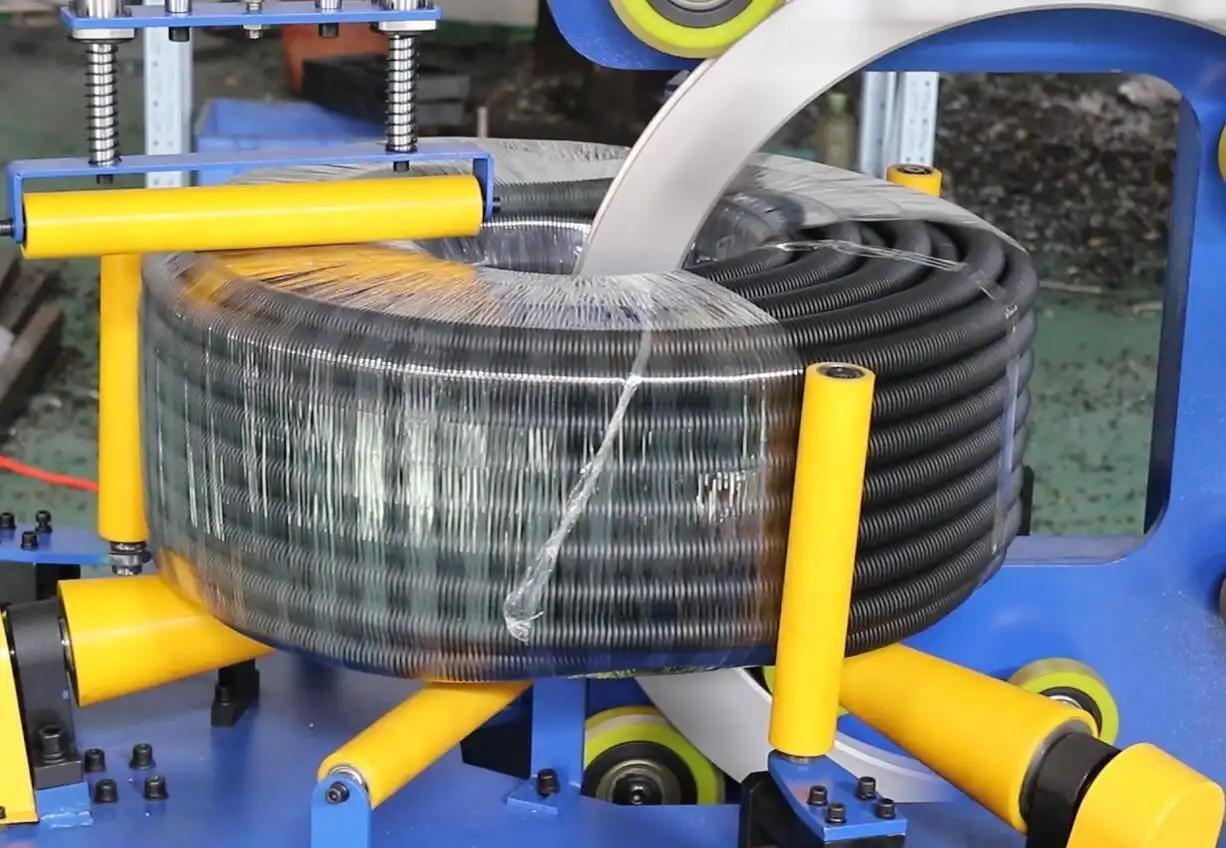

Corrugated hose wrappinging machine FPCA100

The FPH Series Hose Wrapping Machine by Fhope Machinery is an advanced, automated solution for efficient and reliable hose packaging. Designed for industries like plastic and rubber pipes, metallurgy, and more, this machine offers superior moisture-proof and dust-proof capabilities, saving labor and materials while delivering excellent packaging results. With adjustable features and online coiling capabilities, it meets diverse industrial needs and enhances operational efficiency.

Key Features:

Moisture-Proof & Dust-Proof: Protects products in various environments.

High Packaging Efficiency: Delivers consistent and superior results.

Adjustable Tension & Coverage: Customizable for different requirements.

Wide Wrapping Range: Suitable for annular items like pipes, hoses, tires, and metal belts.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The corrugated hose packing machine streamlines the process of wrapping corrugated hoses, providing durable and secure packaging. It’s suitable for multiple hose sizes and types, enhancing protection during transit, reducing manual labor, and increasing efficiency, making it an essential tool for industrial packaging operations.

The FPCA Series Hose Packaging Machine is specifically designed for various hose coils and other annular objects. It offers high-efficiency packaging with aesthetically pleasing results, effectively saving labor and material costs. The packaged products not only provide multiple layers of protection—such as moisture-proof, dust-proof, and corrosion resistance—but also effectively prevent accidental damage during transportation and storage.

FHOPE Packaging Machine Series

The FHOPE Packaging Machine Series is the ideal choice for your production packaging, storage, and transportation needs, as well as for enhancing brand quality and image.

It not only meets your standard requirements but can also be customized based on specific needs.

Features:

PLC and HMI with automatic material quantity calculation function (optional): Enables intelligent management.

Special design for easy manual loading and unloading: Improves operational efficiency.

Slow stop, soft start, and automatic reset functions: Ensure stability and safety during the packaging process.

Manual and automatic operation modes: Convenient and adaptable for different usage scenarios.

Adjustable ring speed: Accommodates different packaging speed requirements.

Overlap rate adjustment: Ensures the packaging is both aesthetically pleasing and secure.

Foot pedal soft start option: Provides diverse starting methods.

Motor-driven protection: Ensures safe equipment operation.

Easy-to-adjust support rollers: Prevents hose shaking during packaging and ensures packaging quality.

Horizontal hose packaging: Suitable for various hose sizes.

Easy loading and unloading of packaging materials: Simplifies the operation process.

Designed for different coil sizes: Meets diverse packaging needs.

Special design for easy manual loading and unloading: Enhances production efficiency.

Adjustable packaging tension via a special mechanical device: Ensures tightness and consistency in packaging.

Safety features such as guardrails, soft start, and stop: Ensure operator safety.

Compatible with a wide range of packaging materials: Serves the packaging needs of various industries.

Tension device ensures stable packaging quality.

Note: We can provide custom designs based on your specifications to meet your unique needs and expectations.

| Technical parameter | |

| Model | FPCA-100 |

| Power supply | 380v 50Hz 3Phase |

| Total power | About 1.2kw |

| OD | 250-400mm |

| ID | >250mm |

| Width | 100-200mm |

| Weight | 8-50kg |

| Wrapping speed | 20-35S/pc |

| Packing material | LLDPE/PE/PVC |

| Packing material size | ID50mm;OD80-100mm;Width70mm |

| Overlap rate | 10%-90% |

| Max ring speed | About 100r/min |

| Roller speed | About 3-5m/min |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635