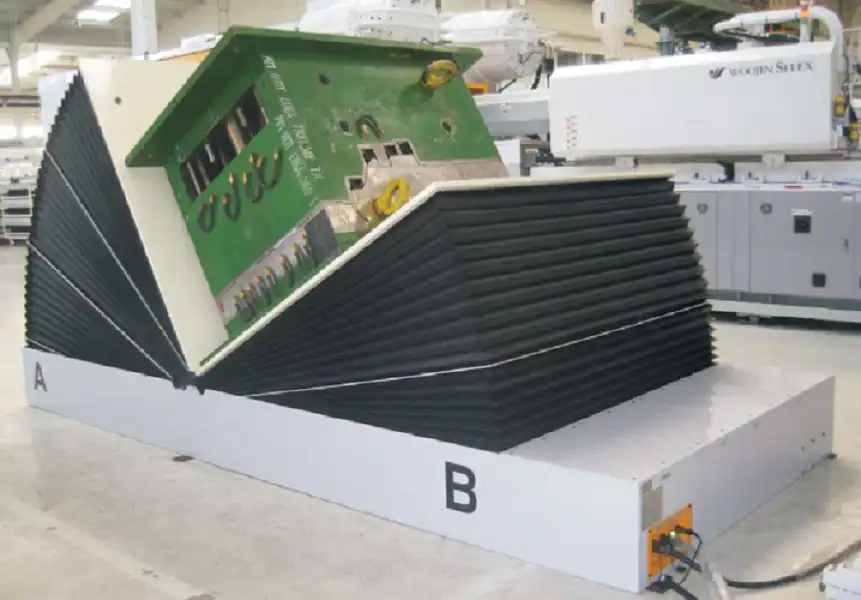

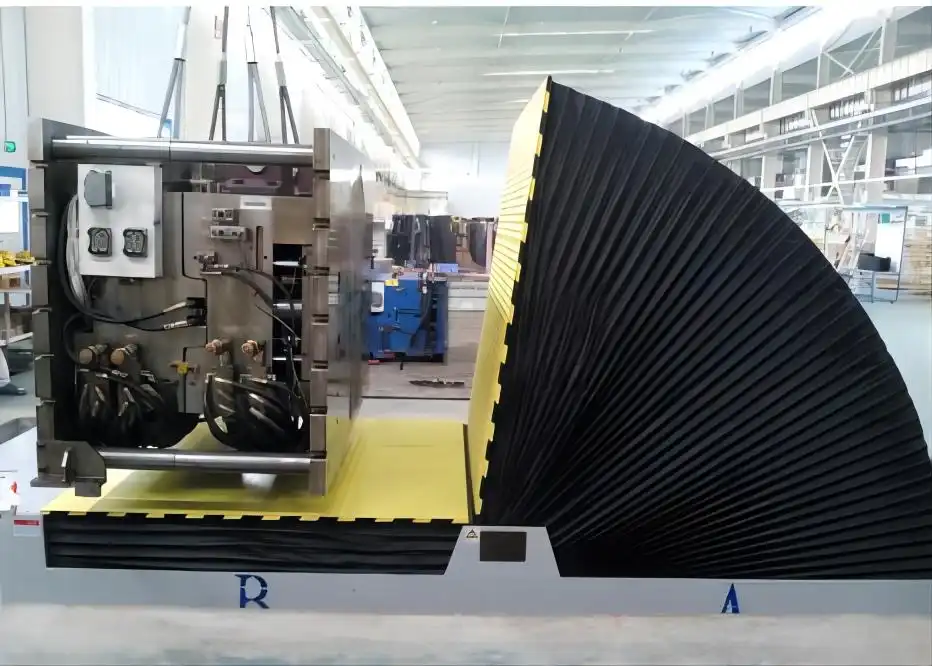

180 Degree Mold Upender 20T

The 180 Degree Mold Upender 20T is designed for heavy-duty industrial applications, offering the ability to safely rotate molds up to 20 tons. This hydraulic-powered equipment enhances efficiency and safety in manufacturing, featuring precision control, robust construction, and integrated safety features. Whether operated manually or through an automated interface, it simplifies complex tasks, reduces downtime, and ensures smooth production workflows.

Model Type: FPMT-20

Maximum Load Capacity: 20 tons (20,000 kg)

Motor Power: 7.5 kW

Table Dimensions: 3500 mm × 2500 mm × 550 mm

Maximum Rotation Angle: 90 degrees

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

The 180 Degree Mold Upender 20T is a heavy-duty machine designed to safely and efficiently rotate molds or materials up to 20 tons. Its advanced design ensures smooth operation, reducing risks and improving workflow in industrial settings. Ideal for manufacturing environments requiring precise and reliable mold handling solutions.

Die Flipper | 180 Degree Mold Upender 20T

The 180 Degree Mold Upender 20T is a robust solution designed to handle demanding industrial tasks. Capable of efficiently rotating molds up to 20 tons, this equipment prioritizes safety, efficiency, and precision. Its ergonomic design and advanced features enhance manufacturing workflows, ensuring seamless operations while maintaining high product quality.

This upender is an indispensable tool for industries requiring safe and controlled mold handling. Its ability to deliver smooth and precise rotations significantly reduces the risk of workplace accidents, offering peace of mind to operators. With its high load capacity and advanced hydraulic system, the FPMT-20 model is engineered to meet the rigorous demands of modern manufacturing.

Key Features and Benefits

Efficient Mold Handling: Simplifies the process of rotating heavy molds, enhancing operational speed.

Enhanced Safety: Equipped with integrated safety locks and emergency stop functions to protect operators.

Versatile Control Options: Choose between manual or automated control interfaces for optimal flexibility.

Durable Construction: Built to handle heavy-duty operations with a stable base requirement.

Precision Engineering: Ensures controlled movements, reducing wear on molds and improving product quality.

Technical Specifications

| Feature | Details |

|---|---|

| Power Source | Hydraulic options available |

| Control System | Manual or Automated control interfaces |

| Safety Features | Integrated safety locks, emergency stop functions |

| Installation Requirements | Requires a stable and level base |

| Model Type | FPMT-20 |

| Table Dimensions | Length: 3500 mm Width: 2500 mm Height: 550 mm |

| Maximum Load Capacity | 20 tons (20,000 kg) |

| Motor Power | 7.5 kW |

| Total Machine Weight | 20 tons (20,000 kg) |

| Hydraulic Oil Capacity | 15 liters |

| Maximum Rotation Angle | 90 degrees (full flipping capability) |

Why Choose the 180 Degree Mold Upender 20T?

Operational Efficiency: This tool optimizes production processes, reducing manual labor and minimizing downtime.

Safety Assurance: Designed with operator protection in mind, featuring multiple safety mechanisms.

Durability and Reliability: Built with high-quality materials to withstand the rigors of industrial environments.

Flexibility: Offers a choice of manual or automated controls to adapt to varying operational needs.

Ease of Installation: Requires only a stable and level base, simplifying setup.

Applications

The 180 Degree Mold Upender 20T is ideal for:

Automotive manufacturing

Heavy machinery production

Plastic molding industries

Metal fabrication units

Aerospace component manufacturing

This versatile tool enhances productivity across industries by delivering a reliable solution for heavy-load mold handling. Its precision and durability make it a worthwhile investment for any industrial operation.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635