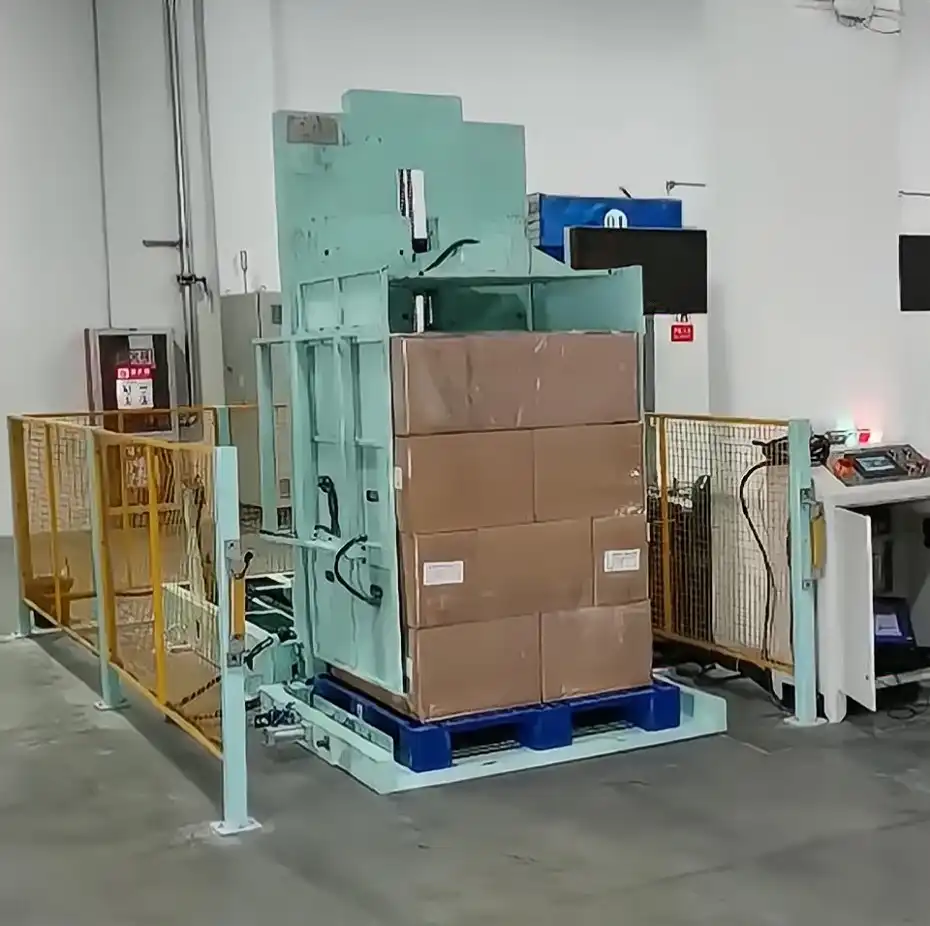

Pallet Changing Machine

The upgraded Fhope 95-degree pallet exchanger simplifies pallet handling with a space-saving design and automatic operation. It allows floor-level loading using pallet trucks or forklifts, making it ideal for fragile goods like ceramics and glass bottles. With a compact footprint and versatile functionality, it ensures safe, efficient, and fast pallet exchange, supporting a wide range of pallet sizes.

Maximum Loading: 2000 Kg

Drive System: Hydraulic

Pallet Dimensions: L500–1200 mm × W500–1200 mm × H500–2000 mm

Loading Equipment: Pallet Truck or Forklift

Special Features

Fast and Precise Pallet Exchange

Streamlines the process of replacing damaged or incorrect pallets, saving time and improving productivity.

Versatile Pallet Compatibility

Accommodates a wide range of pallet types and sizes, ensuring seamless integration with existing workflows.

