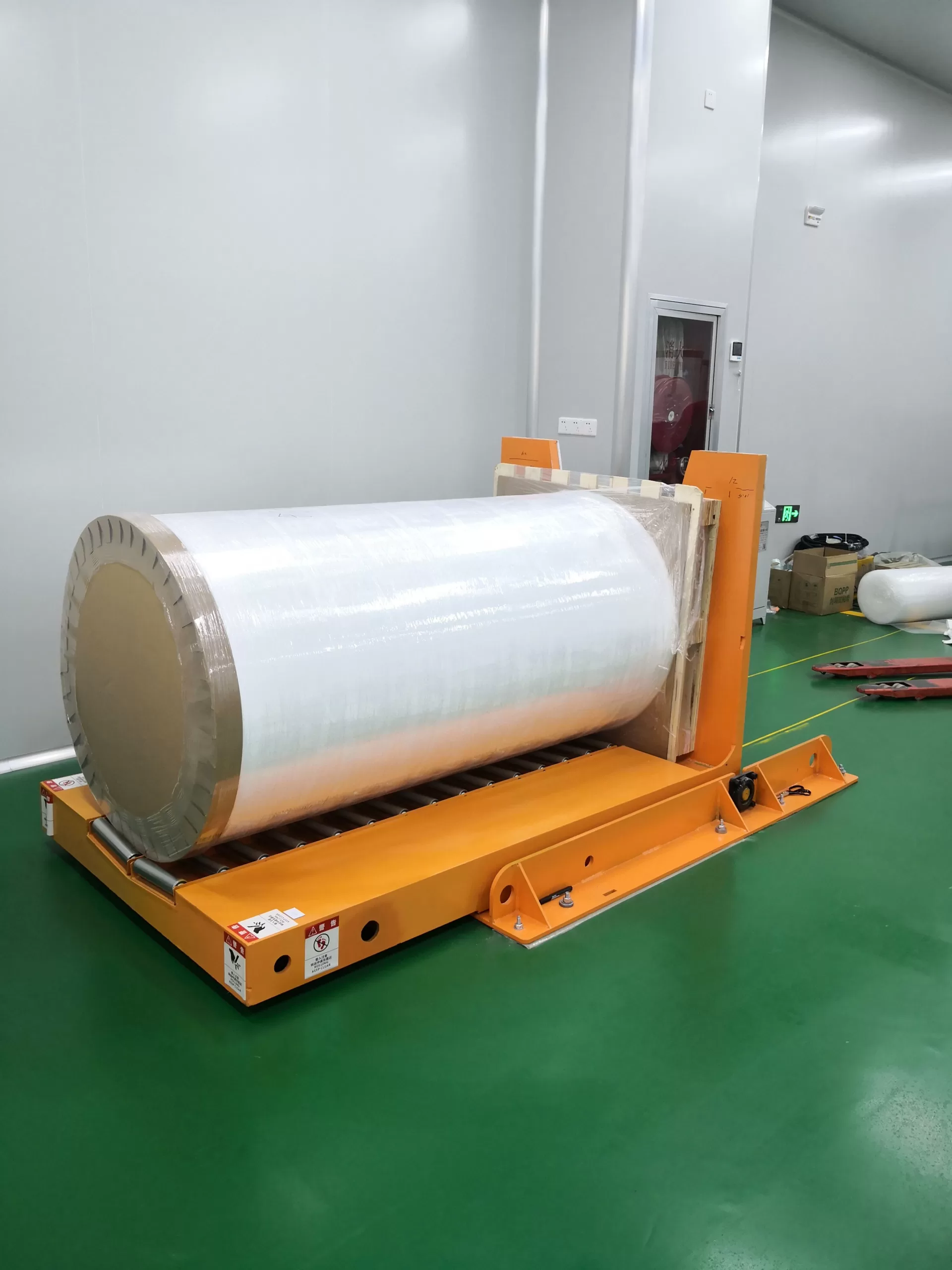

Hydraulic upender

A hydraulic upender is an industrial machine designed to safely and efficiently tilt or rotate heavy loads, such as steel coils, molds, or other bulky items. Using hydraulic power, it ensures precise handling, reduces labor strain, and enhances workplace safety. Its robust construction and customizable features make it ideal for manufacturing, warehousing, and heavy-duty operations.

