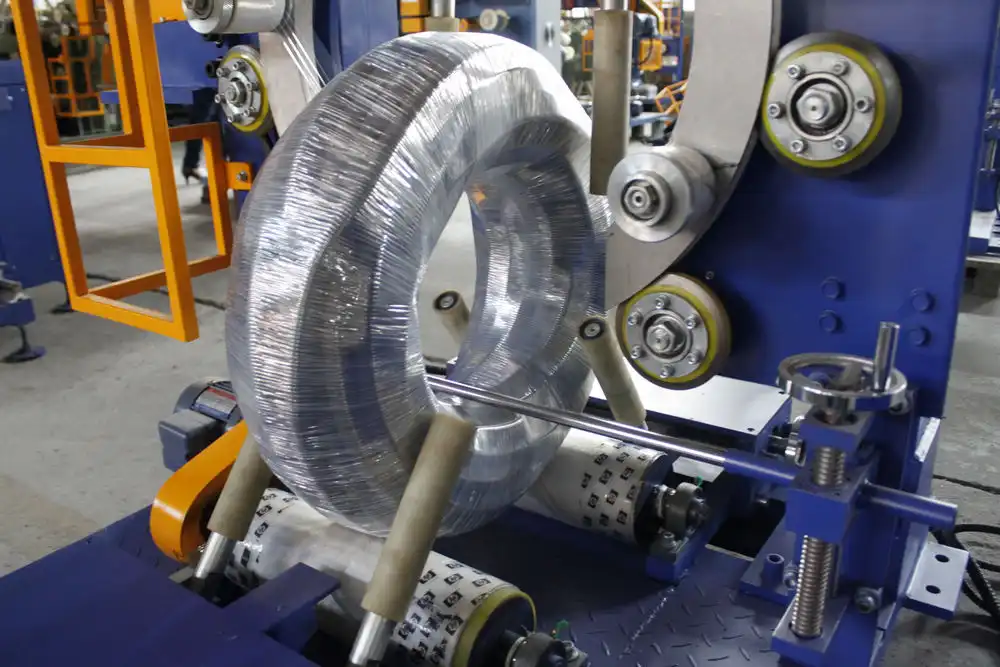

HDPE pipe packing machine

The vertical winding packaging machine is an advanced solution specifically designed for packaging HDPE hose coils, addressing the challenges associated with both light and heavy coiled materials. Its user-friendly vertical design with the opening facing upward simplifies feeding and discharge processes, making it ideal for efficient and reliable operation.

Key Features

Vertical Design:

The upward-facing opening streamlines material feeding and discharge, enhancing operational convenience.

Material Versatility:

Capable of handling both light and heavy HDPE hose coils with precision.

Durable Packaging:

Ensures hose coils are securely wrapped, preventing damage during storage and transportation.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The vertical winding packaging machine specially designed for fhose of hdpe coiled materials is introduced, which can be applied to light and heavy coiled materials. The design with the opening facing up is convenient for feeding and discharging, and convenient for operation.

Vertical Winding Packaging Machine: Efficient Packaging for HDPE Hose Coils

The Vertical Winding Packaging Machine is a specialized solution designed to package HDPE (High-Density Polyethylene) hose coils efficiently and effectively. By addressing the challenges associated with packaging light and heavy coiled materials, this machine ensures durability, convenience, and precision in wrapping, making it an essential tool for industries that handle HDPE hose coils.

Key Features of the Vertical Winding Packaging Machine

Vertical Design with Upward-Facing Opening

Simplifies the feeding and discharge process, ensuring smooth handling of hose coils.

Provides a user-friendly operation for easy setup and maintenance.

Versatility for Different Coil Types

Capable of handling both light and heavy coiled materials, making it suitable for various applications.

Designed specifically for HDPE hose coils, accommodating their unique flexibility and strength.

Streamlined Packaging Process

Automates the wrapping process to reduce manual effort and improve efficiency.

Ensures consistent and secure packaging for both storage and transportation.

Benefits of the Vertical Winding Packaging Machine

Improved Product Protection

Wraps HDPE hose coils securely to protect them from damage, dust, and moisture.

Reduces the risk of deformation or tangling during storage and transit.

Enhanced Efficiency

Speeds up the packaging process, allowing for higher throughput and productivity.

Minimizes labor costs by automating repetitive tasks.

Durability and Reliability

Built to handle the demands of packaging large and heavy coils, ensuring long-term performance.

Cost-Effective Operation

Optimizes material usage and reduces waste, lowering overall packaging costs.

Reduces downtime with easy-to-operate and maintain systems.

Custom-Tailored Solutions

Designed to meet the unique challenges of HDPE hose coil packaging, providing a reliable and scalable solution for various industry needs.

Applications

The Vertical Winding Packaging Machine is ideal for industries that produce and handle HDPE hose coils, including:

Construction: Packaging durable HDPE hoses for use in construction sites.

Agriculture: Securing irrigation hoses for storage and distribution.

Manufacturing: Ensuring industrial HDPE hoses are safely packaged for transportation.

Why Choose the Vertical Winding Packaging Machine?

This machine is specifically engineered to meet the demands of packaging HDPE hose coils, addressing their unique challenges with precision and efficiency. Key advantages include:

Streamlined operations with user-friendly design and automated functionality.

Enhanced protection for hose coils during storage and transportation.

Cost savings through optimized material usage and reduced labor.

By investing in the Vertical Winding Packaging Machine, businesses can ensure secure and efficient packaging of HDPE hose coils, improve operational efficiency, and reduce overall costs, making it a valuable addition to any production line.

| Specification | Details |

|---|---|

| Machine Model | FPH-200 Coil Wrapper |

| Voltage (V/Hz) | AC 380/50 (or your requirement) |

| Power (KW) | 1.5 |

| Coil Inner Diameter (ID) | 300-600 mm |

| Coil Outer Diameter (OD) | 400-900 mm |

| Coil Width | 50-200 mm |

| Coil Weight | 5-50 kg |

| Packing Material | LLDPE/PE/Stretch film/PVC |

| Ring Speed (r/min) | 20-90 |

| Wrapping Speed | 15-35 sec/pcs |

| Overlapping Rate | 20-90% |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635