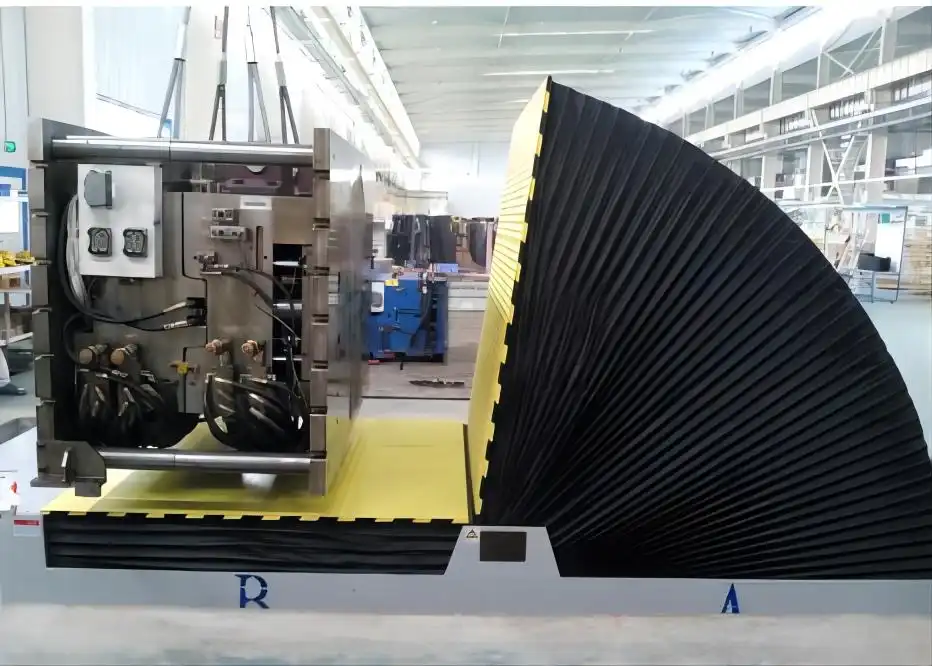

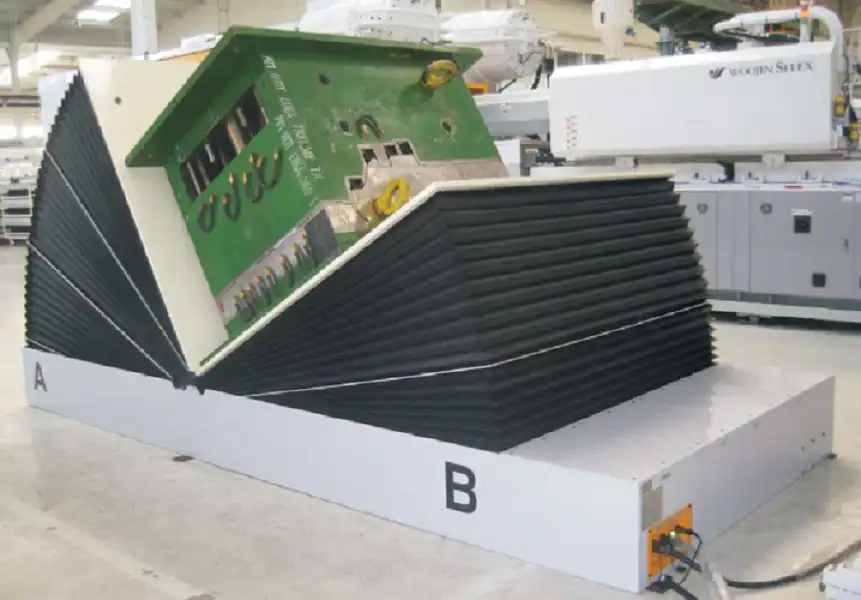

Mold flipper

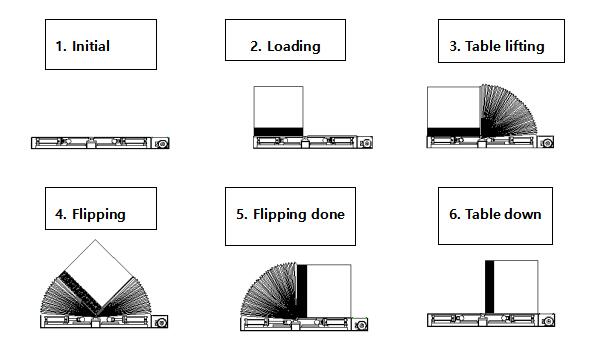

Flipper lift tables are versatile machines designed for various industrial applications, including mold processing, die handling, engine assembly, and material inversion. They provide safe and efficient solutions for flipping molds and dies by 90 to 180 degrees without causing damage.

