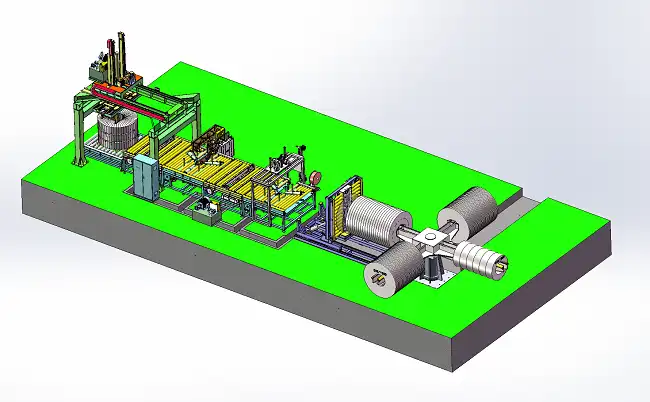

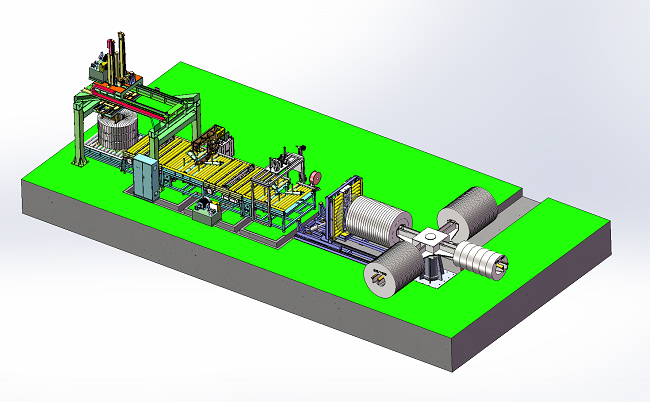

Copper coil packing line

Copper tube coil packing machines are specialized equipment designed to wrap and secure copper tubing coils with protective materials such as paper, woven fabric, PE, or stretch film. These machines are widely used in the manufacturing and distribution sectors to ensure that copper tubing remains safe from damage and contamination during transportation and storage.

Key Features:

Horizontal Design: Facilitates easy feeding of copper tubing coils into the wrapping system.

Versatile Packaging Options: Supports a variety of protective materials to suit different packaging needs.

Adjustable Wrapping Settings: Inverter-adjustable wrapping ring and tension control provide flexibility for different coil sizes and packaging requirements.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The copper coil packing line is a specialized system for efficiently packaging copper coils. It offers automated processes like wrapping, strapping, and sealing to ensure secure and damage-free handling. Designed for industrial demands, it improves productivity, minimizes material waste, and provides reliable protection during storage or transportation.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635