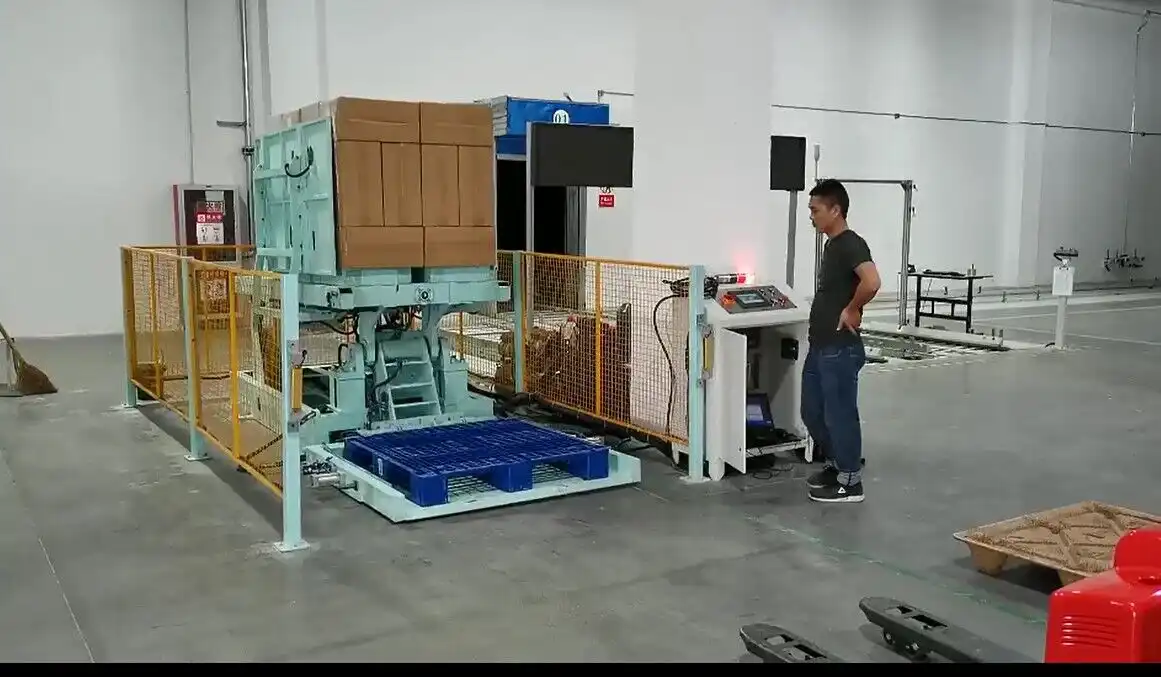

Ergonomic and Easy Operation

Features user-friendly controls and automated systems, reducing physical strain on operators and increasing ease of use.

Related video

A pallet changing machine is a versatile industrial device designed to streamline pallet replacement processes. It enhances efficiency by quickly swapping loaded pallets without manual handling, reducing labor costs and operational downtime. Ideal for industries requiring high-speed logistics, it ensures safe, reliable, and seamless pallet changes, optimizing workflow and improving productivity.

Fhope 95-Degree Pallet Exchanger: A Revolutionary Upgrade for Efficient Pallet Handling

The Fhope 95-degree pallet exchanger has undergone significant upgrades to simplify and streamline the pallet exchange process. This innovative machine now features an advanced mechanism that allows pallets to be lifted up and down, making it accessible for loading and exchanging using a pallet truck at floor level. This design is particularly ideal for scenarios where equipment lacks loading capabilities.

Key Features and Benefits of the Pallet Exchanger

Steady and Smooth Operation

The machine ensures a stable and seamless operation, providing reliable support for fragile goods such as ceramics and glass bottles.Space-Saving Design

With its compact design, this pallet exchanger minimizes space requirements while optimizing workflow, making it suitable for limited spaces.Simplified Pallet Exchange

Designed for user convenience, it reduces labor intensity and streamlines the entire pallet-changing process.Versatile Applications

The machine accommodates a wide range of pallet sizes, from small to large, offering solutions for various industries.

Enhanced Loading and Operation Capabilities

Easy Loading: Handles large and heavy pallets with floor-level feeding using a pallet truck or forklift.

Automatic Operation: A simple button press completes the pallet exchange process automatically, reducing manual intervention.

Operator Safety: Safety barriers isolate the machine from operators during operation to prevent accidents.

Quick Exchange: Pallets are exchanged efficiently, minimizing downtime and increasing productivity.

Flexible Size Range: The machine supports pallet heights ranging from 600mm to 2000mm, ensuring compatibility with diverse requirements.

Technical Specifications

| Parameter | Details |

|---|---|

| Maximum Loading | 2000 kg |

| Drive System | Hydraulic |

| Pallet Dimensions | Length: 500–1200 mm; Width: 500–1200 mm; Height: 500–2000 mm |

| Loading Equipment | Pallet truck or forklift |

Advanced Features for Diverse Needs

Supports Tilted and Fragile Loads: The machine secures and straightens feebly accumulated or tilted loads, such as ceramics or glass bottles.

Hygienic Material Handling: Easily switch between raw materials and hygienic plastic or wooden pallets, making it ideal for in-house operations.

Damage Restoration: Effectively handles damaged or fragmented pallets, ensuring safety and smooth operations on tracking systems.

Why Choose Fhope?

The Fhope team specializes in designing and manufacturing customized tilting equipment tailored to your workspace. Our experts work closely with you to understand your specific layout and handling needs, delivering solutions that maximize efficiency in limited spaces. With our commitment to research and development, we continuously enhance our technology to meet evolving market demands.

By combining safety, efficiency, and innovative engineering, Fhope's 95-degree pallet exchanger offers a comprehensive solution for modern industries looking to optimize their pallet handling operations.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635