Key Features

Applications: Mold and die flipping, engine assembly, roll material inversion, and more.

Heavy-Duty Handling: Supports loads from 1 to 60 tons with smooth hydraulic operation.

Customization: Adjustable payloads, deck sizes, hydraulic components, and tilt speeds to meet specific requirements.

Efficiency: Eliminates reliance on overhead cranes for safer and faster operations.

Quality Solutions: Fhope offers certified, tailored equipment to support modern industrial demands.

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

The Flipper Lift Table is a machine designed for flipping molding boxes (for mating response to drag or for sand shake off) with a safe and efficient operation. It can handle any size portion from 100 LBS to over 100 tons, simply by pressing a button. This makes it very versatile and useful in many industrial applications.

Exploring the Versatility of Flipper Lift Tables in Industrial Applications

Flipper lift tables are invaluable machines in industrial settings, offering safe and efficient handling of molds, dies, and other heavy components. Their ability to handle a wide range of tasks makes them an essential tool for various manufacturing and processing industries.

Key Applications of Flipper Lift Tables

Mold Processing and Assembly

Ideal for handling molds during manufacturing, ensuring precision and safety during processing and assembly.

Mold Plug-In Replacement and Movement

Facilitates the easy replacement and movement of mold plug-ins, reducing manual effort and risks.

Engine Processing and Assembly

Supports the machining and assembly of engines, making it a versatile solution for automotive and machinery industries.

Material Inversion

Efficiently inverts roll materials and other heavy items, saving time and reducing labor requirements.

Injection Die and Mold Handling

Ensures the secure handling and flipping of injection dies and molds, preventing damage and improving workflow.

Fhope: Industry Leader in Heavy-Duty Equipment

Fhope specializes in designing and manufacturing hydraulic-powered solutions for safely handling molds and dies weighing between 1 to 60 tons. Their innovative equipment ensures that molds are turned, rotated, and tilted without impact or damage, meeting the demanding needs of modern industrial environments.

Hydraulic System Advantages:

Enables smooth turning and flipping of molds and dies by 90 to 180 degrees, ensuring controlled operations.

Versatility in Application:

The same equipment can handle both mold flipping and die flipping, making it a cost-effective and flexible solution for industrial processes.

Modern Solutions for Evolving Industries

The Mold Flipper and Turnover Machine addresses the growing need for efficient mold and die handling in today’s metal processing industry. Key benefits include:

Enhanced Safety:

Eliminates the need for operators to rely on overhead cranes, reducing risks during operation.

Customizable Features:

Fhope offers customization options for payload capacities, loading deck sizes, working table dimensions, hydraulic components, covers, and tilt speeds.

Global Reach:

Fhope’s flat-panel upender machines are used by industries worldwide, tailored to meet specific operational requirements.

Why Choose a Flipper Lift Table?

Flipper lift tables are more than just mold handling tools—they are versatile, efficient, and essential for ensuring workplace safety and operational productivity. With Fhope’s expertise in heavy-duty machinery, businesses gain access to customizable, reliable, and industry-certified equipment designed to meet the challenges of modern industrial processes.

Technical Specifications

| Parameter | Details |

|---|---|

| Operational Mechanism | Hydraulic drive system for smooth and efficient flipping |

| Power Source | Electric-hydraulic power system |

| Safety Features | Safety interlocks and emergency stop functionalities |

| Flipping Speed | High-speed flipping to minimize downtime |

| Model Type | FPMT-40 |

| Table Dimensions | Length: 4500 mm, Width: 2400 mm, Height: 500 mm |

| Maximum Load Capacity | 40 tons (40,000 kg) |

| Motor Power | 7.5 kW |

| Machine Weight | 40 tons (40,000 kg) |

| Hydraulic Oil Capacity | 15 liters |

| Maximum Rotation Angle | 180 degrees (full flipping capability) |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635