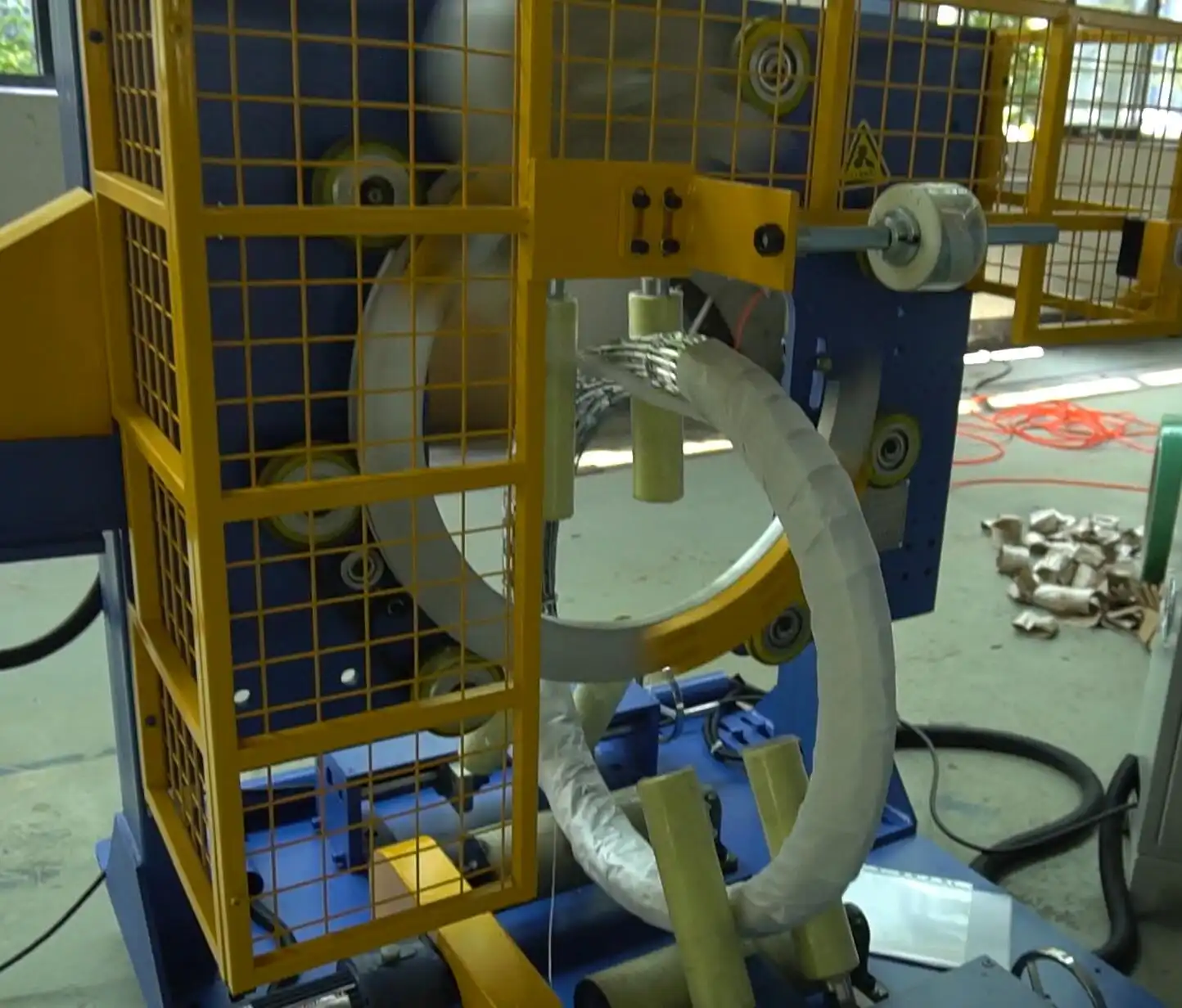

Razor wire wrapping machine

This innovative wrapping machine is designed to enhance efficiency, safety, and cost-effectiveness for coil packaging operations. Its modular construction and customizable design make it versatile and reliable for various applications, including specialized needs like razor wire coil packing.

Benefits:

Efficient Operations: Fast wrapping speeds, quick material changes, and short setup times streamline processes.

Adaptable and Customizable: Suitable for diverse applications with customizable designs for unique packaging needs.

Enhanced Safety: Prevents product damage and ensures operator safety, maintaining high-quality standards.

Cost Savings: Low energy and consumable requirements contribute to reduced operational costs.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

A razor wire wrapping machine is a specialized solution for securely bundling and packaging razor wire rolls. It provides protection from damage, ensures safe handling, and improves transport efficiency. Designed for reliability and precision, it enhances productivity and meets the stringent requirements of industrial and security industries.

Machine features:

- Modular constructed to easy maintaining: This feature makes it easier to maintain the machine as it is constructed using modular parts that can be easily replaced or serviced if necessary.

- High efficiency for coil packing: This feature ensures that the machine can wrap coils quickly and efficiently, reducing downtime and increasing productivity.

- Wide range of applicability, special size product will make a special design: This feature allows the machine to be used for a wide range of coil sizes, and special designs can be created to accommodate unique or specialized products.

- No risk of product damage and safety for operator: This feature ensures that the machine operates safely and there is no risk of damage to the products being wrapped, which is important for maintaining product quality and safety for the operator.

- Extremely low cost of consumable and energy: This feature makes the machine cost-effective to operate as it uses low-cost consumables and energy, helping to reduce overall operating costs.

- Machine running with low noise: This feature makes the machine quieter to operate, reducing noise pollution and creating a better working environment.

- Short set-up times required: This feature allows for quick and easy setup, reducing downtime and increasing productivity.

- Adjustable packing speed by inverter: This feature provides greater control over the wrapping process by allowing the packing speed to be adjusted using an inverter.

- Machine is occupied with a quick change dispenser for the wrapping material: This feature makes it easier to change the wrapping material quickly and efficiently, reducing downtime and increasing productivity.

- Tension of stretch film is variable, it is important in order not damage the products: This feature allows for the tension of the stretch film to be adjusted, ensuring that the products are not damaged during the wrapping process.

- The machine was special made for razor wire coil packing that is able cover the stretch film inside layer. And wrapping the paper, woven outside layer for protecting the package: This feature shows that the machine was designed specifically for the needs of razor wire coil packing, with a unique wrapping process that includes both stretch film and paper/woven outside layer for added protection

Technical parameter FPW300-W:

| Parameter | Specification |

|---|---|

| Object Weight | 10-100kg |

| Package Width | 200-300mm |

| Outer Diameter (OD) | 700-950mm |

| Inner Diameter (ID) | 450-700mm (OD-ID < 300mm) |

| Roller Speed | 2-4m/min |

| Wrapping Speed | 20-35sec/pcs |

| Rotating Speed | 40-100r/min |

| Overlap Scope | 20%-90% |

| Power Output | Approximately 1.5kw |

| Power Voltage | 380v/50Hz, 3Phase 5 wires |

| Packing Material | Crepe paper / Knit belt / Compound paper / HDPE |

| Material Dimensions | ID: 55mm, OD: 300-450mm, Width: 70-90mm |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635