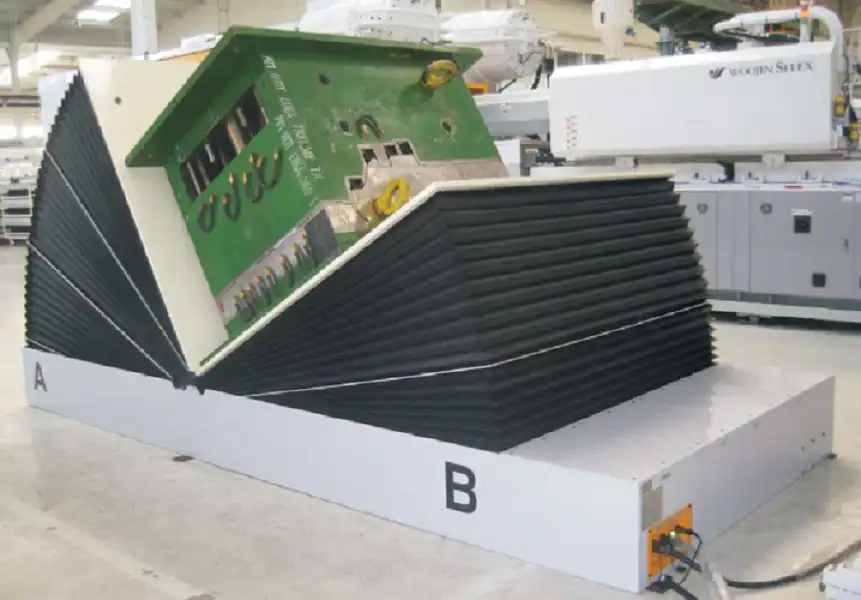

180 Degree Mold Upender 5T

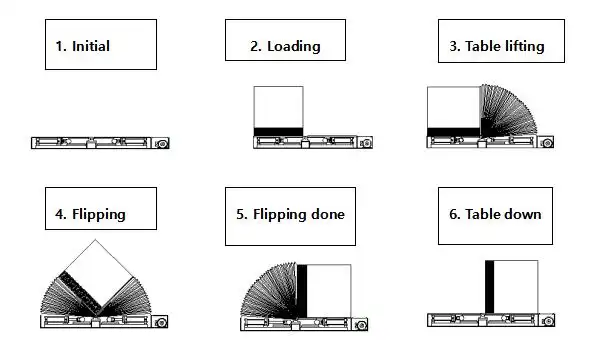

The 180-Degree Mold Upender 5T simplifies and secures the flipping of molds up to 5 tons, enhancing safety and efficiency in manufacturing environments. With its robust steel construction, dual control modes, and low maintenance requirements, it is a reliable solution for industries like injection molding, die casting, and heavy manufacturing.

Parameters

Coil Weight Capacity: Up to 6,000 kg

Line Speed: 160-320 coils per 8-hour shift

Automation Level: Semi-automatic or Fully Automatic

Material Compatibility: Carbon Steel, Stainless Steel, Aluminum

Packaging Options: Stretch Film, VCI Paper, Steel Straps

Safety Features: Overload Protection, Emergency Stops, Advanced Sensors

Special Features

Smooth and Safe Rotation

Enables effortless tilting and upending of heavy loads, reducing handling risks and improving workplace safety.

Heavy-Duty Load Capacity

Designed to handle large and bulky items, making it ideal for demanding industrial applications.

Compact and Space-Saving Design

Occupies minimal floor space while delivering maximum functionality, optimizing workflow efficiency.

Related video

The 180 Degree Mold Upender 5T is a robust and efficient solution designed to safely and seamlessly rotate heavy molds up to 5 tons. With precise handling, durable construction, and enhanced safety features, it optimizes workflow in industrial settings, reducing manual labor and improving operational efficiency. Ideal for heavy-duty mold management tasks.

Die Flipper | 180-Degree Mold Upender 5T

The 180-Degree Mold Upender 5T revolutionizes mold handling by enabling the safe, efficient, and precise flipping of molds weighing up to 5 tons. Engineered for demanding industrial applications, this equipment enhances workflow efficiency while maintaining high safety standards, making it indispensable for modern manufacturing environments.

Key Features

Safe and Precise Rotation: Provides accurate flipping with full 180-degree rotation, reducing the risk of mishandling.

Heavy-Duty Construction: Manufactured with a robust steel frame, ensuring long-term durability and reliable performance.

Dual Control Modes: Allows for both manual and semi-automatic operation, catering to diverse operational needs.

Low Maintenance: Designed for ease of upkeep, requiring only annual check-ups for optimal performance.

Technical Specifications

| Specification | Details |

|---|---|

| Power Source | Electrically operated with optional hydraulic enhancements |

| Control System | Dual mode (manual and semi-automatic) |

| Material Construction | Heavy-duty steel frame |

| Model Type | FPMT-5 |

| Table Dimensions | Length: 2500 mm, Width: 2000 mm, Height: 450 mm |

| Maximum Load Capacity | 5 tons (5,000 kg) |

| Motor Power | 7.5 kW |

| Machine Weight | 5 tons (5,000 kg) |

| Hydraulic Oil Capacity | 15 liters |

| Maximum Rotation Angle | 180 degrees |

Applications

The 180-Degree Mold Upender 5T is perfectly suited for industries that require frequent, safe, and efficient mold flipping operations. Key application areas include:

Injection Molding: For precise and safe handling of molds used in plastic part production.

Die Casting: Ensures secure flipping of heavy molds used in metal casting processes.

Heavy Manufacturing: Supports various manufacturing processes requiring robust mold handling.

This equipment stands as a cornerstone of efficient mold handling in high-demand environments, ensuring operational safety, productivity, and longevity. Its versatility and durability make it a valuable investment for any industry requiring heavy-duty mold management.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635