Semiauto horizontal orbital wrapping machine S300

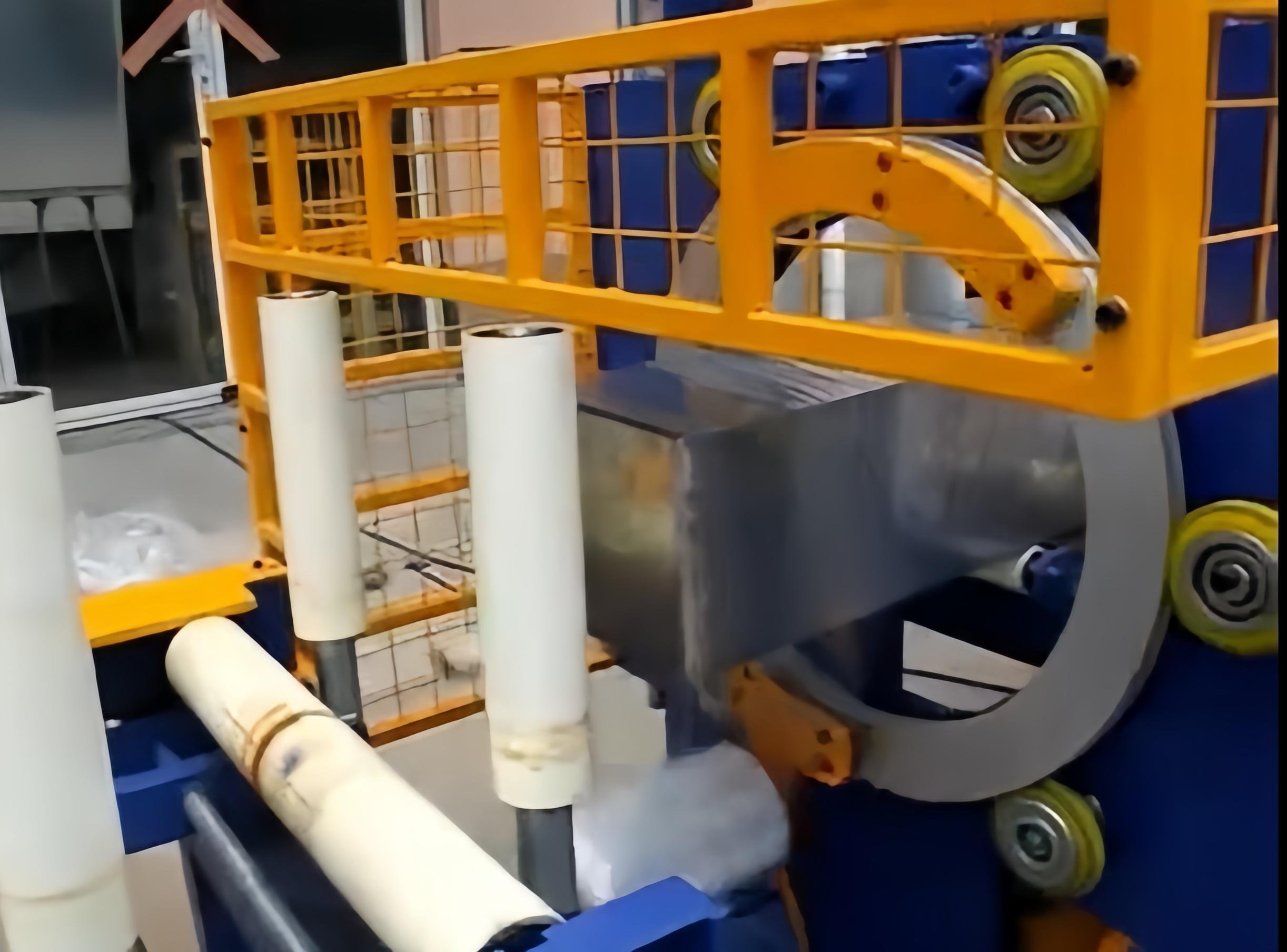

The Semi-Automatic Horizontal Stretch Wrapper is engineered for precision and ease, making it ideal for wrapping horizontal products like pipes, tubes, bars, and floorboards. Its robust design ensures protection, a professional finish, and operational efficiency for various industries.

Key Advantages

Effortless Setup: Requires only a power and air connection for quick installation.

Reliable Safety: Friction wheels enhance stability, ensuring smooth, accident-free operation.

Advanced Automation: PLC interface with photoelectric sensors for precise, hands-free wrapping.

Customizable Performance: Adjustable overlap rate and tension for tailored wrapping solutions.

