Wire coil wrapping machin FPW-600

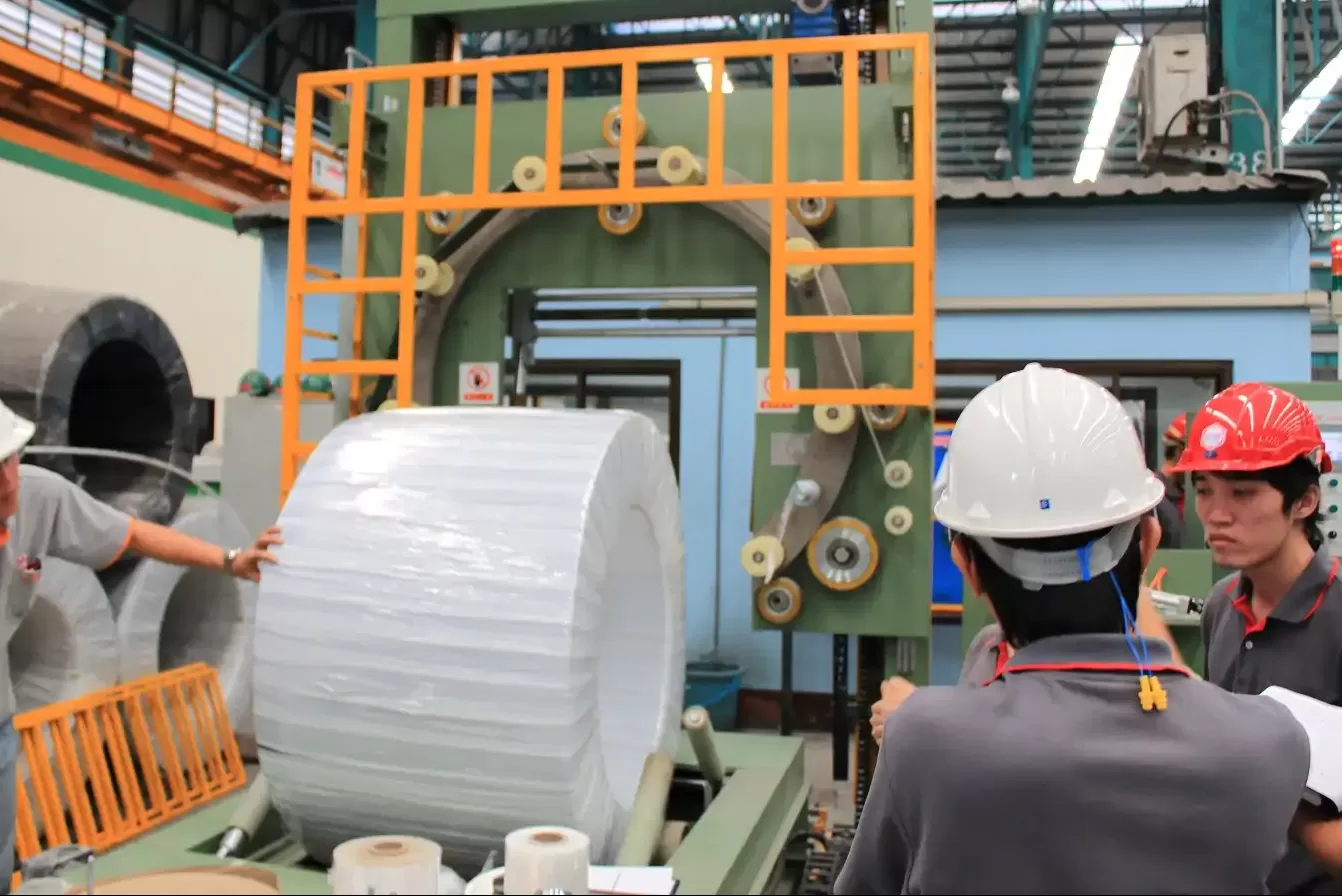

The FHOPE FPW-600 Wrapping Machine is designed for efficient and safe metal coil packaging, featuring a loading and unloading cart for streamlined material handling. With support for multi-layer wrapping and compatibility with various packaging materials, this machine reduces labor costs and material consumption while ensuring a stable and tidy wrapping process.

Key Features:

Flexible Operation: Offers both automatic and semi-automatic modes for adaptable packaging needs.

Durable Construction: Equipped with polyurethane wear-resistant friction wheels and an integrated mold structure for enhanced reliability.

Stable Support Rollers: Anti-slip rollers ensure secure and precise coil positioning during the wrapping process.

Versatile Material Compatibility: Handles a wide range of materials, including:

Woven tape

Kraft paper

Crepe paper

Non-woven fabric

Stretch film

PE, LLDPE, and HLDPE films

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

FPW-600 series wire coil wrapping machine seems like a great investment for companies that need to package pc wire and pre-strand wire coils. By saving labor costs and packaging materials, it can help companies to be more efficient and reduce their environmental impact.

The FHOPE FPW-600 Wrapping Machine is equipped with a loading and unloading cart that facilitates convenient material handling. It supports multi-layer wrapping and is compatible with a wide variety of packaging materials. This machine is primarily used for packaging metal coils. The equipment operates with high efficiency and safety, reducing both labor costs and packaging material consumption.

Features:

Optional automatic and semi-automatic working modes.

Equipped with wear-resistant polyurethane active and passive friction wheels and an integrated mold structure.

Anti-slip and safe support rollers ensure the packaging object is more stable and tidy.

Various packaging materials can be used, such as woven tape, kraft paper, crepe paper, non-woven fabric, stretch film, PE film, LLDPE film, HLDPE film, etc.

The large plate is adjustable, allowing the ring center height to be changed according to the coil specifications.

