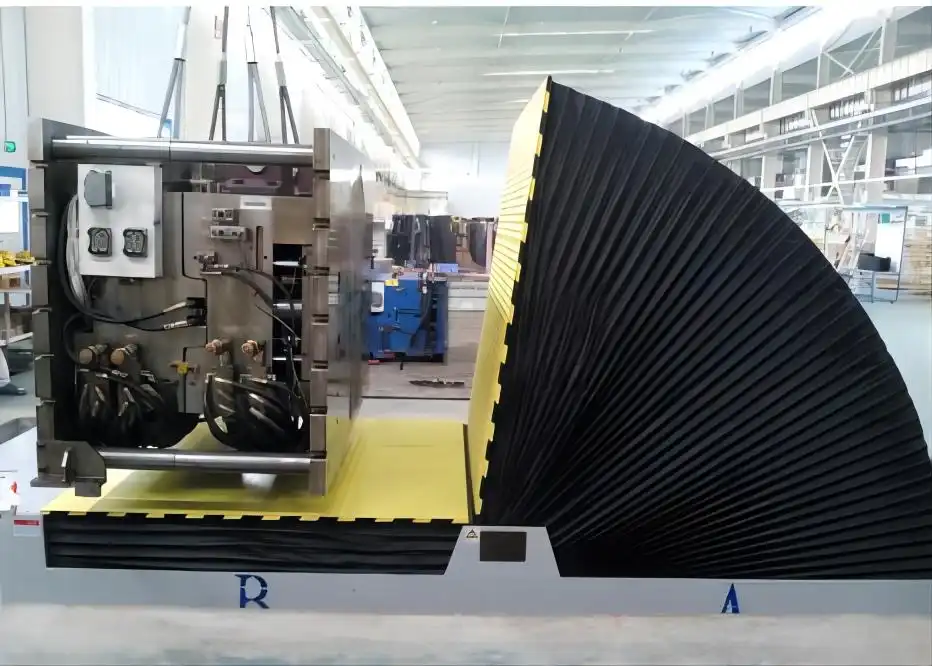

Mold flipper table

Manual mold handling with cranes is risky and prone to accidents. Mold flippers ensure safe, efficient 90- or 180-degree flipping, keeping operators away from danger.

Key Features

Safety: Equipped with limit switches, emergency stops, and hydraulic power for smooth, controlled operation.

Efficiency: Reduces manual handling risks and improves process speed.

Compact Design: Space-saving and adaptable for various layouts.

Quality: Fhopepack offers certified, heavy-duty solutions for molds from 10 to 100+ tons.

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

The Inject Mold flipper table is a specialized equipment designed for 180 degree turning and flipping of molds, dies, and other heavy tools in a safe and efficient operation. It is an essential piece of equipment in the production of molds. The equipment is designed to handle the heavy tools securely and allowing the 180 degree rotation and flipping of the molds, dies and other tools safely.

Mold flipper table

180°Mold Flipper

Enhancing Safety and Efficiency with Mold and Die Flippers

Handling molds and dies manually with cranes poses significant risks, as even minor errors can lead to accidents. Operators are often required to stand beneath the hook and move alongside the mold, exposing them to potential harm. Mold flippers provide a safer and more efficient alternative, ensuring smooth and controlled handling processes.

Benefits of Mold Flippers in Industrial Operations

Improved Safety Standards

The mold flipper ensures that operators remain at a safe distance from the hook and mold.

