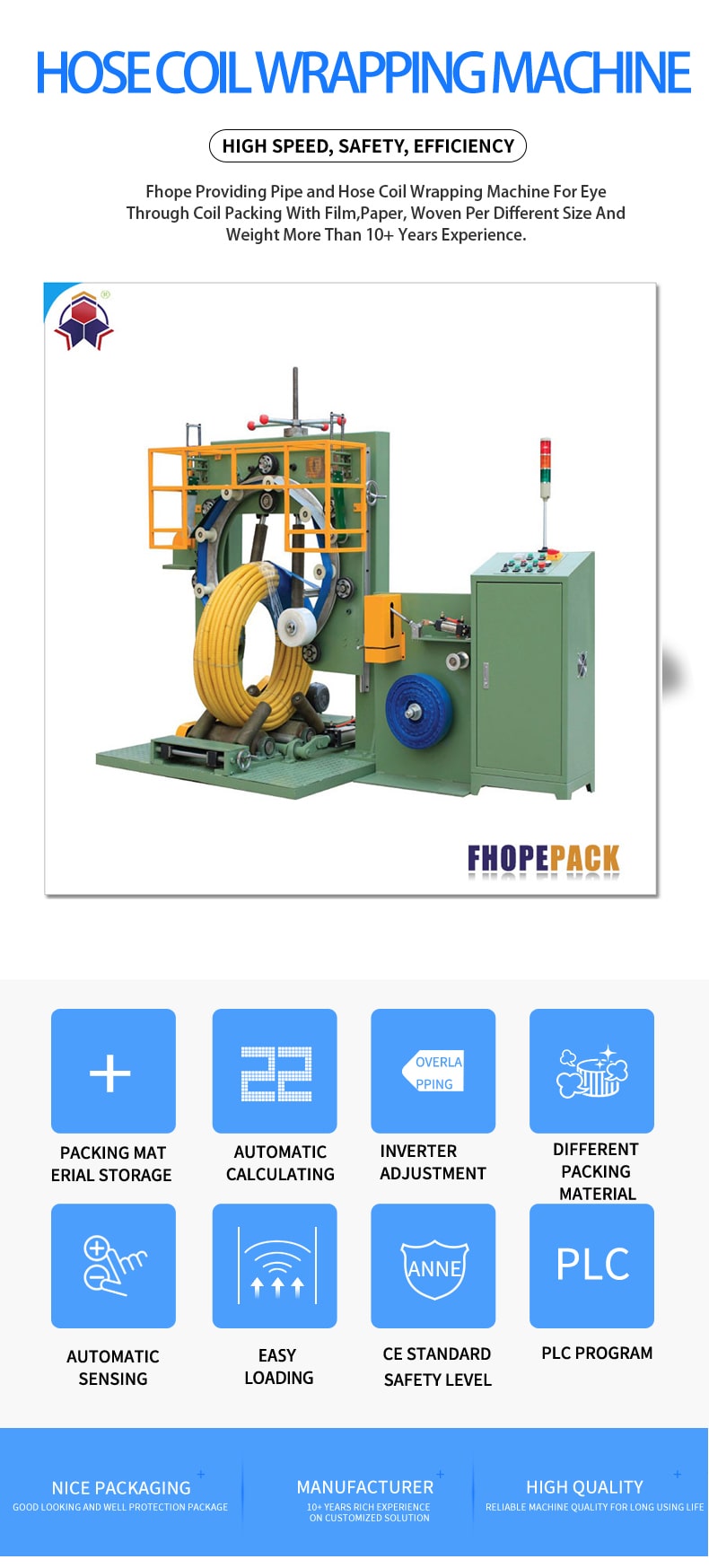

Hose Coil wrapping machinery FPH-400

The FPH-400 is a semi-automatic and automatic hose winding packaging machine, tailored for various coiled materials like plastic pipes, rubber hoses, and tires. Designed by Fhope, it ensures efficiency, safety, and enhanced product integrity during transportation, delivering a professional, polished appearance.

Key Features:

Versatile Applications: Supports packaging for a wide range of products, including ring-shaped objects.

Flexible Operation: Offers manual and automatic modes with adjustable rotating ring and roller speeds.

Customizable Packaging: Adjustable overlap rates and compatibility with multiple packaging materials, including multi-layer wrapping.

Enhanced Safety: Equipped with safety barriers, soft start/stop for the rotating ring, and adjustable tension for secure operation.