The overlap and tension of the packaging material can be adjusted according to customer requirements.

A manipulator device can be used for automatic feeding and cutting of packaging materials.

Optional movable cart device for more convenient coil packaging.

Special cutters and cylinders can cut various packaging materials.

Note: The equipment can be custom-designed according to your needs.

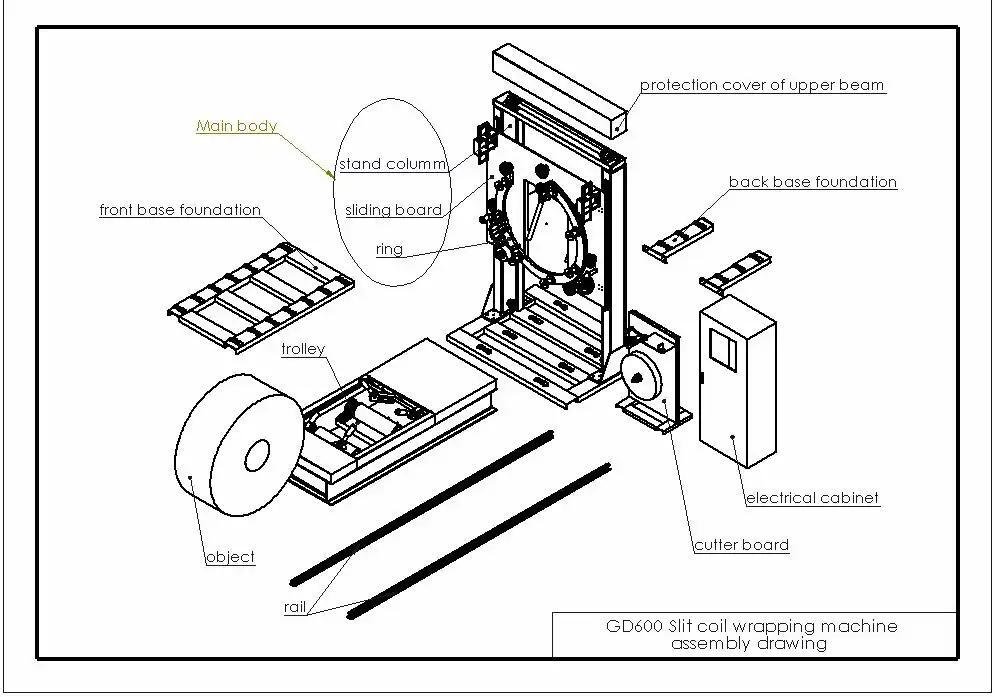

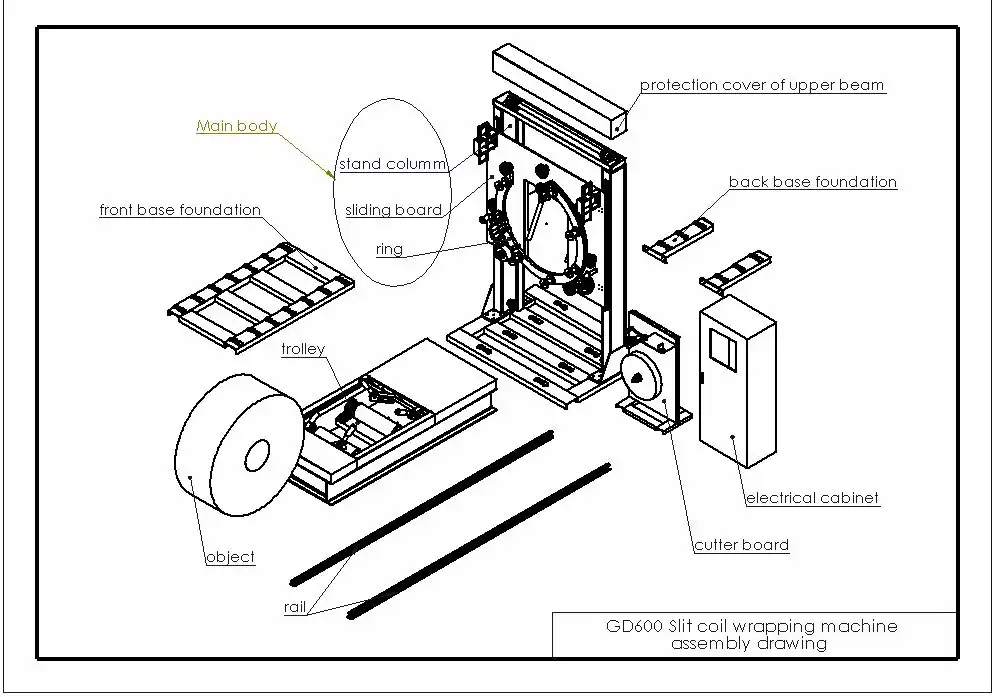

This machine is specially designed for unique packaging requirements, adaptable to various sizes of wire coils. It is equipped with a movable cart, adjustable large plate for lifting, automatic manipulator, and external feeding rack. The equipment is easy to operate with precise positioning. By combining support rollers and guide rollers, the material is automatically packaged and the packaging material is cut at the packaging station, effectively improving efficiency and quality. It is an ideal solution for packaging wire coils and other coiled materials.

| Technical parameter | |

| Model | FPW-600 |

| Power supply | 380v 50Hz 3Phase |

| Total power | about 2.5kw |

| OD | 700-1200mm |

| ID | >400mm |

| Width | 100-600mm |

| Weight | 100-3000kg |

| Packing material | PVC/LLDPE/PE/PAPER/HDPE |

| Packing material size | ID:50mm OD:100-450mm Width:90-120mm |

| Overlap rate | 10%-90% |

| Air supply | 4-6kgf/ ㎡ |

For more information, please contact us.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635