Coil packing | Coil Wrapping Solution

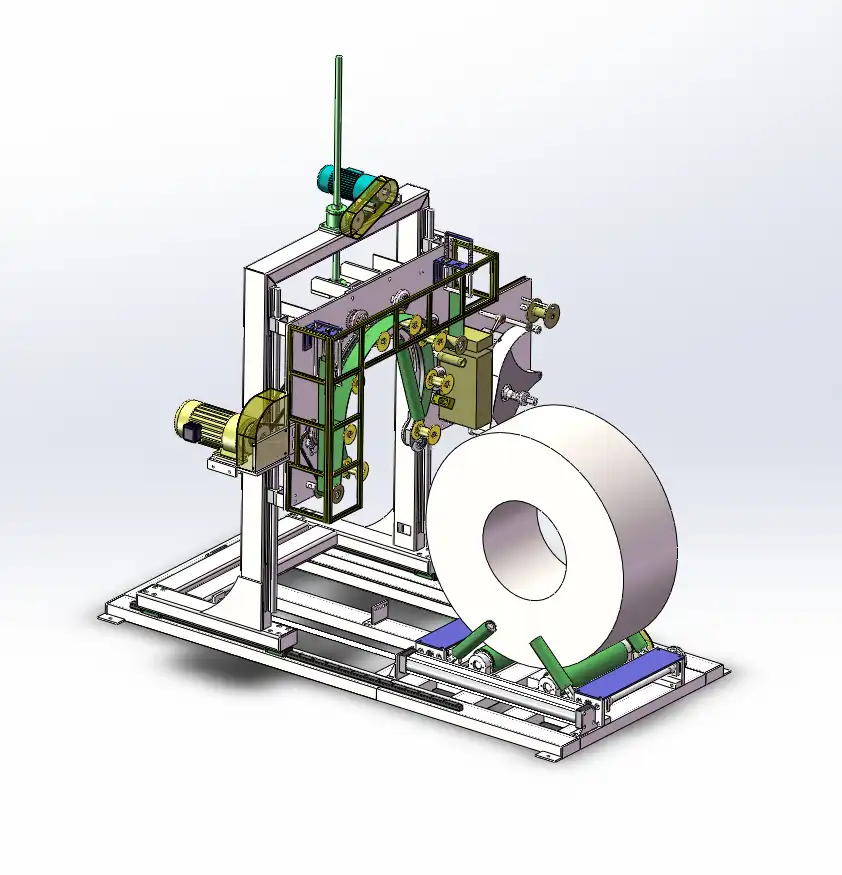

This highly efficient and versatile coil wrapping machine is designed to provide precise, safe, and cost-effective solutions for various coil packaging needs. Equipped with advanced features, it ensures consistent wrapping quality and easy operation for diverse applications.

Key Features:

Movable Wrapping Station:

Facilitates easy coil loading and unloading by returning to the initial position after each process.

Adjustable Packing Tape Overlap:

Controlled by an inverter for precise wrapping based on specific requirements.

Height-Adjustable Turning Ring:

Motor-driven adjustment accommodates different coil sizes.

Tension Control:

Adjustable packing tape tension ensures tight and secure wrapping.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

Coil packing and wrapping solutions are designed to securely package steel, wire, and aluminum coils for safe transport and storage. These systems offer enhanced protection against environmental factors, reduce damage risks, and streamline operations, ensuring efficient, cost-effective, and high-quality packaging for industrial and manufacturing needs.

Features:

- The wrapping station of the machine with movable function for easy loading and unloading: This feature allows for the wrapping station to be moved to the initial position for coil loading and then back to the initial position for coil unloading, making it easier to load and unload the coil.

- The overlap of packing tape can be adjusted by inverter: This feature allows for the overlap of packing tape to be adjusted using an inverter, giving greater control over the wrapping process.

- Level height of turning ring can be adjusted to suit different size of the coil packaging by motor: This feature allows for the height of the turning ring to be adjusted using a motor, making it possible to accommodate different sizes of coils.

- Packing tape tension can be adjusted: This feature allows for the tension of the packing tape to be adjusted, making it possible to achieve a tight and secure wrapping.

- Difference packing material can be choosing: This feature allows for different types of packing materials to be used depending on the requirements of the job.

- Supporting rollers are covered by polyurethane: This feature helps to protect the coils from damage during the wrapping process.

- Up and down supporting rollers are available: This feature allows for greater stability during the wrapping process, ensuring that the coil remains in place.

- Separate electrical box for safe operation and technical testing and trouble-shooting: This feature makes it easier to troubleshoot any issues that may arise during the operation of the machine.

- Separate material carriage and cutter device will make the packing process more efficiency: This feature makes the packing process more efficient by allowing for the separate carriage and cutter device to be used.

- Guardrails for loading and unloading safety: This feature helps to ensure the safety of the operators during the loading and unloading process.

- Soft stop and start: This feature allows for a gradual start and stop of the machine, reducing wear and tear on the components and making the operation smoother.

- Packing position reset: This feature allows for the packing position to be reset, ensuring consistency in the wrapping process.

- Ring speed adjustable by inverter: This feature allows for the speed of the turning ring to be adjusted using an inverter, providing greater control over the wrapping process.

- Rolls speed adjustable by inverter: This feature allows for the speed of the rolls to be adjusted using an inverter, providing greater control over the wrapping process.

- Friction between wheel and ring is adjustable: This feature allows for the friction between the wheel and the turning ring to be adjusted, providing greater control over the wrapping process.

- PU wheel which long life using: This feature ensures the durability of the machine by using polyurethane (PU) wheels which have a long lifespan.

- Packing material fix next to wrapping station: This feature allows for the packing material to be easily accessible and located near the wrapping station, making it easier to load the material onto the machine.

- Supportive rollers adjustment by motor: This feature allows for the supportive rollers to be adjusted using a motor, making it easier to accommodate different sizes of coils.

- Stretch film fix on the ring for the two layers(stretch film+paper) material wrapping at one time: This feature allows for the use of two layers of wrapping material (stretch film and paper) to be applied to the coil at one time, making the wrapping process more efficient.

- Wrapping station is movable: This feature allows for the wrapping station to be moved to the initial position for coil loading and then back to the initial position for coil unloading, making it easier to load and unload the coil.

| Parameter | Specification |

|---|---|

| Object Weight | 80-1000kg |

| Package Width | 100-500mm |

| Package Outer Diameter (OD) | 750-1500mm |

| Package Inner Diameter (ID) | 490-610mm |

| Wrapping Speed | 40-50 sec (OD:800mm, ID:508mm, Width:50mm) 50-65 sec (OD:1500mm, ID:508mm, Width:500mm) |

| Roller Speed | 2-4m/min |

| Rotating Speed | 10-90r/min |

| Overlap Scope | 10%-90% |

| Power Output | Approximately 3.0kw |

| Power Voltage | 380v/50Hz, 3Phase |

| Air Supply | 5-8 bar |

| Machine Size | Approximately L1600 x W1800 x H2000mm |

| Packing Material (Paper/HDPE/Knit Belt) | Width: 100-120mm, OD: 100-450mm, ID: 76mm, Thickness >85Gsm |

| Packing Material (Stretch Film/PVC Film) | Width: 100-120mm, OD: 100-200mm, ID: 76mm, Thickness >23 micron |

| Site Conditions | 5°C to 45°C, Humidity: 20%-99%, Dusty Atmosphere |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635