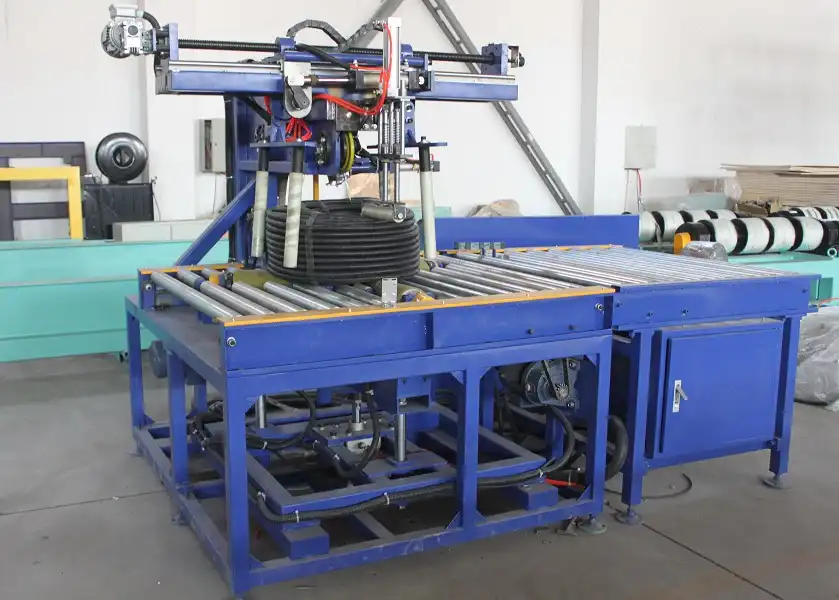

Horizontal steel coil wrapping machine FPCA-1000

The Automatic Wrapping Station offers a seamless and efficient solution for coil wrapping, combining flexibility, safety, and advanced automation. It is designed to handle diverse packing needs while ensuring user convenience and optimal performance.

Key Features:

Flexible Operation Modes: Offers both manual and automatic modes for varied operational needs.

Smart Control System: Equipped with PLC and touch screen for intuitive, automated operation.

Easy Data Input: Simple input of coil dimensions (OD/ID/width) via the touch screen.

Taper Rollers: Facilitates smooth coil rotation during the wrapping process.

Special Features

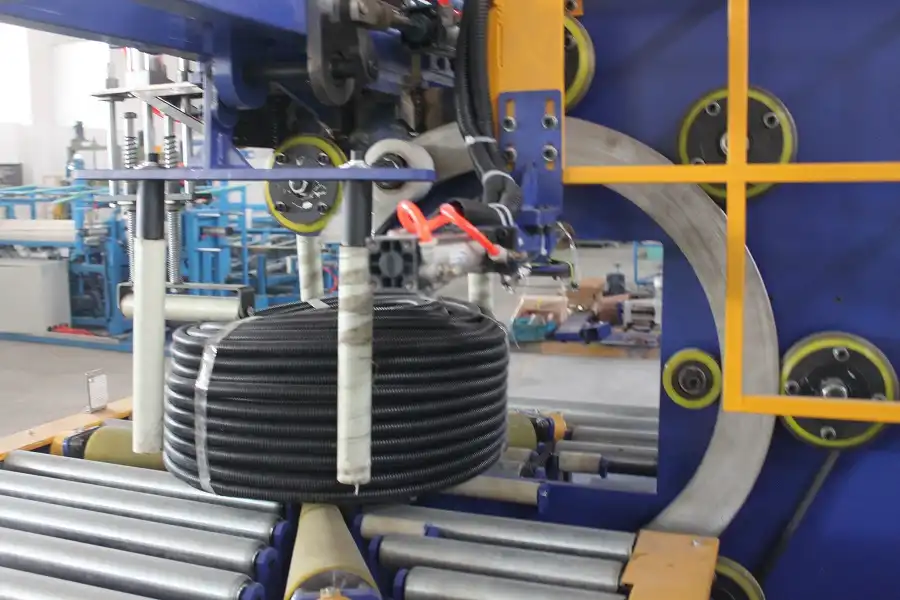

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The Horizontal Steel Coil Wrapping Machine FPCA-1000 is a high-performance packaging solution designed for secure and efficient wrapping of steel coils. Featuring advanced controls, durable materials, and customizable settings, it ensures optimal protection, reduces labor costs, and enhances packaging precision for heavy-duty industrial applications. Ideal for streamlining coil handling processes.

Automatic wrapping station

-

-Both Manual and Auto working modes can be choose for flexible operation.

-PLC and touch screen are good partner for packing’s automatic running.

-It’s simple to input coil’s OD/ID/width on the touch screen.

-Taper roller will help the coil rotation during wrapping process.

-Manual positioning for cost-effective budget.

-Automatic supportive rollers. Wrap tension adjustable as need.

-Frequency converter is great for machine’s speed adjustment.

-When it has various packing specification, it just inputs or adjusts some data on touch screen.

-Guardrails is necessary for safety.

-Guard roll is special design for coil’s convey leading ready for wrapping in place.

-Roller is made of stainless steel to keep steady and solid.

-The height of working table and conveyor is human engineering.

-For packing foil, the machine has nice management system of cutting off automatically.

-Also, manipulator for packing material’s feeding, clamping cutting optional.

-Friction of the ring is adjusted well when it’s delivery and it can adjust in site based on operator’s packing goal.

-Three-color safety light is topped on the electrical cabinet.

-The machine has good running habit of soft start and soft stop.

-Conveyor length can be made according to need.

-Height of conveyor table adjustable 880-890mm Work table total width 1200mm (net 1100mm inside between 2 channel width 50mm)control panel should be touched and controlled the operator side over the machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635