Fhope hydraulic upender manufacturer, the hydraulic upending machine is designed with stability for tilting products, which can dramatically enhance the working efficiency

Our hydraulic upenders can handle heavy work smoothly and effectively.

They use one or more double acting cylinders to rotate the platform. A platform can be significantly smaller than others. The ideal load of these upenders is not symmetrical, such as long and cylindrical. The hydraulic upenders can handle heavy work smoothly and effectively.

They use one or more double acting cylinders to rotate the platform. A platform can be significantly smaller than others. The ideal load of these upenders is not symmetrical, such as long and cylindrical.

Ask For a Quick Quote

The first 3 people who consult today will receive a free consumable parts package.

Hydraulic upender

Hydraulic upender

A floor base hydraulic upender/tilter is a machine that is used to rotate heavy objects during operations. It has a stable and solid structure that can handle heavy loads, and is designed for easy operation and operator safety. Additionally, it requires minimal maintenance.

Hydraulic tilter

A hydraulic tilter is an industrial machine that utilizes hydraulic systems to tilt heavy materials like coils, molds, or containers. It ensures smooth operation, enhances workplace safety, and minimizes manual effort. Suitable for various industries, it improves efficiency and handles heavy loads with precision and reliability.

Roll upender

Roll upender is a machine used for handling large rolls of paper, curtain, and carpet, it has a heavy-duty and durable structure and is designed for safe operation. The manufacturer, Fhope, aims to provide a safe operating environment for the operator.

Upender

The Hydrauliccoil upender machine is a custom-designed flat tilter that can handle a load of up to 40Tmold. The upending process involves raising one half of the upender to 90 degrees, loading the tool against the raised half, and then simultaneously rotating both halves to rotate or upend the tool by 90 degrees for servicing.

Mold flipper

The Flipper Lift Table is a machine designed for flipping molding boxes (for mating response to drag or for sand shake off) with a safe and efficient operation. It can handle any size portion from 100 LBS to over 100 tons, simply by pressing a button. This makes it very versatile and useful in many industrial applications.

Mold flipper table

The Inject Mold flipper table is a specialized equipment designed for 180 degree turning and flipping of molds, dies, and other heavy tools in a safe and efficient operation. It is an essential piece of equipment in the production of molds. The equipment is designed to handle the heavy tools securely and allowing the 180 degree rotation and flipping of the molds, dies and other tools safely.

Packaging Cases

We have exported to more than 50 countries. Powerful service internet and install team makes us build relationships with customers who come from European, Middle East, South America, South East Asia.

Get The Best Solutions for Your Building!

Why Choose Us

Superior design, uncompromising quality and a growing list of satisfied customers have made Fhope a pioneer in the industry. All main core parts with EN81-20 and 50 certificate

15+ years experience

With 15+ years experience in the packaging machinery industry, with deep understanding of the specific needs of various industries, including steel, automotive, and construction materials.

Professional Technical Team

10 mechanical engineer, 8 electrical engineer, 4 service engineer, with 15 high skill technician ensure the precise and innovative solutions.

OEM And ODM Design

With Excellent Technology and Advanced design, to make the machine in semiauto or automated matches to your packaging goal 100%

24/7 after services

We offer top-notch after-sales services including on-site installation, training, and maintenance support. Our dedicated team ensures minimal downtime and fast issue resolution to keep your production line efficient.

Top Cost performance

Engineered for Efficiency and Longevity. Benefit from our high cost performance machine with comprehensive support, including expert installation, thorough training, and responsive maintenance.

Global Standard

With installations in multiple countries, we have a global presence but also understand the specific requirements and regulations of regional markets. This allows us to offer localized support while maintaining high global standards.

Frequently Asked Questions

Here are the most common questions about packing machines. If you can’t find what you need, call us on +8613951501635 or get in touch at info@fhopepack.com.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635