How We Help You Find the Best Solution for a Mold Flipper

Choosing the right equipment for your production line can feel overwhelming. With numerous machines to choose from and countless factors to consider, it’s crucial to partner with a supplier who truly understands your needs. At FHOPEPACK, we not only offer cutting-edge mold flippers but also provide guidance to ensure the solution we offer aligns perfectly with your business goals.

Whether you’re handling large, complex molds or small and precise components, our mold flippers are designed to help you enhance your productivity, reduce labor costs, and ensure a safer working environment. But we go beyond just selling equipment – we aim to equip you with the tools and knowledge needed to make informed decisions and achieve long-term success.

Our approach is comprehensive: from understanding your specific production challenges to offering tailored solutions, our team works hand in hand with you every step of the way.

1. What unique features of our Mold Flipper address your production challenges?

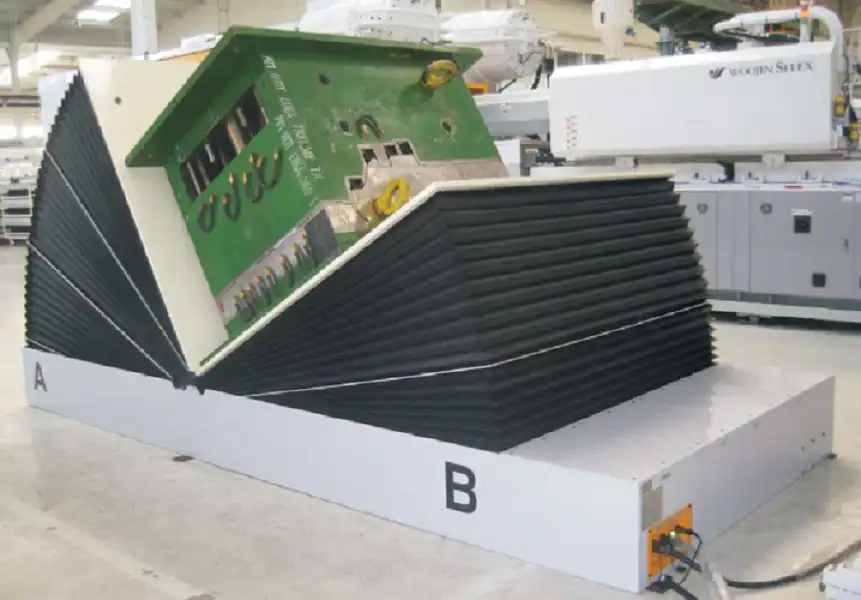

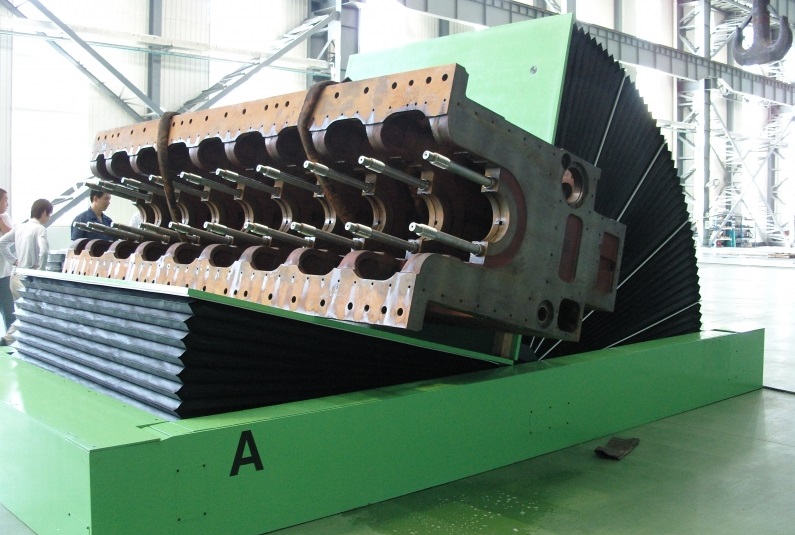

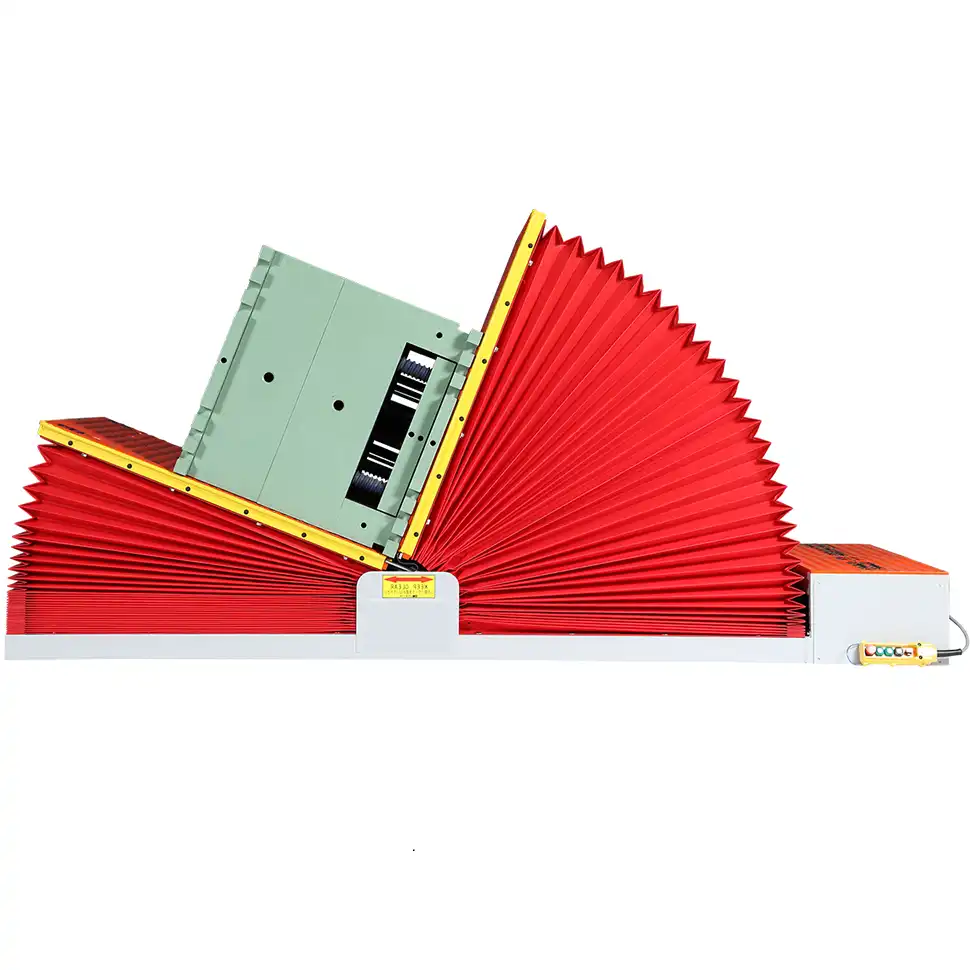

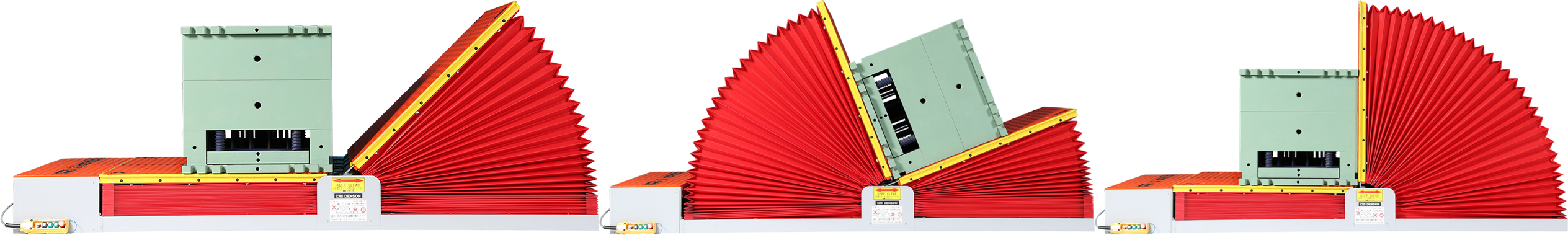

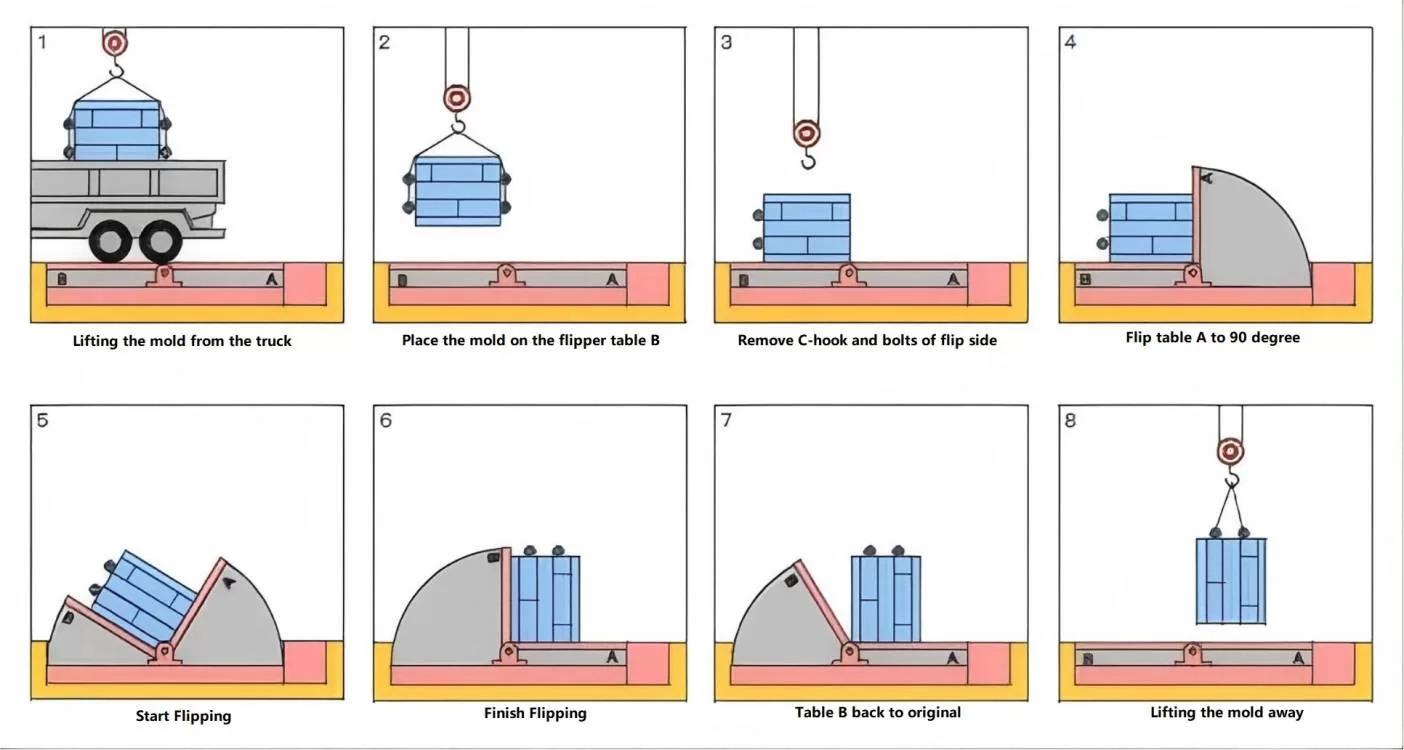

When it comes to lifting and flipping heavy molds, precision and efficiency are paramount. At FHOPEPACK, we’ve engineered our Mold Flippers to provide maximum reliability and performance, addressing common production challenges with ease. From improving handling efficiency to ensuring the safety of your operators, our Mold Flippers are designed to optimize your operations.

Built for Durability and Precision

Our Mold Flippers are constructed using high-quality materials and advanced engineering techniques. They are designed to handle molds of various shapes and sizes, from the lightest to the heaviest, without compromising performance. Equipped with precision controls, our Mold Flippers can rotate and position molds with high accuracy, minimizing the risk of errors or damage.

Key Features

Heavy-duty Construction: Capable of handling molds weighing up to 30 tons.

Precise Rotation Mechanism: Ensures that molds are flipped and positioned exactly as needed.

Energy-efficient Hydraulic System: Reduces energy consumption, making operations more cost-effective.

Safety Features: Equipped with multiple safety sensors and an emergency stop function for operator safety.

Features at a Glance:

| Feature | Benefit |

|---|---|

| Heavy-duty Construction | Supports high-weight molds without strain |

| Precise Rotation Mechanism | Ensures accurate flipping and placement |

| Energy-efficient System | Reduces energy costs |

| Safety Sensors | Enhances operator safety and operational reliability |

With these features, our Mold Flippers address several common production challenges, including the safe handling of large and heavy molds, minimizing downtime, and maximizing efficiency. By providing a reliable, precise solution, we help you reduce operational risks and improve the overall workflow.

