Copper Tube Coil

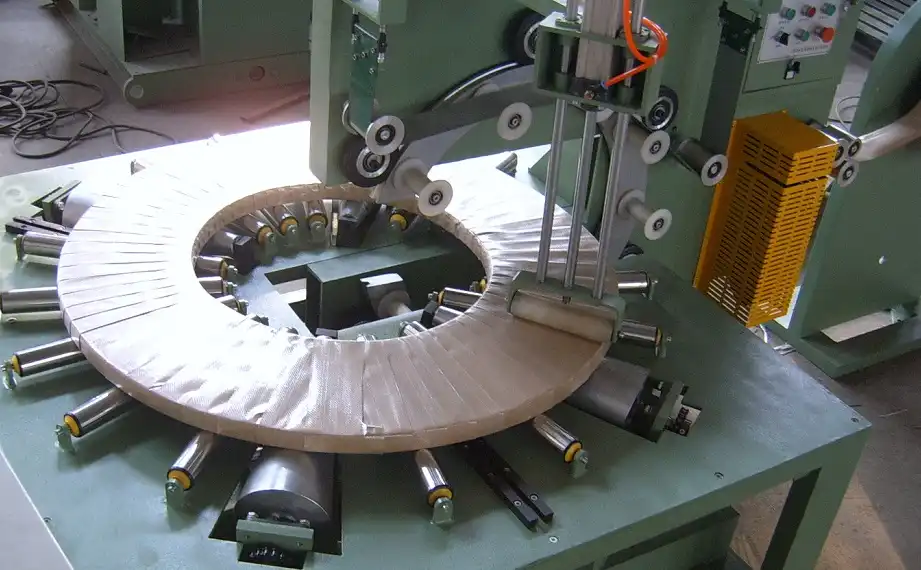

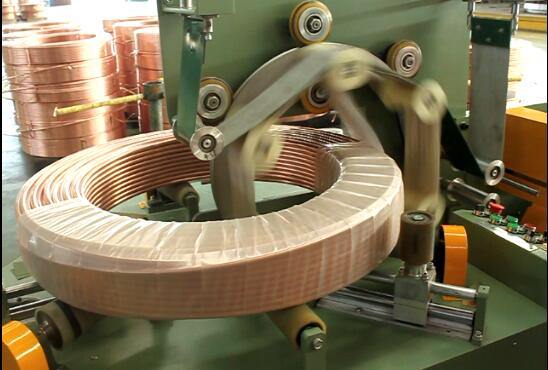

Copper tube coil packing machines are specialized equipment designed to wrap and secure copper tubing coils with protective materials such as paper, woven fabric, PE, or stretch film. These machines are widely used in the manufacturing and distribution sectors to ensure that copper tubing remains safe from damage and contamination during transportation and storage.

Key Features:

Horizontal Design: Facilitates easy feeding of copper tubing coils into the wrapping system.

Versatile Packaging Options: Supports a variety of protective materials to suit different packaging needs.

Adjustable Wrapping Settings: Inverter-adjustable wrapping ring and tension control provide flexibility for different coil sizes and packaging requirements.

Secure Wrapping: Wrapped coils are secured with tape or fasteners to ensure stability during handling.

Automatic Conveyor System: Streamlines operations by moving packaged coils to the stacking area efficiently.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

Copper tube coils are essential for heat transfer and fluid systems, offering superior thermal conductivity and resistance to corrosion. Widely used in HVAC, refrigeration, and industrial applications, they ensure efficiency and durability. Available in various specifications, these coils are designed for reliable performance in demanding environments, meeting diverse operational needs.

Copper tube coil packing machines are used to wrap and secure copper tubing coils with protective material, such as paper, woven fabric, polyethylene (PE), or stretch film. These machines are typically horizontal in design and operate by feeding the copper tubing coil into the machine, where it is wrapped with the protective material using a series of rollers or other wrapping mechanisms. The wrapped coil is then secured with tape or other fastening methods to keep it in place during transportation and storage. Copper tube coil packing machines are commonly used in the manufacturing and distribution of copper tubing products, and can help protect the tubing from damage and contamination during shipping and handling.

These features indicate that the copper tube coil packing machine is designed to be user-friendly and easy to operate, even for those with limited technical knowledge. The inverter-adjustable wrapping ring and adjustable wrapping tension allow for flexibility in packaging different size products, and the ability to choose different packing materials allows for versatility in the types of protection provided to the copper tubing. The machine also has an automatic conveyor system for moving packaged coils to the stacking area, and includes a trouble indicator to alert the operator of any issues that may arise during the packaging process. The machine's strong structure and easy maintenance make it a reliable choice for copper tube packaging, and the use of PU on contact surfaces helps to protect the product during the wrapping process.

Technical Parameters of Packaging Line

| Parameter | Specification |

|---|---|

| Object weight | 50-300kg |

| Package width | 10-300mm |

| Package OD | 600-1200mm |

| Package ID | 500-800mm |

| OD-ID | <500mm |

| Roller Speed | 2-4m/min |

| Wrapping speed | 25-45sec/pcs |

| Rotating speed | 20-110r/min |

| Overlap scope | 20%-90% |

| Power voltage | 380v/50/60Hz/3ph |

| Air supply | 5-8kgf/m² |

| Packing material | Woven belt | Paper ID:50mm OD:150-400mm Width:90mm |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635