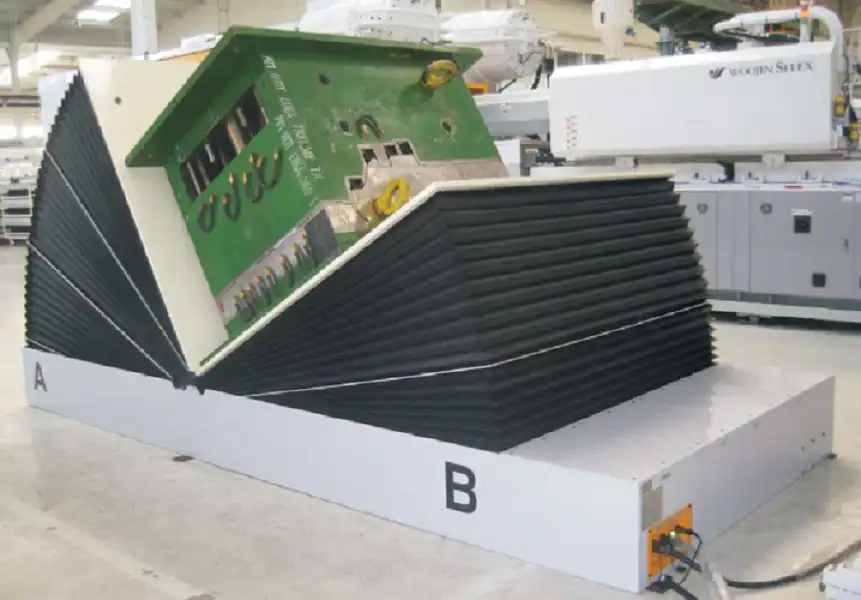

It minimizes risks associated with manual handling by offering controlled flipping mechanisms for 90 and 180-degree turns.

Operators benefit from reduced exposure to hazards, creating a safer working environment.

Enhanced Efficiency

Mold flippers eliminate the need for manual intervention, streamlining the mold production process.

The machine's precise handling improves productivity, reducing downtime caused by accidents or inefficiencies.

Key Features of Mold Flippers

Advanced Security Mechanisms

Equipped with electric limited switches and mechanical stoppers for emergency situations.

The machine can halt operation at any angle during a power outage.

An adjustable inverter controls tilting speed, ensuring smooth starts and stops.

Hydraulic power ensures impact-free handling, providing stable and secure operation.

Compact and Flexible Design

Mold flippers are space-efficient, suitable for tight facility layouts.

Can be installed on the floor or in a pit for ground-level operations.

Maintenance-friendly design ensures easy access to the working table and hydraulic station.

Fhopepack: A Leader in Mold and Die Handling Solutions

Fhopepack specializes in the design and production of heavy-duty material processing equipment for molds and dies. Their solutions cater to capacities ranging from 10 tons to over 100 tons, ensuring flexibility for diverse industrial needs.

Certifications and Standards:

Fhopepack meets stringent 3C and CE certification standards, guaranteeing high-quality and safe products.

Industry Experience:

With over 15 years of expertise, Shanghai Fhope Machinery Co., Ltd has delivered cutting-edge solutions, including injection molding upenders up to 4,400 tons.

Product Innovation:

Their rapid mold replacement systems exemplify the company's commitment to improving industrial safety and efficiency.

Why Choose Mold Flippers for Your Facility?

Investing in a mold flipper not only enhances operational safety but also boosts productivity. By automating the mold-flipping process, companies can reduce risks, improve turnaround times, and optimize space utilization. For industries requiring heavy-duty solutions, Fhopepack stands out as a trusted provider, delivering robust and reliable equipment tailored to meet the demands of modern manufacturing.

Technical Specifications

| Parameter | Details |

|---|---|

| Operational Mechanism | Hydraulic drive system for smooth and efficient flipping |

| Power Source | Electric-hydraulic power system |

| Safety Features | Safety interlocks and emergency stop functionalities |

| Flipping Speed | High-speed flipping to minimize downtime |

| Model Type | FPMT-40 |

| Table Dimensions | Length: 4500 mm, Width: 2400 mm, Height: 500 mm |

| Maximum Load Capacity | 40 tons (40,000 kg) |

| Motor Power | 7.5 kW |

| Machine Weight | 40 tons (40,000 kg) |

| Hydraulic Oil Capacity | 15 liters |

| Maximum Rotation Angle | 180 degrees (full flipping capability) |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635