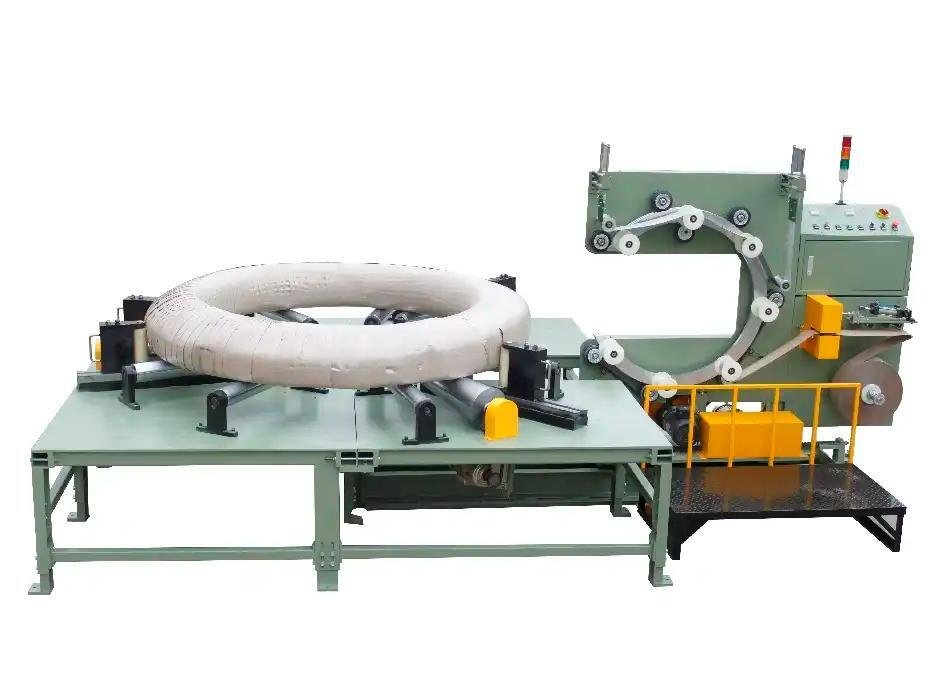

PC wire packaging machine

The Automatic Wrapping Station offers a seamless and efficient solution for coil wrapping, combining flexibility, safety, and advanced automation. It is designed to handle diverse packing needs while ensuring user convenience and optimal performance.

Key Features:

Flexible Operation Modes: Offers both manual and automatic modes for varied operational needs.

Smart Control System: Equipped with PLC and touch screen for intuitive, automated operation.

Easy Data Input: Simple input of coil dimensions (OD/ID/width) via the touch screen.

Taper Rollers: Facilitates smooth coil rotation during the wrapping process.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

A PC wire packaging machine streamlines the process of bundling and securing pre-stressed concrete wires for safe storage and transportation. Designed for precision and durability, it boosts operational efficiency, minimizes manual labor, and ensures consistent packaging quality, making it an essential tool in the construction materials industry.

Features:

Control Core: Equipped with an advanced PLC system, ensuring efficient and stable automated control.

Packaging Station: Integrated with a track system that supports smooth coil loading and unloading, optimizing the operation process.

Operating Modes: Offers flexible switching between manual and automatic modes, meeting the operational needs of different scenarios.

Power Adjustment: Integrated with an L-type inverter, which accurately adjusts the overlap of packaging material based on the real-time needs of the rollers and ring speed, enabling precise control.

Safety Protection: Equipped with safety barriers and soft start functionality to ensure a safe and worry-free operation process. The lifting design ensures both convenience and reliability.

Overload Protection: Features an internal overload protection mechanism that effectively prevents equipment damage due to overloading, extending the machine's lifespan.

Limiting System: Combines electrical and mechanical dual-limit systems to ensure safe operation within a predefined range.

Friction Adjustment: Adjustable friction between the friction wheel and the ring, adapting to the packaging needs of different materials.

Support Rollers: Motor-driven support rollers designed specifically for packaging protection, enhancing overall packaging quality.

Adjustable Tension: Tension during the packaging process can be adjusted according to actual needs, ensuring tight and aesthetically pleasing packaging.

Roller Material: The surface of the rollers is coated with polyurethane, offering wear resistance and protecting the packaged materials from damage during the process.

Rotating Ring Control: The rotating ring features soft start and stop functions, reducing impact and vibration, and supports ring reset functionality to ensure packaging precision.

Packaging Method: The material is fixed onto the ring for packaging, ensuring stability and consistency throughout the process.

High-Strength Packaging: Equipped with a special tension device tailored for high-strength packaging needs, enhancing overall packaging performance.

Fault Alarm: Built-in intelligent alarm system that automatically alerts and displays relevant information as soon as a fault is detected, enabling quick response and resolution.

Material Release Device: Uses a dedicated brake system that effectively prevents material folding issues during tape release, ensuring high-quality packaging.

Material Compatibility: Supports a variety of packaging materials, catering to diverse packaging needs.

| Parameter | Specification |

|---|---|

| Machine | PC wire packaging machine |

| Power supply | 380v 50Hz 3Phase |

| Total power | 3.8kw |

| OD | 1900-2200mm |

| ID | 1500-1800mm |

| Width | 100-220mm |

| Weight | 300-1500kg |

| Roller speed | 2-4米/分钟 |

| Packing material | PVC/LLDPE/PE/PAPER/HDPE |

| Overlap rate | 10%-90% |

| Ring speed | 20-60r/min |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635