Mold Flipper for 5T

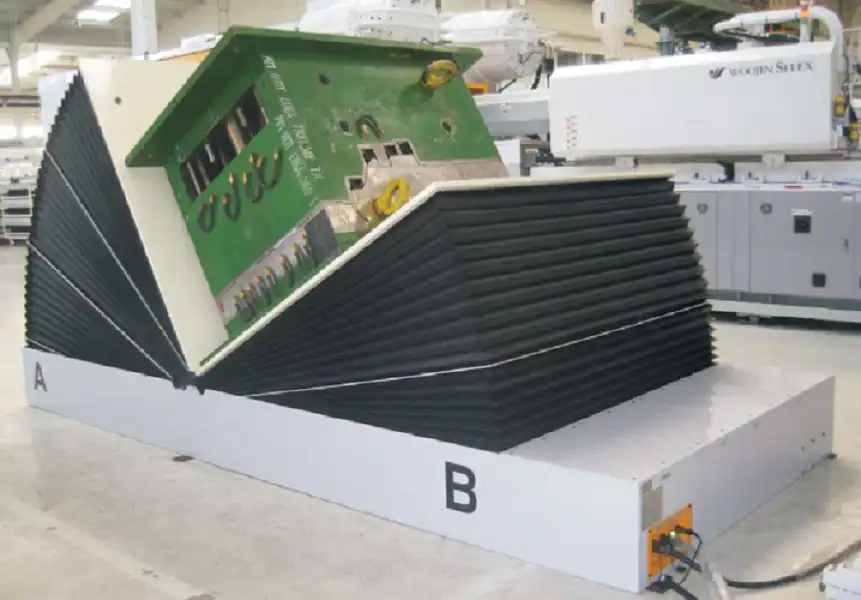

The Mold Flipper Table is a reliable and efficient solution for handling molds up to 5 tons. Designed for medium to large mold operations, it simplifies maintenance and repairs while ensuring safety and precision. With advanced hydraulic controls and robust safety features, this table is ideal for industries requiring accurate and secure mold manipulation.

Model Type: FPMT-05

Load Capacity: 5 Tons (5000 Kg)

Table Dimensions: 3100 × 1400 × 450 mm

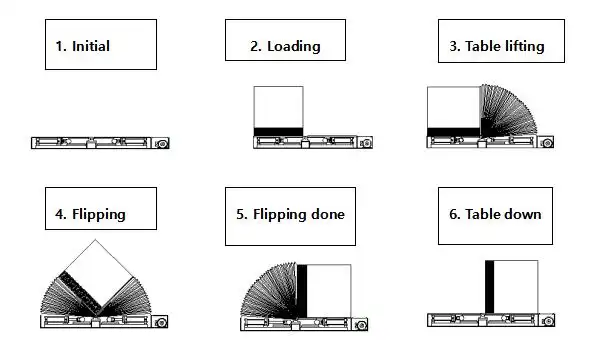

Rotation Angle: 180 Degrees (Full Flipping)

Operational Speed: 15–30 Seconds per Flip

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

A mold flipper for 5T is a robust and efficient machine designed to handle heavy molds weighing up to 5 tons. It streamlines mold flipping tasks with precision, ensuring safety and reducing manual labor. Ideal for industrial applications, it enhances productivity while minimizing risks during mold handling operations.

Mold Flipper Table for 5T Mold and Die

The Mold Flipper Table is a specialized solution designed for handling and inverting molds weighing up to 5 tons. This table is an essential addition to operations involving medium to large molds, particularly when paired with vertical die spotting presses. By enabling efficient and safe flipping of molds, it simplifies maintenance, repair, and inspection processes. Industries requiring precise and reliable mold manipulation will benefit from its robust design and advanced features, ensuring seamless workflow and enhanced safety.

Key Benefits:

Efficient Handling: Reduces the time and effort required for mold flipping.

Enhanced Safety: Equipped with multiple safety features to protect operators and equipment.

