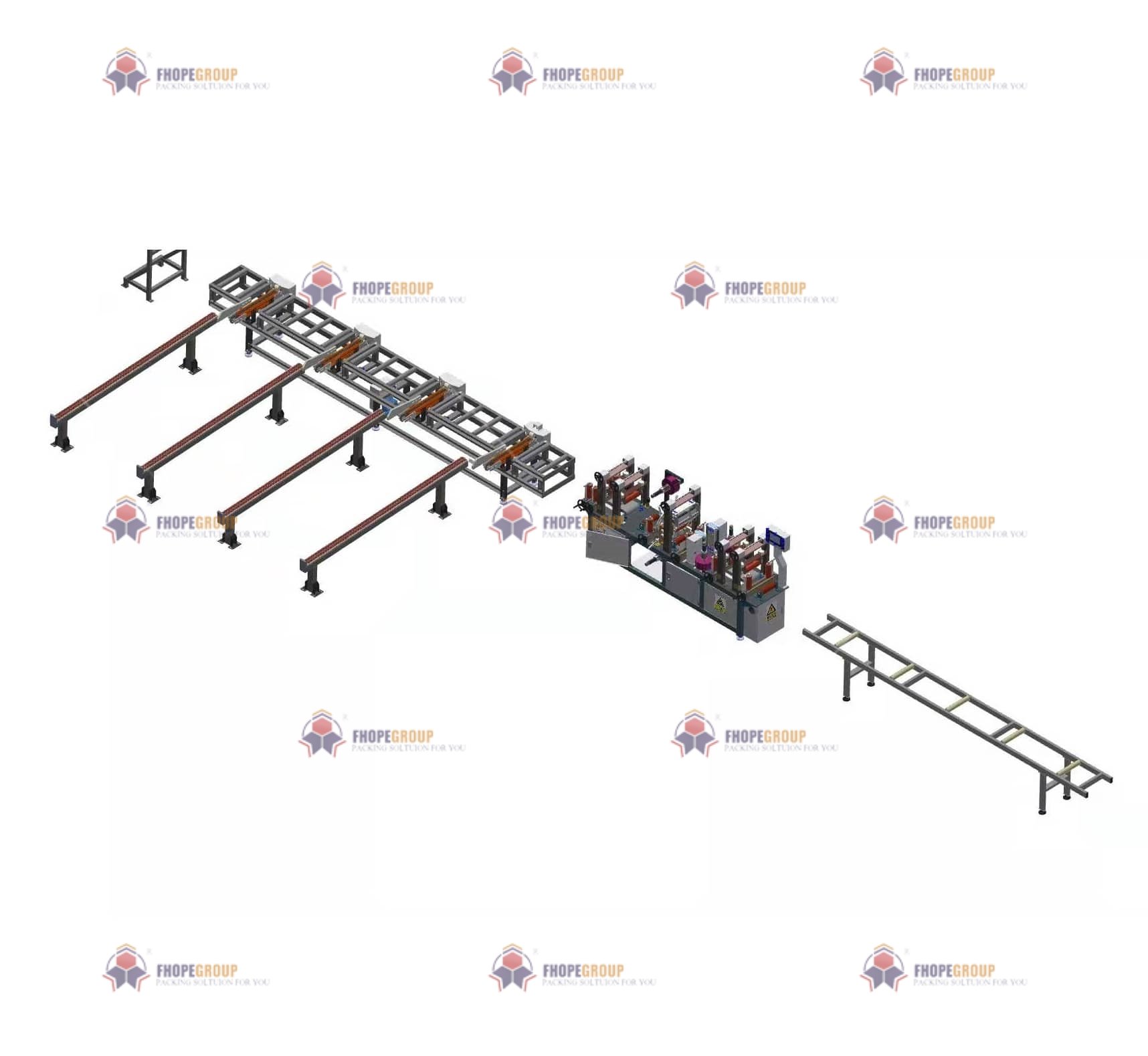

Horizontal orbital stretch wrapper with wooden feeding

The Automatic Horizontal Stretch Wrapper Machine is an advanced packaging solution designed for long and straight products like profiles, bars, and sheets. With intelligent automation and high-speed operation, it ensures secure and professional packaging while streamlining processes and reducing costs.

