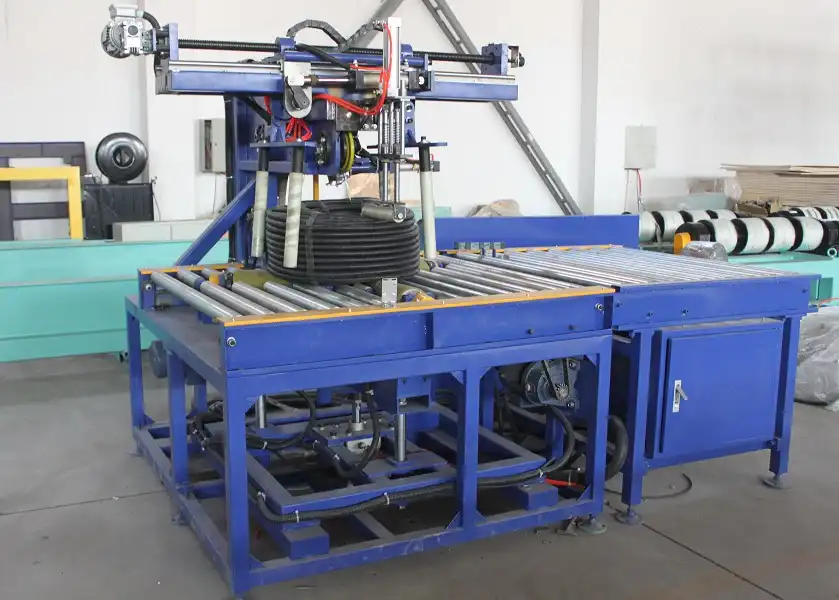

Automatic steel wire coil wrapping machine

The automatic steel wire coil packaging machine offers transformative advantages for the wire drawing industry, enhancing productivity, reducing costs, and ensuring product safety and quality. Below are its key benefits:

Key Technical Specifications and Features

Automation and Control

Equipped with a PLC & HMI system for automated and user-friendly operation.

Adjustable ring and roll speeds via inverters for tailored wrapping processes.

Material Compatibility and Protection

Supports a variety of packing materials for diverse applications.

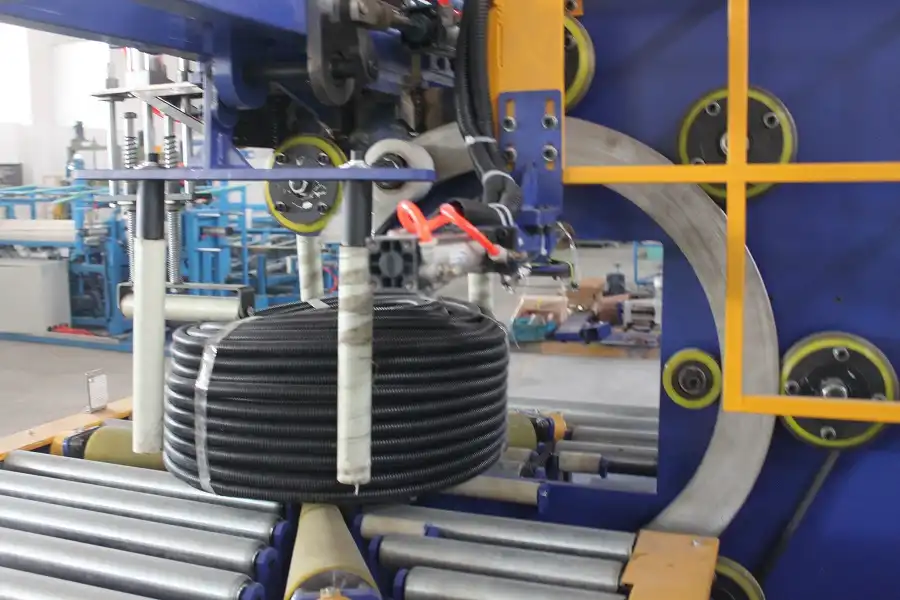

Polyurethane-Coated Rollers: Prevent scratches and damage to wire coils.

Protective Rollers: Four-sided rollers keep large coils stable during wrapping.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

An automatic steel wire coil wrapping machine provides a fast and reliable solution for securely wrapping steel wire coils. It uses protective materials to prevent damage, dust, and moisture during transport or storage. This machine enhances productivity, reduces labor costs, and ensures consistent, high-quality packaging for industrial needs.

The automatic steel wire coil packaging machine are significant for the wire drawing industry. The modular construction of the machine makes it easy to operate and maintain, and the mechanized wrapping is more efficient than manual packaging, which can save time and labor costs.

- The machine is equipped with a PLC & HMI program system for automatic wrapping, which ensures accurate and efficient operation.

- High-quality components from well-known brands are used, ensuring reliability and durability.

- The overlap of the packing tape can be adjusted by the inverter, providing flexibility for different wrapping requirements.

- The turning ring on the bottom of the machine makes operation easier and safer.

- The machine can accommodate different packing materials, allowing for customization to specific needs.

- The machine automatically adjusts its position according to the size of the wire coil's OD.

- The packing tape tension can be adjusted using a special brake device, ensuring that the product is wrapped tightly without damage.

- The supporting rollers are covered with polyurethane, which protects the wire coil from damage during the packaging process.

- Special side protective rollers are used for big size coils, ensuring stability and safety during packaging.

- Four sides protective rollers are used to keep the wire coil fixed and stable during the wrapping process.

- The distance between protective rollers can be adjusted according to the size of the coil being wrapped.

- A separate electrical box is included for safe operation, technical testing, and troubleshooting.

- Guardrails are used to ensure safety during operation.

- Soft start and stop features are included to prevent sudden jolts that can damage the product.

- The packing position can be reset, ensuring accuracy and consistency during the packaging process.

- The ring speed is adjustable using the inverter, allowing for customization to specific needs.

- The roll speed is adjustable using the inverter, ensuring accurate and efficient wrapping.

- The friction between the wheel and ring can be adjusted, ensuring that the wire coil is wrapped tightly without damage.

- The PU wheel used in the machine is designed for long life.

- A roller conveyor is included for in-feeding and out-feeding of wire coils, ensuring a smooth and efficient packaging process.

Basic data:

| Parameter | Specification |

|---|---|

| Object Weight | 300-1500kg |

| Package Width | 100-300mm |

| Package Outer Diameter (OD) | 500-1200mm |

| Package Inner Diameter (ID) | 300-900mm |

| OD-ID | <500mm |

| Roller Speed | 2-4m/min |

| Rotating Speed | 0-90r/min |

| Overlap Scope | 10%-90% |

| Power Output | Approximately 3.8kw |

| Power Voltage | 380v/50Hz, 3Phase |

| Packing Material | Stretch Film / Paper |

| Material Dimensions | ID: 50mm, OD: 150-250mm, Width: 120mm |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635