95 °Pallet Exchanger

The 95° pallet tipper is an essential tool in logistics and warehousing, designed to securely tip or exchange pallets loaded with goods. Powered by a hydraulic system, it streamlines operations, reduces reliance on manual labor, and minimizes workplace injury risks. Widely used in industries like warehousing, manufacturing, and retail distribution, this equipment significantly improves productivity and ensures a better return on investment.

Model: FPFZ-01L

Max Loading: 1000–2000 Kg

Changing Speed: 20–35 Seconds

Turning Degree: 90–95°

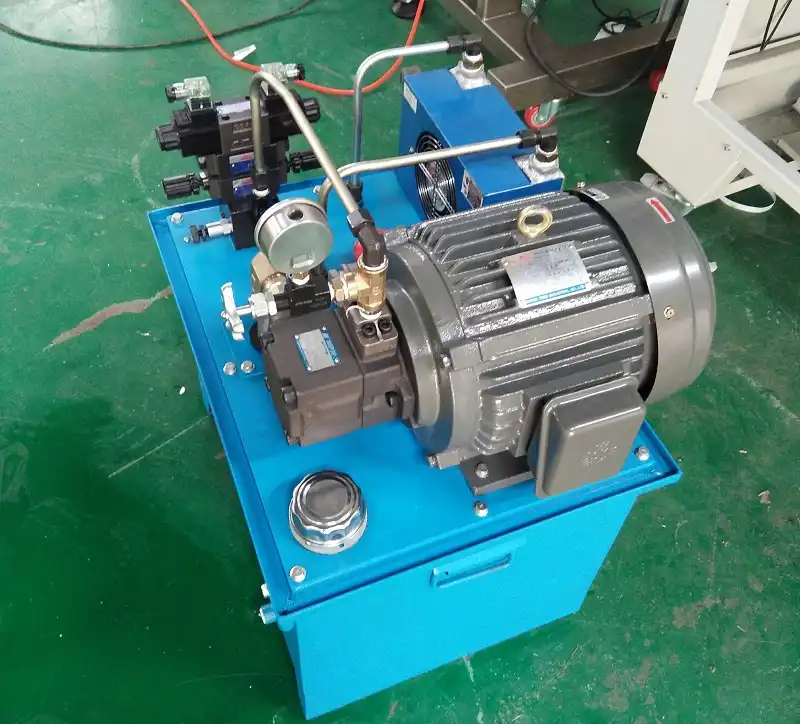

Driving System: Hydraulic System

Control Options: Panel/Remote Control

Special Features

Fast and Precise Pallet Exchange

Streamlines the process of replacing damaged or incorrect pallets, saving time and improving productivity.

Versatile Pallet Compatibility

Accommodates a wide range of pallet types and sizes, ensuring seamless integration with existing workflows.

Ergonomic and Easy Operation

Features user-friendly controls and automated systems, reducing physical strain on operators and increasing ease of use.

Related video

A 95° pallet exchanger is a specialized device designed to tilt pallets at a 95-degree angle, enabling efficient pallet replacement or load transfer. It enhances workplace safety, streamlines material handling, and minimizes manual effort, making it an ideal solution for industries requiring frequent pallet changes or reorientation.

Enhancing Logistics Efficiency with 95-Degree Pallet Tippers

In the complex world of logistics and warehousing, efficient material handling is critical for ensuring productivity and workplace safety. Among the many tools designed to streamline these operations, the 95-degree pallet tipper stands out as an indispensable asset. This advanced machinery is specifically designed to securely tip, rotate, and exchange pallets loaded with goods, significantly reducing dependence on manual labor.

By automating the pallet-handling process, businesses can not only accelerate their workflows but also mitigate workplace injuries, fostering a safer and more efficient environment. In this article, we delve into the functionalities, benefits, and applications of 95-degree pallet tippers, providing valuable insights to help businesses make informed decisions when selecting the right model for their needs.

Key Features and Specifications of a 95-Degree Pallet Tipper

Understanding the technical aspects of a 95-degree pallet tipper is essential for evaluating its suitability for various operational demands. Below is an expanded and well-organized table highlighting the key parameters of a typical model:

| Parameter | Specification |

|---|---|

| Model | FPFZ-01L |

| Length | 1000–1200 mm |

| Width | 1000–1200 mm |

| Height | 1000–2000 mm |

| Maximum Loading | 1000–2000 kg |

| Changing Speed | 20–35 seconds |

| Turning Degree | 90–95° |

| Driving System | Hydraulic system |

| Control Options | Panel or remote control |

| Power Requirement | 4.5 KW |

| Safety Features | Protective fence, light beam sensors |

Enhanced Functionality and Benefits

Why Choose a 95-Degree Pallet Tipper?

Improved Efficiency

The hydraulic system ensures swift pallet tipping, enabling the machine to handle loads within 20 to 35 seconds. This drastically reduces downtime and enhances throughput in busy warehouse operations.Enhanced Safety

Equipped with advanced safety measures like protective fences and light beam sensors, the 95-degree pallet tipper minimizes risks to operators and other personnel, ensuring compliance with workplace safety regulations.Flexible Control Options

The machine offers intuitive control via control panels or remote systems, allowing operators to manage tasks from a safe distance. This versatility ensures ease of use and adaptability in various environments.High Load Capacity

With a maximum load capacity of up to 2000 kg, this equipment is suitable for heavy-duty operations, making it an ideal choice for industries like manufacturing, logistics, and retail distribution.Space Optimization

The compact design, combined with its adjustable dimensions (length, width, and height ranging from 1000 to 2000 mm), makes it a perfect fit for facilities with limited space.

Applications Across Industries

The 95-degree pallet tipper finds utility in a diverse range of industries, including:

Warehousing: Simplifies pallet exchanges and minimizes manual handling, improving overall operational efficiency.

Manufacturing: Assists in safely rotating pallets containing delicate or hazardous materials.

Retail and Distribution: Streamlines the process of loading and unloading goods, ensuring faster turnover.

Food and Beverage: Safely handles pallets of perishable goods, reducing spoilage and maintaining hygiene standards.

Automotive: Ideal for managing heavy parts or components, ensuring safe and precise handling.

Choosing the Right Model for Your Needs

When selecting a 95-degree pallet tipper, consider factors such as:

Load Requirements: Evaluate the maximum weight capacity (1000–2000 kg) based on your operational needs.

Safety Standards: Ensure the model includes adequate safety features, such as protective fences and light beams.

Operational Speed: Opt for a machine with a faster changeover time (20–35 seconds) to match your workflow demands.

Control Preferences: Decide between panel-based or remote control systems depending on your workspace layout.

Energy Efficiency: Check the power consumption (4.5 KW) and ensure it aligns with your facility's energy goals.

Final Thoughts

Investing in a 95-degree pallet tipper is a strategic move for businesses aiming to enhance material handling efficiency while maintaining high safety standards. With its robust features, adaptable design, and broad applications, this equipment can significantly boost productivity across various industries. By understanding your specific requirements and comparing available models, you can choose the perfect pallet tipper to optimize your operations and achieve long-term cost savings.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635