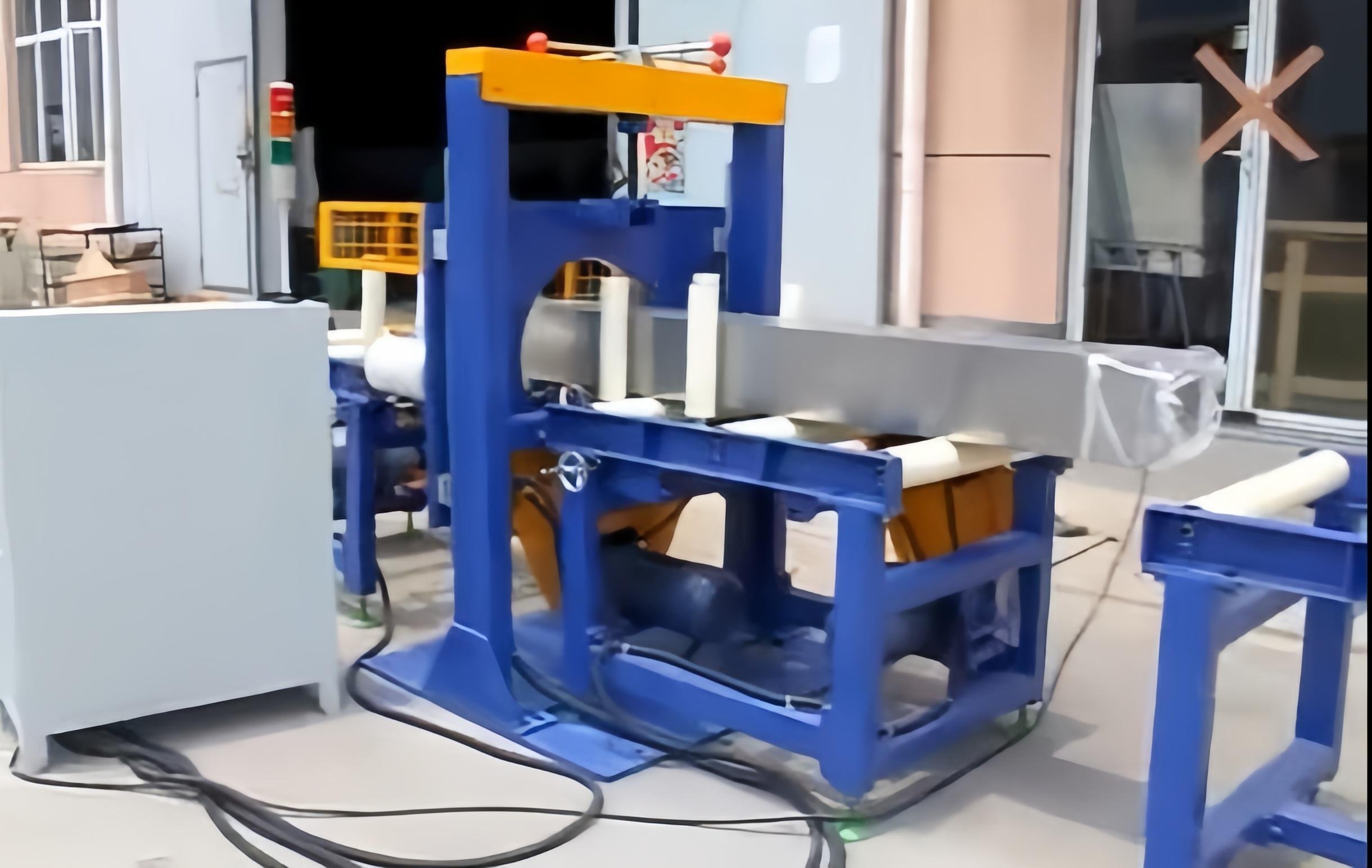

Semiauto horizontal orbital wrapping machine S100

The Semi-Automatic Orbital Stretch Wrapper is a reliable and efficient solution for wrapping horizontal products like pipes, bars, and floorboards. Its adaptable design ensures secure and professional packaging, making it ideal for various industries.

