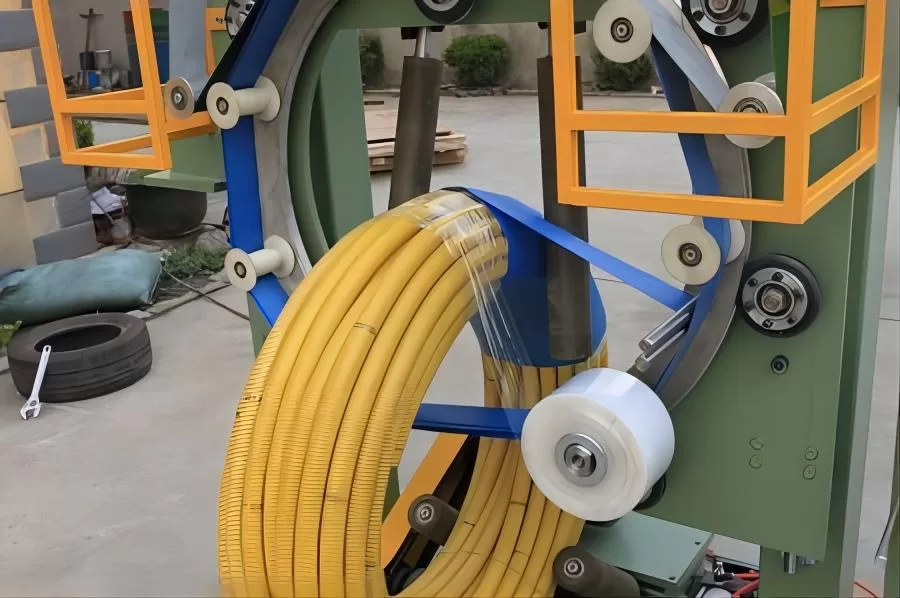

Coil wrapper FPH-400

The FPH series coil wrapper is a versatile and efficient machine designed for wrapping small and light coils, such as hose coils, PEX pipes, and plastic pipes. With its vertical design and advanced features, it offers ease of operation, reliable performance, and significant cost savings.

Advantages

Cost Savings:

Reduces labor and material costs through automation and efficient operation.

Enhanced Product Protection:

Reliable wrapping prevents contamination and ensures durability during transit.

Ease of Use:

User-friendly design and adjustable settings allow seamless operation for varied requirements.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The FPH-400 coil wrapper is a high-performance machine designed for efficient and secure wrapping of coils. It provides excellent protection against dust, moisture, and damage during storage or transportation. Featuring advanced automation, it ensures consistent wrapping quality while improving productivity. Compact and versatile, it suits various industrial packaging requirements.

FPH Series Coil Wrapper: Efficient Solutions for Small and Light Coils

The FPH Series Coil Wrapper is a specialized machine designed to efficiently wrap small and light coils, such as hose coils, PEX pipes, and plastic pipes. Its vertical design ensures ease of operation and maintenance, making it a user-friendly choice for industries seeking to enhance packaging efficiency while reducing labor and material costs.

Features and Benefits of the FPH Series Coil Wrapper

Vertical Design for Easy Access

Simplifies operation and maintenance, allowing for quicker adjustments and servicing.

Versatile Applications

Coils of wire, hose, cable, and plastic pipes.

Products from industries such as manufacturing, packaging, and distribution.

Suitable for wrapping various products, including:

Manual and Automatic Modes

Dual operation modes provide flexibility for different applications and production needs.

Advanced Wrapping Controls

Equipped with sensors for positioning to ensure accurate and consistent wrapping.

Includes an inverter for speed control, enabling precise wrapping to match specific requirements.

Adjustable overlap rate for customizable protection levels depending on material and application.

Protective Features

Soft start and stop functions reduce wear and prolong machine lifespan.

Guiding rollers protect coils and ensure proper alignment during wrapping.

Pre-Wrapping Adjustment

A special breaker allows adjustments to the wrapping process before it begins, ensuring consistent results.

Automatic Indicators and Alarms

Real-time monitoring system alerts operators to potential issues, enhancing reliability and minimizing downtime.

Cost-Effective Packaging

High-speed and efficient wrapping save both time and resources, delivering a rapid return on investment.

Compatible Materials for Wrapping

LLDPE and PVC

Ideal for protecting products from air, moisture, and dust, ensuring durability and contamination prevention.

HDPE and PE

Durable and abrasion-resistant materials, suitable for products exposed to wear during transportation.

Material Selection

Choosing the appropriate material depends on the product’s requirements, such as storage conditions, transportation, and environmental exposure.

Factors to Consider When Choosing a Coil Wrapping Machine

Size and Weight of Products

Ensure the machine can handle the specific dimensions and weight of your products.

Desired Level of Automation

Evaluate whether manual, semi-automatic, or fully automatic modes best suit your production needs.

Budget and ROI

Balance the machine’s cost with its potential to reduce labor and material expenses.

Material Requirements

Select a machine compatible with the packaging materials that best protect your products.

Operational Features

Look for features like adjustable speed, overlap rate, and safety measures for enhanced efficiency and longevity.

Applications

The FPH Series Coil Wrapper is ideal for industries such as:

Manufacturing: Wrapping hoses, pipes, and wires for storage or transportation.

Packaging: Securing light coils in protective materials.

Distribution: Ensuring product integrity during transit.

Why Choose the FPH Series Coil Wrapper?

The FPH Series Coil Wrapper offers:

High Efficiency: Reduces labor and material costs with automated processes.

Reliability: Ensures consistent and accurate wrapping with advanced features.

Versatility: Adapts to a variety of product sizes and packaging materials.

Durability: Designed for long-term use with protective features and robust construction.

By integrating this solution, businesses can achieve faster packaging times, improved product protection, and significant cost savings, making it a valuable addition to any production line.

| Specification | Details |

|---|---|

| Machine Model | FPH-400 Coil Wrapper |

| Voltage (V/Hz) | AC 380/50 (or your requirement) |

| Power (KW) | 1.8 |

| Coil Inner Diameter (ID) | 400-800 mm |

| Coil Outer Diameter (OD) | 500-1200 mm |

| Coil Width | 50-400 mm |

| Coil Weight | 3-25 kg |

| Packing Material | LLDPE/PE/Stretch film/PVC |

| Ring Speed (r/min) | 20-90 |

| Wrapping Speed | 15-35 sec/pcs |

| Overlapping Rate | 20-90% |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635