2. How do our years of expertise and respected reputation ensure a successful working relationship?

Choosing the right equipment supplier goes beyond just the machines; it’s about building a partnership that will help your business thrive. At FHOPEPACK, we combine decades of experience, a deep understanding of industrial packaging, and a track record of success to ensure that our mold flipping solutions are the perfect fit for your production needs.

Experience You Can Trust

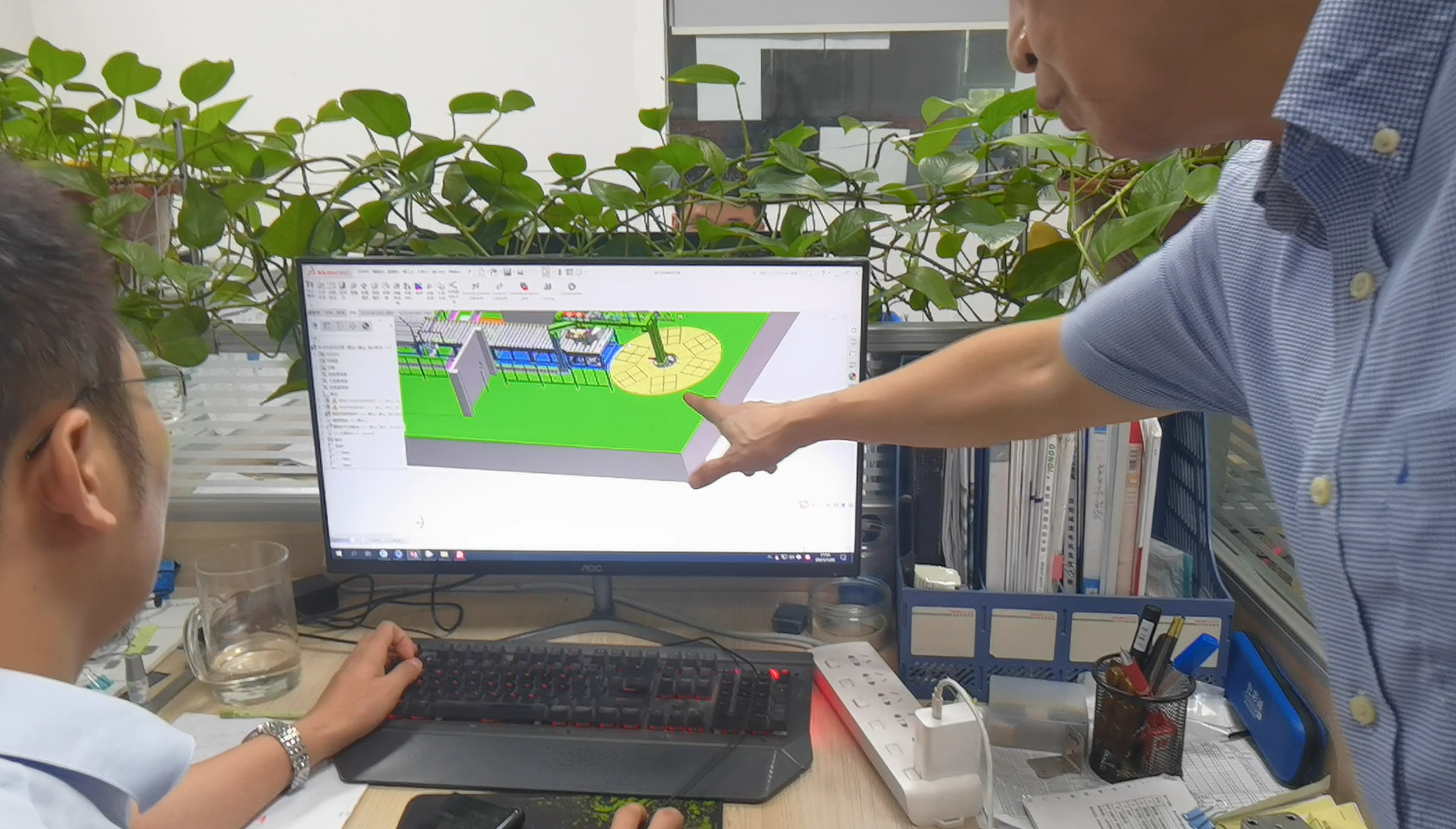

With over 15 years of experience in the field, our team is equipped to solve even the most complex challenges in mold handling. We don’t just sell equipment – we consult, design, and deliver solutions tailored to the unique demands of your production line. Our technical expertise spans multiple industries, including automotive and construction, ensuring that we understand the intricacies of mold handling and the specific requirements of your production environment.

