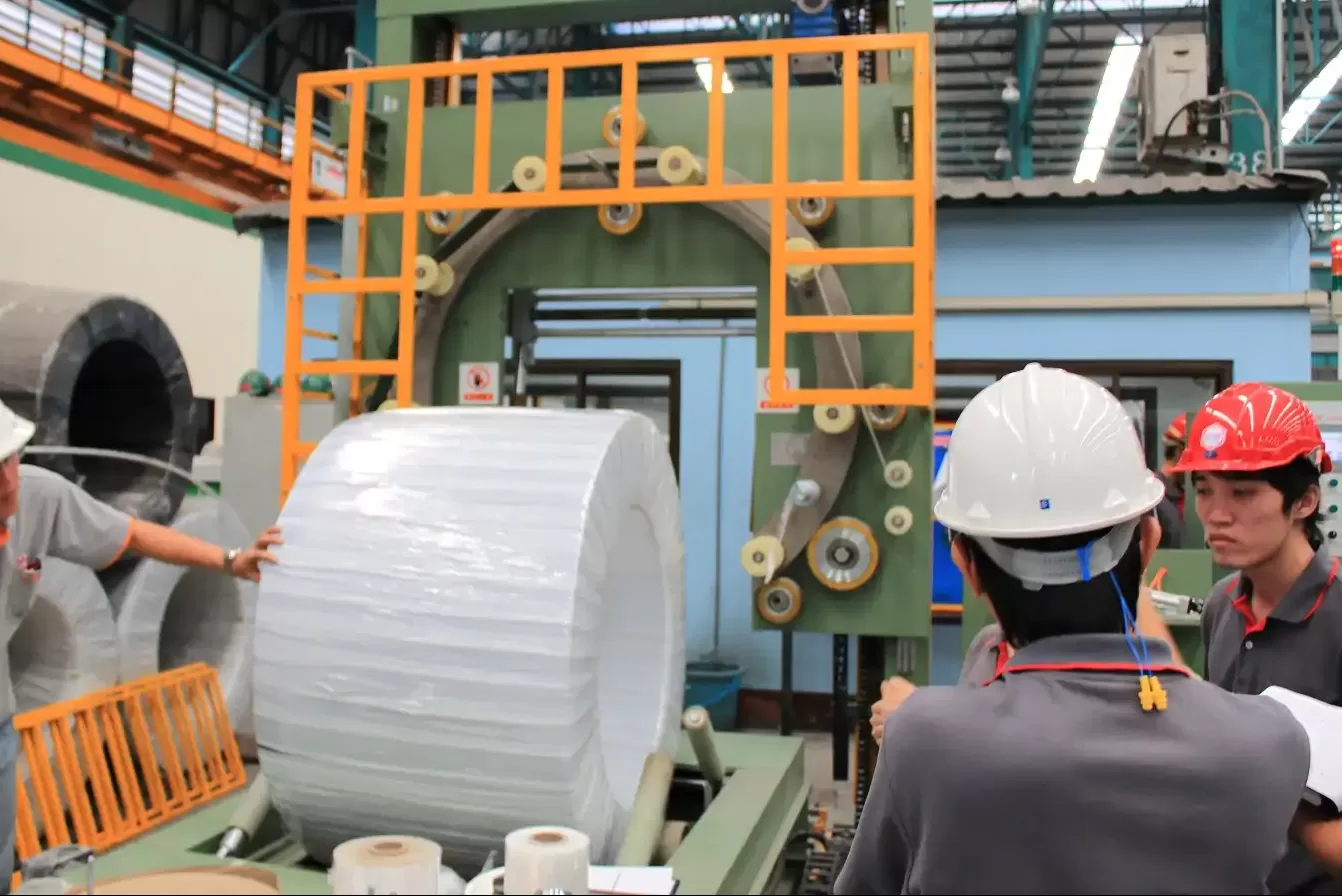

Wire coil wrapping machine FPW-400

This versatile machine is specifically designed for packaging steel wire coils, copper coils, tire bearings, and other ring-shaped items. It is a highly efficient device that reduces labor costs and packaging material usage while ensuring secure, consistent, and aesthetically pleasing packaging. With user-friendly operation and intelligent automation, it is the perfect solution for coil-shaped packaging needs.

Key Features:

Intelligent Control System: Equipped with PLC and a human-machine interface (HMI) for seamless operation and customization.

Streamlined Material Handling: Specialized system simplifies loading and unloading, saving time and effort.

Dual Operation Modes: Offers both manual and automatic modes, catering to diverse operational preferences.

Adjustable Ring Speed: Allows customization of packaging speed to suit material and packaging requirements.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

FPW series wire coil wrapping machine. It sounds like a useful and efficient piece of equipment for packaging steel wire coils and copper coils. The benefits you mentioned, such as saving labor, protecting the product, and reducing material costs, are important factors to consider when choosing packaging solutions for industrial products.

The equipment can be operated intelligently. All material data and details can be input into the control system. When switching to different packaging sizes, simply select the corresponding data on the screen, and the machine will automatically adjust to the appropriate packaging settings. This saves time, increases efficiency, and ensures good packaging quality. The relevant data are as follows:

Outer Diameter of the Material

Inner Diameter of the Material

Material Width

Material Weight

Packaging Speed

Number of Packaging Layers

The machine is mainly used for packaging steel wire coils, copper coils, tire bearings, and other ring-shaped objects.

It is a highly efficient packaging device for coil-shaped items, which helps save labor and packaging materials, effectively protects the packaged items, and is simple and safe to operate.

Product data can be entered into the machine, and the control system can automatically generate the optimal packaging method. Users can easily view and modify the packaging information through the touch screen.

Features:

Intelligent operation with PLC and human-machine interface.

Specialized system for easy material loading and unloading.

Easy-to-operate manual and automatic working modes.

Adjustable packaging ring speed.

Adjustable packaging material overlap rate.

Automatic packaging material cutting.

Smooth start and stop function to ensure safe operation.

Adjustable ring height according to the material.

Adjustable packaging tension.

Rollers are wrapped with polyurethane to protect the material surface.

Automatic alarm in case of malfunction, with fault display on the touch screen.

Special brake release device to prevent material folding.

Suitable for a wide range of packaging materials.

Note: Can be designed according to specifications.

| Technical parameter | |

| Model | FPW-400 |

| Power supply | 380v 50Hz 3Phase |

| Total power | about 1.5kw |

| OD | 600-1200mm |

| ID | >300mm |

| Width | 100-300mm |

| Weight | 50-500kg |

| Packing material | PVC/LLDPE/PE/PAPER/HDPE |

| Packing material size | ID:50mm OD:100-250mm Width:100-300mm |

| Overlap rate | 10%-90% |

| Air supply | 4-6kgf/ c㎡ |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635