Key Features:

Comprehensive Packaging: Handles bundling, wrapping, and stacking seamlessly.

High-Speed Wrapping: Rotating wrapping ring with constant tension control ensures precision.

Intelligent Automation: Includes material detection, automatic cutting, and adjustable wrapping parameters.

Operator-Friendly: Minimal personnel needed; user-friendly controls simplify operation and maintenance.

Customizable Design: Supports quick material replacement and integrates into existing production lines.

Special Features

Related video

The Horizontal Orbital Stretch Wrapper with Wooden Feeding is designed for efficient wrapping of long, irregular items with added support from a wooden feeding system. Ideal for materials like rods, pipes, and panels, it ensures stable handling and precise wrapping. With adjustable settings and durable construction, it enhances packaging protection and operational efficiency.

Automatic Horizontal Stretch Wrapper Machine

Overview

The Automatic Horizontal Stretch Wrapper Machine is a highly specialized packaging solution for long and straight products, including profiles, bars, sheets, and similar items. Featuring advanced components such as a film covering device, sealer, timber feeding system, and wrapping machinery, this machine ensures packages are well-protected, sealed, and visually tidy.

Designed for seamless integration, it can connect to your existing production line, becoming an essential part of modern manufacturing and packaging processes. Its versatility and efficiency make it a popular choice across industries.

Key Features

1. Comprehensive Packaging Process

Handles bundling, packing, and stacking in one streamlined process.

Provides complete protection and professional appearance for packaged items.

2. Advanced Material Handling

Compact Steel Frame: Sturdy and space-efficient design ensures durability and operational efficiency.

Automatic Rollers: Adjust to different bundle dimensions without stopping the machine, ensuring a continuous workflow.

3. High-Speed Wrapping

The wrapping ring rotates to apply film, supported by a mandrel with a specially designed clutch to maintain constant tension throughout the wrapping process.

4. Intelligent Automation

Electronic Inverter Control: Regulates the speed of the machine for precise and consistent wrapping.

Automatic Detection System: Senses when wrapping material runs out or tears, halting the machine and alerting the operator.

Start-Stop Mode: Includes a blade that automatically cuts the wrapping material at the end of each cycle.

5. Flexible and Customizable

Strapping times and wrapping parameters can be adjusted to meet specific packaging requirements.

Supports quick and easy replacement of wrapping material in less than one minute.

6. Operator-Friendly Design

Requires minimal operator intervention with only two personnel needed for infeeding aluminum profiles.

User-friendly controls simplify operation and maintenance.

Specifications

| Parameter | Details |

|---|---|

| Object | Aluminum profiles |

| Bundle Dimensions | Min: 300x300x6500mm, Max: 500x500x6500mm |

| Air Supply | 6-8 bar |

| Operator Requirement | 2 people (for infeeding) |

Benefits

1. Enhanced Efficiency

Reduces packaging time by automating bundling, wrapping, and stacking.

Continuous operation minimizes downtime, even when handling bundles of varying sizes.

2. Superior Product Protection

Packages are tightly wrapped and sealed, safeguarding them from environmental factors during transportation and storage.

3. Cost and Time Savings

Automated processes reduce labor requirements and material wastage.

Quick replacement of wrapping materials ensures minimal downtime.

4. Seamless Integration

Easily integrates into existing production lines, enhancing workflow and productivity.

Applications

This machine is ideal for industries requiring packaging of:

Aluminum Profiles

Metal Bars

Sheets and Panels

Long and Straight Objects

Contact us to learn more and customize your machine!

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635