Durability: Engineered for heavy-duty use with high-quality materials and components.

Customizable Speed: Adjustable operational speed to suit specific requirements.

Technical Specifications

| Specification | Details |

|---|---|

| Model Type | FPMT-05 |

| Table Dimensions | Length: 3100 mm, Width: 1400 mm, Height: 450 mm |

| Maximum Load Capacity | 5 tons (5000 kg) |

| Motor Power | 5.2 kW |

| Total Machine Weight | 5 tons (5000 kg) |

| Hydraulic Oil Capacity | 12 liters |

| Maximum Rotation Angle | 180 degrees (complete flipping capability) |

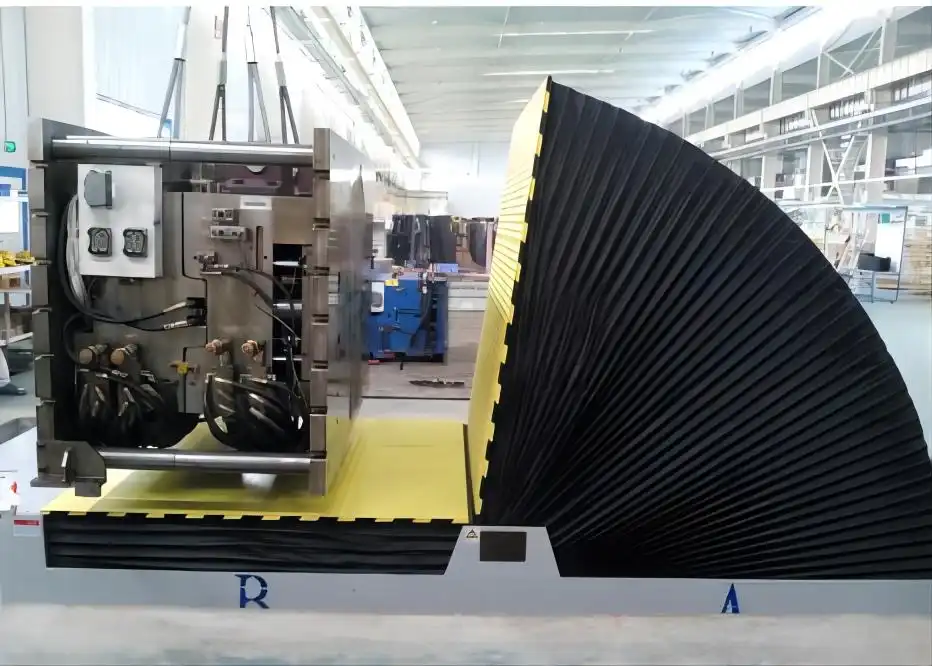

| Control System | Advanced hydraulic system with remote control |

| Safety Features | - Emergency stop - Overload protection - Safety fence - Interlock and safety guards |

| Operational Speed | Adjustable, completing a full flip in 15–30 seconds |

Additional Features:

Advanced Hydraulic System: Ensures smooth and consistent flipping with minimal noise.

Remote Control Functionality: Enables operators to manage flipping operations from a safe distance, enhancing convenience and safety.

Overload Protection: Prevents damage by stopping operations when the load exceeds the rated capacity.

Emergency Stop: Quickly halts operations during emergencies to minimize risks.

Customizable Speeds: Adjust the flipping speed to match operational demands for maximum efficiency.

Applications:

The Mold Flipper Table is ideal for industries such as:

Plastic injection molding

Die casting

Automotive component manufacturing

Aerospace and heavy machinery industries

Why Choose the Mold Flipper Table?

This Mold Flipper Table is engineered to provide unparalleled reliability and precision for 5-ton mold and die handling tasks. It not only streamlines mold maintenance processes but also ensures a safer and more efficient workspace. Its advanced safety mechanisms and operational flexibility make it a trusted asset for businesses aiming to optimize their mold management workflows.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635