Key Features:

Ring-Type Wrapping: Delivers consistent and even coverage.

Adjustable Tension & Overlap: Customizable for different wrapping needs.

Soft Start/Stop: Ensures smooth operation and longer machine life.

PU-Covered Rollers: Protects product surfaces during handling.

Safety Guardrails: Enhances operator safety during operation.

Special Features

Related video

The Semiauto Horizontal Orbital Wrapping Machine S100 is ideal for lightweight and compact product packaging. Designed for semi-automatic operation, it delivers consistent wrapping results with adjustable settings. Its durable construction and user-friendly interface make it a practical solution for industries seeking cost-effective and efficient packaging options.

Semi-Automatic Orbital Stretch Wrapper

Overview

The Semi-Automatic Orbital Stretch Wrapper is a highly versatile packaging solution designed to handle a wide range of product types, shapes, and sizes. Its adaptability makes it an ideal choice for diverse industries requiring efficient and reliable wrapping. Whether used for pipes, bars, floorboards, or other horizontal items, this machine ensures secure, professional, and tidy packaging, enhancing both protection and product appearance.

Key Features

Wrapping Station

The wrapping station is engineered for precision and user convenience, incorporating advanced features to meet various packaging requirements:

Ring-Type Stretch Wrapping Machine: Ensures even and consistent wrapping for products of various dimensions.

Adjustable Drive Friction and Wheels: Enhances operational stability and adaptability to different materials.

Inverter-Controlled Ring Speed: Allows precise speed adjustments, ensuring optimal wrapping performance.

Soft Start and Stop: Reduces mechanical stress, ensuring smooth operation and extended machine lifespan.

Resettable Ring Initial Point: Simplifies operation by allowing easy resetting to the starting position.

Adjustable Packing Material Tension: Provides flexibility for different product wrapping needs.

Compatibility with Various Packing Materials: Offers versatility for different industries and products.

Safety Guardrails: Ensures secure and safe operation by preventing accidental access to moving parts.

Overlap Control (10%-90%): Customizable overlap settings to achieve the desired level of packaging coverage.

Conveyor System

The conveyor system enhances the overall efficiency of the wrapping process by automating the movement of products:

PU-Covered Rolls Conveyor: Protects the surface of delicate products during transportation.

Automatic Entrance and Outlet Conveyor Systems: Streamlines product flow into and out of the wrapping station.

Conveyor Adjustment Function: Allows customization to suit different product dimensions and specifications.

Motor-Driven Conveyors with Gearbox: Provides reliable and consistent movement for seamless operation.

Adjustable Conveyor Speed via Inverter: Offers flexibility to match the speed of production lines and specific packaging requirements.

Benefits

Adaptability: The machine is designed to handle a variety of product shapes, sizes, and materials, making it ideal for almost any application.

Precision Wrapping: Features like inverter-controlled speed, adjustable tension, and overlap customization ensure high-quality, consistent wrapping results.

Enhanced Safety: Guardrails and safety-focused features provide a secure operating environment.

Surface Protection: PU-covered rollers and controlled handling prevent damage to product surfaces, ensuring a professional finish.

Efficiency: The combination of automatic conveyor systems and motor-driven components reduces manual intervention, increasing productivity and efficiency.

Why Choose This Solution?

The Semi-Automatic Orbital Stretch Wrapper offers unparalleled flexibility and reliability for businesses looking to improve packaging efficiency while maintaining product quality. Its advanced features, safety mechanisms, and adaptability to various applications make it a cost-effective and valuable investment for any production line.

| Parameter | Specification |

|---|---|

| Object Size | Bundle OD: 50-200mm |

| Length | >1500mm |

| Entrance Conveyor Length | 1000mm with motor |

| Outlet Conveyor Length | 1000mm with motor |

| Speed | 4~15m/min |

| Ring Speed | 20-100r/min |

| Power | About 1.5kw |

| Voltage | AC 380v, 60Hz |

| Materials | LLDPE stretch film/PE/HDPE |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635