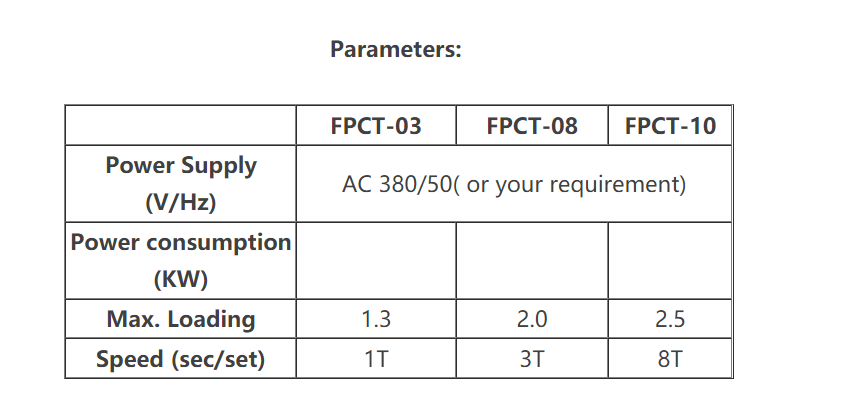

The spool turnover machine, also known as a roller turnover machine, is an essential piece of equipment used primarily in the cable industry for turning and rotating heavy spools, coils, and other objects. Its versatility extends across various industries, such as module ending, coil rotation, and subversion, offering customized solutions for different handling needs. By enabling the safe and efficient rotation of materials, the spool turnover machine improves productivity and reduces manual labor.

Key Features of the Spool Turnover Machine

Customizable to Meet Client Requirements

FHOPE’s spool turnover machines are highly customizable to meet the specific needs of different clients and industries. The design can be tailored to handle various types of spools, coils, and modules, including those made from steel, aluminum, or other materials. Customization ensures that the machine operates effectively for different product sizes, shapes, and weights, improving its versatility and suitability for diverse applications.

Hydraulic Drive System for Smooth Operation

One of the standout features of the spool turnover machine is the hydraulic drive system, which provides smooth and powerful operation. The hydraulic system ensures efficient and controlled movement, offering precise tilting and rotation of the load. This smooth operation reduces strain on both the machine and the material, ensuring high-performance results during continuous use.

Integrated Conveyor System

To further streamline material handling, the spool turnover machine can be equipped with an integrated conveyor system. This allows for seamless transport of materials into and out of the machine, improving efficiency in the production process. The conveyor system helps reduce manual handling and ensures that materials are moved safely and precisely.

Adjustable Tilting Angle and Multiple Positions

The spool turnover machine is designed with flexibility in mind, offering adjustable tilting angles and the ability to switch between multiple tilting positions. This feature allows the machine to handle a wide range of materials and operations, such as wrapping, subversion, and rotation. By adjusting the tilting angle, operators can ensure the right positioning of the load for different tasks, optimizing the machine’s performance.

Safety Features for Operator Protection

Safety is a top priority when handling heavy loads. FHOPE’s spool turnover machines come equipped with various safety features, including:

Emergency Stop Button: Quickly halts the machine in case of an emergency, protecting operators and preventing damage to materials.

Limit Switch: Prevents the machine from exceeding safe operational limits, reducing the risk of accidents.

Interlock System: Ensures that the machine cannot be operated unless all safety protocols are in place, further enhancing the overall safety of the operation.

Integration with Other Equipment or Automation Systems

For enhanced efficiency and automation, the spool turnover machine can be integrated with other equipment or automation systems. This integration allows for smoother workflows, as the machine can be part of a larger production system that operates automatically. Automation further reduces the need for manual intervention, saving time and increasing overall productivity.

Working Table Design and Customization

Tilting Functionality for Safe and Efficient Handling

The working table of the spool turnover machine is a crucial component designed to handle a wide range of products. It can tilt loads from 0° to 90°, providing flexibility in handling materials with varying shapes and sizes. This tilting function allows the machine to perform a variety of operations, such as rotating, wrapping, or subverting products safely and effectively.

Durable and Customizable Table Materials

The working table can be made from a variety of materials, including steel, aluminum, or other robust materials, depending on the product’s weight and dimensions. Additionally, the table can be coated with anti-slip or anti-corrosion materials to protect the product being handled and increase the longevity of the machine. These materials are selected to suit the specific needs of the client and ensure the table's durability under different conditions.

Customizable Design for Specific Requirements

FHOPE’s spool turnover machines are fully customizable, allowing clients to specify the exact requirements for the working table. Whether it's for handling specific materials or performing certain operations, the design and materials of the table can be adapted to meet the customer’s exact needs. This customization ensures that the machine can perform a range of tasks efficiently while maintaining the highest safety standards.

Conclusion

FHOPE’s Spool Turnover Machine is an efficient, customizable, and reliable solution for industries that require the rotation and handling of heavy spools, coils, and other objects. With its hydraulic drive system, adjustable tilting functionality, and safety features, this machine ensures smooth, controlled, and safe operation, enhancing productivity across various industries. The ability to integrate with other equipment or automation systems further boosts operational efficiency, making it an ideal choice for industries such as cable production, module handling, and coil rotation. The customizable design of the working table and additional features ensures that each machine meets the specific needs of the client, offering optimal performance for every application.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635