A Reputation Built on Excellence

Our reputation as a trusted supplier is built on years of delivering high-quality products and exceptional customer service. We work closely with our clients from initial consultation to after-sales support, ensuring that our solutions meet and exceed expectations. Our team’s in-depth knowledge, combined with our focus on continuous improvement, means that we are always at the forefront of industry innovations.

Key Benefits of Our Expertise:

Tailored Solutions: Our engineers work with you to understand your exact needs, ensuring that the mold flipper we provide will integrate seamlessly into your production workflow.

Proven Success: Our mold flippers have been used successfully by clients across various sectors, demonstrating their effectiveness in enhancing productivity and improving safety.

Industry Knowledge: Our team’s expertise in both mold handling and packaging technology means we can anticipate and address potential challenges before they arise.

By choosing FHOPEPACK, you’re not just investing in a machine – you’re partnering with a company that has a solid reputation for reliability and excellence. Our goal is to build lasting relationships by delivering consistent, high-quality solutions that help you achieve your production goals with confidence.

3. How do we provide clear cost information to assist in confidently calculating ROI?

Cost is always a significant consideration when choosing new equipment, and we understand that you need transparency and clarity to make informed decisions. At FHOPEPACK, we believe in providing clear, detailed cost breakdowns that enable you to calculate ROI with confidence.

Transparent Pricing Model

Our pricing structure is designed to be straightforward, with no hidden costs or surprises. We offer detailed quotes that break down the cost of each component of the mold flipper, including production, delivery, installation, and any additional services. This transparency ensures that you can accurately predict the total investment required for your new equipment.

ROI Calculation Made Easy

When considering new equipment, it’s essential to understand the return on investment (ROI) it will generate. Our team works with you to calculate the expected ROI, considering factors like increased productivity, labor savings, and the reduction in mold damage. We take into account the full lifecycle cost of the machine, including energy consumption, maintenance, and long-term durability, helping you make an informed decision about your investment.

Cost Breakdown Example:

| Component | Estimated Cost |

|---|---|

| Mold Flipper Base Unit | $15,000 |

| Installation & Commissioning | $2,000 |

| Maintenance (Annual) | $1,500 |

| Energy Savings (Annual) | $2,000 |

By providing a clear breakdown and helping you calculate ROI, we ensure that you can make a confident decision based on solid data. Our goal is to help you not only choose the right machine but also maximize the value of your investment.

This transparent approach allows you to evaluate all costs involved and ensures that you can confidently assess how quickly you will see returns on your new mold flipper.

4. How do our reliable after-sales services contribute to the smooth functioning of your processes?

At FHOPEPACK, we believe that delivering a high-quality mold flipper is only the beginning of our partnership with you. Our after-sales services are designed to ensure the continued smooth operation of your equipment, minimizing downtime and maximizing productivity.

Comprehensive After-Sales Support

Our commitment to your success extends well beyond the sale. From the moment your mold flipper is delivered and installed, we offer comprehensive after-sales services to ensure it runs smoothly and efficiently. We provide both online troubleshooting support and on-site assistance, ensuring that you can access the help you need, when you need it.

Ongoing Maintenance and Technical Assistance

In addition to our delivery and installation services, we offer ongoing maintenance packages tailored to your needs. Regular maintenance not only prolongs the life of your equipment but also helps prevent unexpected issues that could disrupt your production schedule. Our technical support team is available to address any concerns, whether through remote diagnostics or on-site visits if necessary. This level of support helps you stay focused on your core operations, while we handle the maintenance of your machinery.

Key After-Sales Services:

Online Troubleshooting: Access to real-time support via phone or video call for troubleshooting and quick resolution of minor issues.

On-Site Commissioning: Our experienced engineers will visit your site to ensure the proper setup and commissioning of your mold flipper, ensuring it’s ready for seamless integration into your production process.