Product Stability: Support rollers securely hold items, preventing movement during wrapping.

Special Features

Related video

The Semiauto Horizontal Orbital Wrapping Machine S300 is designed for versatile and efficient wrapping of elongated or irregular items. It combines semi-automatic operation with adjustable settings, ensuring reliable performance across diverse applications. Built for durability and ease of use, the S300 enhances packaging protection while optimizing productivity in industrial environments.

Semi-Automatic Horizontal Stretch Wrapper

Comprehensive Overview

The Semi-Automatic Horizontal Stretch Wrapper is a versatile and reliable solution for wrapping a wide range of horizontal products such as pipes, tubes, bars, floorboards, and more. Engineered for precision and efficiency, this machine ensures the wrapped items are not only well-protected and sealed but also look professional and tidy, making them ideal for transport and storage.

Constructed with a lightweight yet robust aluminum alloy wrapping ring, the machine provides high-speed, accurate rotation while maintaining durability. Its special PU wheels with bearings allow for adjustable traction, ensuring stable, smooth, and consistent wrapping across all operations. The user-friendly design simplifies film loading and insertion, while the roll carriage includes locking and quick-release features for effortless operation.

Key Advantages

Effortless Installation

Setup is quick and hassle-free, requiring only a power supply and air connection to get started. This simple installation process minimizes downtime and ensures the machine is ready for operation with minimal preparation.

Reliable Safety and Stability

The integrated friction wheel device enhances operational safety and stability, ensuring smooth performance even during high-speed wrapping. This reduces the risk of accidents and operational inconsistencies.

Advanced Automation Features

Equipped with a PLC man-machine interface, the machine provides intuitive controls for seamless operation. The photoelectric sensor system ensures precise positioning, reducing manual input and increasing overall accuracy.

An automatic alarm system detects and alerts operators to any malfunctions, promoting timely troubleshooting and minimal interruptions.

Customizable Wrapping Performance

The overlap rate is fully adjustable, allowing the machine to cater to a variety of wrapping needs, whether for tight seals or lighter protective wraps.

Operators can fine-tune the wrapping tension, ensuring the perfect balance between protection and efficiency for different products.

Enhanced Product Stability

Designed with support rollers and positioning rollers, the machine securely holds products in place during the wrapping process. This prevents shaking or movement, ensuring a flawless and consistent wrapping result every time.

Streamlined Maintenance

Routine maintenance is simplified, requiring minimal effort. The thoughtful design reduces the time and costs associated with maintaining the machine, ensuring it remains in optimal working condition over the long term.

High-Efficiency Packaging

The automatic clamping and cutting device for packaging materials enhances productivity by reducing manual intervention. This feature ensures a seamless and efficient workflow, even in high-demand production environments.

Expanded Features

Lightweight Wrapping Ring

Made from aluminum alloy, the wrapping ring combines strength and lightweight properties. Its durability allows it to endure frequent use, while its precision design ensures smooth, high-speed operation for consistently excellent results.PU Wheel with Adjustable Traction

The use of special PU wheels with bearings enhances the stability and adaptability of the wrapping process. These wheels provide precise control over traction, allowing operators to adjust settings to match product requirements and ensure stable wrapping.Simplified Film Handling

The roll carriage features a locking mechanism and quick-release system, enabling operators to load and replace wrapping film with ease. This user-friendly design minimizes downtime and ensures uninterrupted production.Versatile Applications

The machine is ideal for a wide range of horizontal products, making it suitable for industries like construction materials, steel pipes, furniture manufacturing, and more. It delivers a uniform, professional finish that enhances the appeal of wrapped goods.

Why Choose the Semi-Automatic Horizontal Stretch Wrapper?

The Semi-Automatic Horizontal Stretch Wrapper stands out as an essential tool for businesses seeking efficient, reliable, and high-quality packaging solutions. With its advanced automation features, customizable settings, and user-friendly design, this machine delivers unmatched performance for horizontal wrapping tasks.

Whether you’re focused on improving operational efficiency, reducing labor costs, or ensuring the professional appearance of your products, this machine is a valuable investment that supports long-term productivity and success.

Technical Parameter S300

| Parameter | Specification |

|---|---|

| Length | >1000mm |

| OD | 50-300mm |

| Entrance Conveyer Length | 2000mm |

| Outlet Conveyer Length | 2000mm |

| Ring Speed | 100r/min |

| Power Output | app. 1.5kw |

| Power Voltage | AC 380v, 60Hz |

| Material | Stretch film Width: 120mm OD: 250mm ID: 50mm |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635