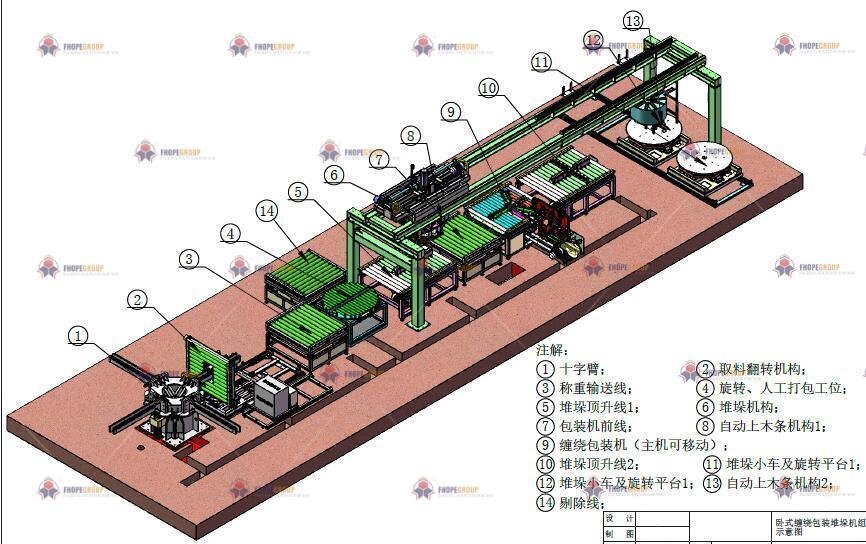

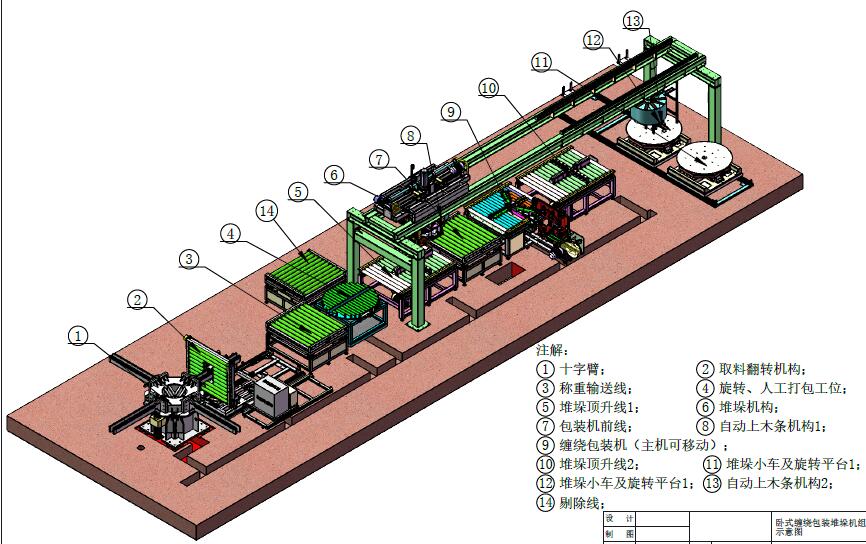

Automatic steel coil wrapping line

Designed for use in a rolling-extrusion shop to automatically package strip coils after cutting on a slitting-and-shearing line. It handles the entire process, from coil turning to stacking.

Key Components

Turnstile

Heavy-duty loading system with a robust structure.

Equipped with 2 or 4 arms, adjustable to the slitting line speed requirements.

Handles loads up to 60 tons, with arm extensions up to 2000 mm to fit different coil types.

Down Ender

Automatically separates and picks up coils from the turnstile.

Features a hydraulic lifting nose, adjustable for different coil widths.

Includes a roller conveyor table and a coil falling protection mechanism.

Wrapping Machine

Used for applying protective wrapping tape to coils.

Adjustable features include wrapping tape tension, ring speed, and roller speed, controlled via inverters.

Stacking Machine

Gantry-type mobile system with a mechanical coil lifter.

Smoothly and quickly picks up and moves coils.

Special Features

Enhanced Production Efficiency

Significantly boosts packaging speed and reduces human errors, making it ideal for large-scale production.

Reduced Operational Costs

Lowers labor costs and minimizes material waste, offering substantial long-term cost savings.

Consistency and High Quality

Ensures standardized and high-quality packaging, enhancing customer trust and satisfaction.

Related video

The automatic steel coil wrapping line is a high-efficiency system tailored for seamless, automated steel coil packaging. It optimizes wrapping precision, reducing labor needs and packaging time. Perfect for heavy industry applications, it provides robust protection for coils during transport and storage, ensuring product integrity.

The new coil packing line equipment is designed for use in a rolling-extrusion shop, where it can be used to automatically package strip coils after they have been cut on a slitting-and-shearing line. The system is designed to handle the entire packaging process, from coil turning to stacking, and it includes several key components.

One of these components is a turnstile, which is a heavy-duty loading system with a strong structure. The turnstile can be equipped with 2 or 4 arms, depending on the speed requirements of the slitting line, and it can handle loads of up to 60 tons. The arms of the turnstile can be extended up to a length of 2000 mm to accommodate different types of coils.

The system also includes a down ender, which is used to automatically separate and pick up coils from the turnstile. The down ender is equipped with a hydraulic lifting nose that can be adjusted for different coil widths, and it has a roller conveyor working table to support the coils. The down ender also has a coil falling protection mechanism to prevent damage to the coils.

The system also includes a wrapping machine, which is an eye-through type machine with a conveyor working table. The wrapping machine can be used to apply protective wrapping tape to the coils, and it has several adjustable features that allow the user to control the wrapping process. These features include the wrapping tape tension, the ring speed, and the roller speed, which can all be adjusted using inverters.

Finally, the system includes a stacking machine, which is used to handle the packed coils and stack them on pallets. The stacking machine is a gantry-type mobile mechanism with a mechanical coil lifter that can pick up and move coils smoothly and quickly. It is designed to be highly efficient and reliable, allowing for efficient and safe handling of the packed coils.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635