Annual Maintenance Plans: We offer cost-effective maintenance packages to keep your machine in optimal condition, preventing potential issues before they become costly problems.

Why Our After-Sales Services Matter:

The real value of a machine lies not just in its initial setup but in how it performs over time. Our after-sales support is designed to provide peace of mind and protect your investment. By maintaining close contact and offering proactive services, we ensure that your mold flipper stays productive, reliable, and efficient throughout its lifecycle.

5. Why is exceeding safety and compliance standards a key focus in the design of our Mold flipper?

Safety is a top priority when it comes to industrial machinery. At FHOPEPACK, we ensure that every mold flipper we design is built with the highest safety standards in mind. We understand that any compromise in safety can lead to costly accidents, downtime, and regulatory issues. That’s why we’ve designed our mold flippers to exceed industry safety and compliance standards.

Industry-Leading Safety Features

Our mold flippers come equipped with advanced safety features to protect both your workers and the equipment. These include safety fences, light beams, and sensors that help detect potential hazards and automatically stop the machine if necessary. These features work in conjunction with our design to ensure that your team can operate the equipment without fear of accidents.

Compliance with International Standards

All of our mold flippers are designed to meet or exceed international safety and regulatory standards. This includes compliance with OSHA regulations, CE certification, and other relevant safety codes. By adhering to these standards, we ensure that our machines provide a safe working environment while keeping your business in compliance with the law.

Key Safety Features:

Safety Fences: Enclosed barriers that prevent workers from coming into direct contact with moving parts.

Light Beams and Sensors: Detect objects or personnel in the danger zone and automatically stop the machine to prevent accidents.

Emergency Stop Buttons: Easily accessible buttons that can halt the machine in case of emergencies.

Safety is not just a requirement; it’s a fundamental aspect of our product design. Our mold flippers are built to protect both your people and your production line, ensuring a safe and compliant workplace. When you invest in FHOPEPACK, you’re investing in the safety and security of your operations.

6. How do we equip you with training and technical support for a seamless transition?

When you invest in a mold flipper, the transition to using it effectively should be as smooth as possible. That’s why FHOPEPACK places a strong emphasis on providing comprehensive training and technical support. We understand that any new equipment can present challenges, and we aim to ensure that your team is fully prepared to maximize the efficiency and safety of your new machine from day one.

On-Site Training for Your Team

We offer hands-on, on-site training sessions designed to familiarize your operators with the ins and outs of the mold flipper. Our experienced engineers will guide your team through machine operation, troubleshooting, safety protocols, and routine maintenance procedures. This training is designed to ensure your staff feels confident in using the equipment efficiently, thus avoiding costly mistakes or accidents.

Remote Training Options and Video Tutorials

In addition to on-site training, we provide remote learning options such as video tutorials and live webinars. This ensures that your team has access to training materials at any time, whether they need a refresher course or have new team members who require onboarding. These resources help keep your workforce up-to-date with the latest operational procedures and technical support solutions.

What You Get with Our Training and Support:

Hands-On Training: On-site training sessions where our experts teach your team everything they need to know about operating and maintaining the mold flipper.

User-Friendly Documentation: Comprehensive manuals and user guides that explain machine operation, maintenance schedules, and safety features.

Remote Support: Access to online support through video tutorials, webinars, and live consultations for any technical assistance needed.

Why Training and Technical Support Matter

Proper training is the key to making the most out of your new mold flipper. It reduces the likelihood of operational errors and enhances the safety of your team. By providing continuous support, we make sure that your production process runs smoothly without unnecessary delays or confusion.

7. How do we design our Mold flipper to grow alongside your business and stay ahead of industry trends?

At FHOPEPACK, we understand that your business is constantly evolving. To ensure that your investment continues to deliver value in the long term, we design our mold flippers with scalability and future-proofing in mind. Our goal is to create equipment that not only meets your current needs but can also adapt to changing production demands and industry advancements.

Modular Design for Flexibility

Our mold flippers are built with a modular design that allows for easy upgrades and modifications as your business grows. Whether you need additional capacity, new features, or compatibility with other machinery, we offer customizable options to keep pace with your expanding operations.

Staying Ahead of Industry Trends

In an ever-changing market, staying ahead of industry trends is crucial. FHOPEPACK continuously monitors advancements in automation, materials handling, and industry standards. We incorporate these trends into our mold flipper designs, ensuring that our equipment is always at the forefront of technology. This commitment to innovation means that your mold flipper will be equipped with the latest features, improving your operational efficiency and reducing future upgrade costs.