Special Features

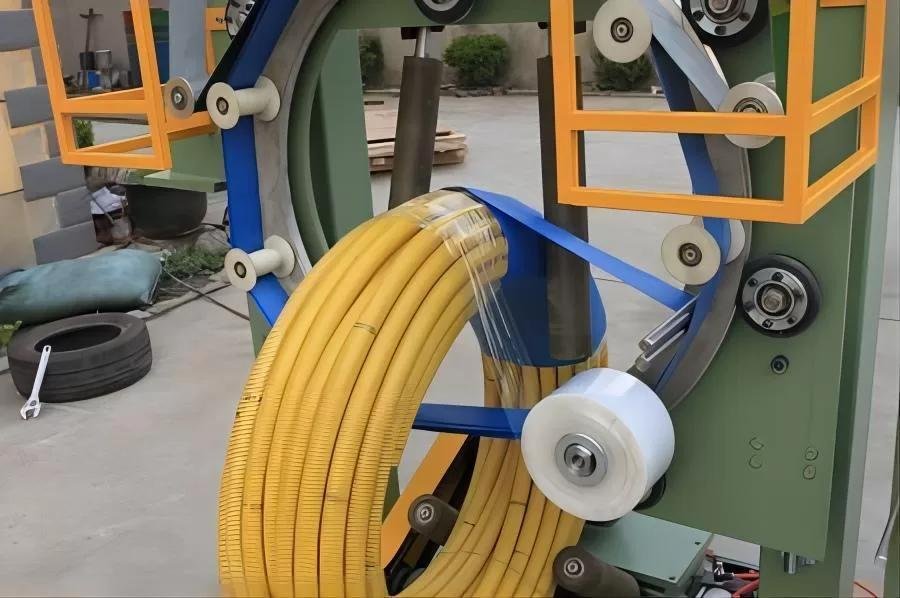

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The FPH-400 Hose Coil Wrapping Machine offers streamlined packaging for hose coils, improving efficiency and safeguarding products during transportation. With automated wrapping capabilities, it minimizes manual effort and reduces packaging material waste, delivering a cost-effective and reliable solution tailored for high-demand industrial applications.

FPH-400 Hose Winding Machine features advanced design and versatile functionality, making it capable of flexibly packaging various types of pipes. The machine not only enhances packaging efficiency but also ensures the safety and integrity of the product during transportation. Additionally, the packaged product has a neat and aesthetically pleasing appearance. It is an excellent assistant for customers seeking semi-automatic or automatic packaging solutions for various coiled materials.

FPH Series Hose Winding Packaging Machine, custom-designed by Fhope for industries such as rubber hoses and metallurgy.

This machine is widely applicable for the outer packaging of various ring-shaped objects, including plastic pipes, rubber hoses, and tires. It offers ease of access, simple operation, flexible adjustments, and high safety standards.

Additionally, it provides effective protection against rust, corrosion, dust, damage, and aging, improving the sealing quality, enhancing the appearance, and facilitating storage and transportation.

Features:

Versatile packaging applications: Suitable for a wide range of products without limitations.

Automatic reset of the rotating ring: Simplifies operation by automatically resetting after each winding.

Manual and automatic modes: Allows switching between manual and automatic operation modes.

Adjustable speed: The speed of the rotating ring and support rollers can be adjusted via a frequency converter.

Adjustable overlap rate: Adaptable to various packaging needs with an adjustable overlap rate.

Supports multiple packaging materials: Can use various outer packaging materials and allows for multi-layer wrapping simultaneously.

Safety features: Includes safety barriers, with soft start and stop for the rotating ring to improve operational safety.

Guide rollers: Effectively keep materials in optimal condition during the packaging process.

Adjustable tension: Tension can be adjusted based on packaging requirements.

Fast packaging speed: Packaging speed ranges from 20 to 35 seconds per package.

Note: The machine can be designed and customized according to customer specifications and requirements.

| Technical parameter | |

| Model | FPH-400 |

| Power supply | 380v 50Hz 3Phase |

| Total power | 1.5kw |

| OD | 800-1200mm |

| ID | 200-400mm |

| Width | 100-400mm |

| Weight | 5-100kg |

| Packing material | 20-35S/pc |

| Packing material | LLDPE/PE/PVC |

| Packing material size | ID 50mm;OD80-100mm;Width 70mm |

| Overlap rate | 10%-90% |

| Max ring speed | 10-90r/min |

| Roller speed | About 3-5m/min |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635