Cable strapping

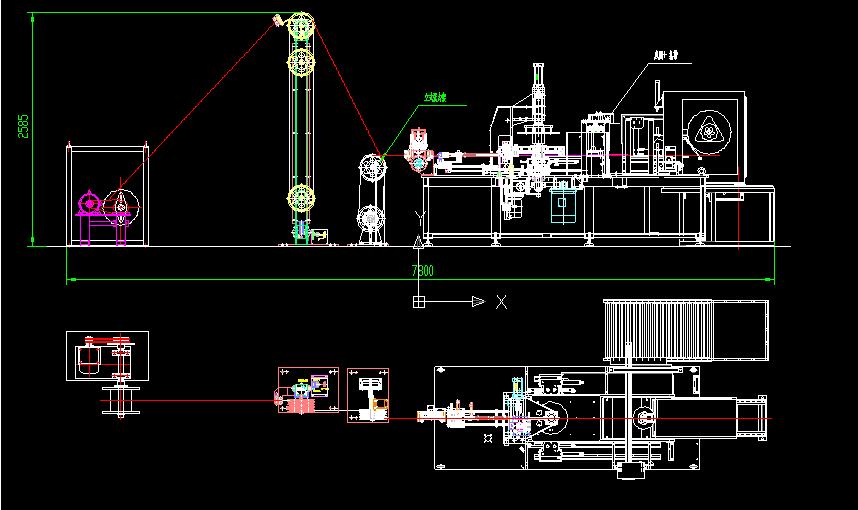

The automatic cable coil strapping machine is an advanced solution for enhancing the cable production and packaging process. With its ability to strap coiled cables using PP straps and integrate seamlessly with production lines, it ensures efficiency, precision, and reliability.

Key Features

Strapping Versatility: Equipped with a PP strap head for heat-welded strapping with adjustable tension.

Integrated Workflow: Can be connected to a payoff machine or integrated into a production line for seamless operation.

Strap Options: Available in configurations with 1, 2, or 4 straps to suit specific production needs.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

Cable strapping provides a strong, flexible solution for organizing and securing cables and wires. Made from durable materials, it is designed to resist wear and tear in various environments. Suitable for both professional and personal use, cable strapping helps maintain a neat workspace and prevents tangling, enhancing overall efficiency.

Automatic Cable Coil Strapping Machine: Precision and Efficiency for Cable Production

The Automatic Cable Coil Strapping Machine is a highly advanced piece of equipment designed to streamline the cable production and packaging process. By automating cable coiling, cutting, and strapping, it ensures precision, consistency, and enhanced productivity for various industrial applications.

Key Features of the Automatic Cable Coil Strapping Machine

Integration with Production Lines

Can be connected to a production line or a payoff machine for seamless operations.

Automatically produces coiled cables with PP straps, ensuring secure packaging.

Adjustable Strap Tension and Heat Welding

Uses a PP strap head to join strap ends via heat welding with adjustable tension.

Provides strong, durable straps tailored to specific production needs.

Flexible Strapping Options

Available in configurations with 1, 2, or 4 straps, accommodating different requirements.

Ensures secure handling and transport of coiled cables.

Automatic Coil Handling

Features a coil holder that picks up and moves coiled cables to the next station automatically.

Reduces manual labor and improves workflow efficiency.

Offline Packaging Capability

Measures, cuts, coils, and straps cables offline, offering flexibility for standalone use.

Advanced Technology and Compliance

Built using FHOPE cable coiling technology, renowned for reliability and innovation.

Complies with CE guidelines, ensuring safety and industrial usability.

Reliable and Easy to Maintain

Features a robust strapping platform designed for high strapping success rates.

Incorporates technological innovations for easy maintenance and safety.

Advantages of Using an Automatic Cable Coil Strapping Machine

Enhanced Efficiency

Automates multiple steps in the cable production process, reducing manual labor and downtime.

High Precision and Accuracy

Automatically measures and cuts cables to desired lengths, ensuring consistent results.

Customizable for Production Needs

Offers flexibility in strapping configurations and adjustable tension for various applications.

Improved Safety Standards

Complies with CE industrial safety guidelines, protecting operators and ensuring secure operations.

Cost-Effective

Reduces labor costs and increases throughput, leading to a better return on investment.

Versatility

Suitable for diverse industrial applications, including cable manufacturing and electrical equipment production.

Applications

This machine is ideal for industries requiring efficient and precise cable coiling and strapping, such as:

Wire and Cable Manufacturing

Electrical and Telecommunications Industries

Industrial Cable Packaging Solutions

By integrating an Automatic Cable Coil Strapping Machine into your production process, you can significantly improve the efficiency, accuracy, and reliability of your operations while maintaining high safety and quality standards.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635