How We Future-Proof Your Mold Flipper:

Scalable Design: Easily upgradeable components that allow you to add features or increase capacity as needed.

Cutting-Edge Technology: Integration of the latest automation and sensor technologies to keep your equipment competitive.

Adaptability: Designed to accommodate new industry standards, making it easier for your business to comply with evolving regulations.

Future-proofing is about making an investment that will continue to pay off as your needs evolve. With our mold flippers, you can trust that you’re getting equipment designed for long-term success.

8. How do we optimize our delivery and installation process to minimize disruptions and delays?

Timely delivery and hassle-free installation are essential for keeping your production schedule on track. At FHOPEPACK, we take pride in our efficient delivery and installation processes. By focusing on streamlined logistics and smart planning, we ensure that the mold flipper is up and running in the shortest time possible, without disrupting your ongoing operations.

Fast and Reliable Delivery

We understand the importance of meeting deadlines. That’s why we keep a stock of mold flippers ready for shipment, ensuring quick turnaround times. Depending on your location, our delivery typically takes just 3-5 business days. You won’t have to wait weeks for your new machine to arrive—your production can continue to operate smoothly while waiting for the mold flipper to be delivered.

Minimal Installation Requirements

Our design team has also made installation as straightforward as possible. Unlike other equipment that may require complicated setups, our mold flippers are designed with minimal installation requirements. All that’s needed is basic de-packing, followed by connecting the power and air supply. To make the process even easier, we provide a video guide and a detailed manual to walk your team through the setup.

Key Aspects of Our Delivery and Installation Process:

Machines in Stock: We keep a ready inventory of mold flippers for fast delivery.

3-5 Days Delivery: Quick shipping to minimize waiting time.

Simple Installation: Minimal on-site work—just de-packing, power, and air connection.

Support Materials: Video guides and manuals to assist with setup.

Why Our Delivery and Installation Process Matters

Time is money, and a delayed installation can set back your production schedule. With FHOPEPACK, you can count on a fast and smooth transition to your new equipment. Our commitment to quick delivery and easy installation ensures that your business experiences minimal disruption and maximum uptime.

9. How do our real-world case studies highlight the effectiveness of our solutions?

At FHOPEPACK, we don’t just claim our equipment is effective—we demonstrate it through real-world case studies. These stories from businesses that have integrated our mold flippers into their operations serve as a testament to the reliability, efficiency, and value of our solutions. By showcasing tangible results from our customers, we provide you with a clearer picture of how our equipment can make a real difference to your business.

Demonstrating Real Results

Our case studies cover a wide range of industries, from automotive to construction, where the mold flipper has significantly improved production processes. These success stories highlight key areas such as time savings, safety improvements, and the reduction of damage during handling. We present data-driven results showing how our equipment enhances productivity and efficiency, helping businesses achieve a higher return on investment.

Key Benefits Highlighted in Our Case Studies:

Increased Efficiency: Clients have reported a 25-40% reduction in handling time after adopting our mold flippers.

Enhanced Safety: Safety improvements in production lines have been noted, with a significant decrease in workplace injuries related to mold handling.

Reduced Downtime: Several companies have experienced less operational downtime thanks to the reliability and ease of maintenance of our mold flippers.

Real-World Examples of Success:

Automotive Industry: A leading automotive supplier reduced mold handling time by 30%, increasing overall production throughput.

Construction Sector: A major construction material supplier reported a 50% reduction in equipment damage during mold transfers, thanks to the precision of our mold flipper.

These case studies aren’t just testimonials—they are a reflection of our commitment to delivering machinery that has a proven impact on your operations.

10. How do we design our contract terms to be both transparent and protective of your investment?

At FHOPEPACK, we believe in offering not only excellent products but also fair and transparent contract terms that protect your investment. We understand that purchasing industrial equipment is a significant decision, and it’s vital that our clients feel confident in the value they’re receiving. Our contract terms are designed to provide clarity, flexibility, and protection from unexpected costs.

Clear and Transparent Pricing

When you purchase a mold flipper from us, there are no hidden fees or surprise costs. Our pricing structure is straightforward, and we ensure that all associated costs—including shipping, installation, and training—are clearly outlined from the outset. We take pride in offering value that aligns with your budget while ensuring you receive top-quality machinery and service.

Flexible Terms for Peace of Mind

Our contracts are designed with your business’s needs in mind. We offer flexible payment terms to accommodate your budget, whether it’s through upfront payments or installment options. We also include clear warranties and service agreements, so you know that your investment is protected long after the purchase.

Why Our Contract Terms Matter:

Transparency: No hidden costs, no surprises. You’ll always know exactly what you’re paying for.

Flexibility: Payment terms that fit your financial situation, making the purchase process easier to manage.

Protection: Strong warranties and service contracts that ensure your mold flipper remains an asset for years to come.

Our commitment to transparency and flexibility ensures that your investment in our mold flipper is secure and well-supported from the moment you sign the contract.

11. What makes our mold flipper a cost-effective solution?

In today’s competitive business environment, cost-efficiency is a top priority. With our mold flippers, we help you maximize your return on investment by significantly reducing costs related to labor, downtime, and equipment wear and tear. The combination of robust design, reliable performance, and long-term savings makes our mold flipper a cost-effective solution for any production line.

Reducing Labor Costs

One of the most notable advantages of using our mold flipper is the reduction in manual labor. Handling molds manually is a time-consuming and physically demanding process that often results in safety concerns and errors. With our mold flipper, the process is automated, reducing the need for manual labor, cutting down on operational costs, and improving overall efficiency.

Labor Savings: Our clients report an average of 20-30% reduction in labor costs.

Improved Safety: Automation eliminates the need for heavy manual lifting, minimizing the risk of workplace injuries.

Decreasing Downtime

Downtime is a major expense for any manufacturing operation. With our mold flipper, businesses can enjoy faster setup times and more efficient mold changes, resulting in less downtime and greater productivity. The quicker you can switch molds, the more time your equipment spends in production, directly impacting your bottom line.

Increased Production Time: Many of our customers report up to 40% more productive hours each day due to reduced downtime.

Lower Maintenance Costs: Our mold flippers are built for durability and require less maintenance, further lowering your operational costs.

Case Studies and Cost Analysis:

Automotive Industry: A client in the automotive sector reported a 35% increase in mold change efficiency, leading to a reduction in production costs by 25%.

Construction Industry: In the construction materials sector, our mold flippers helped a customer cut labor expenses by 15%, as fewer workers were needed for mold handling.

These figures demonstrate just how cost-effective investing in a mold flipper can be for your business.

12. How do we support you with ongoing maintenance and upgrades?

We understand that keeping your equipment in optimal condition is crucial for continuous productivity. Our after-sales support is designed to ensure your mold flipper remains in peak working condition for years to come, with minimal downtime and maximum efficiency.

Preventative Maintenance and Support

To keep your equipment running smoothly, we offer comprehensive preventative maintenance packages. These packages are tailored to your production schedule and needs, ensuring that your mold flipper undergoes regular checks and servicing to avoid any unexpected breakdowns.

Scheduled Maintenance: We offer annual or semi-annual maintenance services to keep your mold flipper in perfect working condition.

Quick Response: Should you encounter any issues, our service team is always ready to respond with fast and efficient troubleshooting, either remotely or through on-site visits.

Software Updates and Upgrades

We don’t just focus on hardware—our mold flippers come with the option for software upgrades, ensuring that you always have access to the latest technology and features. These upgrades can help improve functionality, enhance safety features, and increase overall efficiency.

Ongoing Support Features:

24/7 Online Support: Our customer service team is available to answer any questions or provide troubleshooting advice.

On-Site Visits: For more complex issues, we provide on-site visits to quickly resolve any problems.

Flexible Upgrade Options: As technology evolves, we provide software upgrades to keep your equipment in line with the latest industry standards.

With ongoing support, we ensure that your investment continues to deliver value and performs at its best throughout its entire lifespan.

Conclusion

At FHOPEPACK, our mold flippers are more than just machines—they are strategic investments that can transform your production process. From reduced labor costs to improved efficiency and safety, our solutions are designed to offer maximum value with a clear return on investment.

With over 15 years of experience, a reputation built on trust, and a comprehensive support system, we are here to help you find the best mold flipper solution tailored to your specific needs. Whether you’re looking to optimize production, reduce costs, or ensure long-term operational efficiency, FHOPEPACK is your partner for success.

Feel free to reach out to us for more details on how our mold flippers can improve your operations. We look forward to supporting your business growth with reliable and cost-effective solutions.