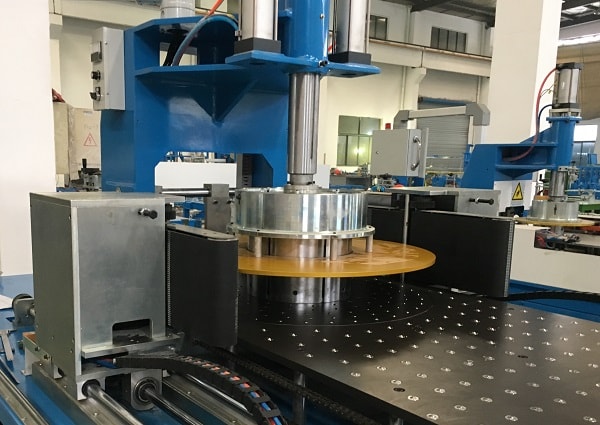

Automatic cable winding machine

The automatic cable coiling and wrapping machine is designed to streamline and automate the cable packaging process. It ensures precision, reliability, and user convenience through advanced technology and intuitive controls.

Advantages

Enhanced Accuracy: Automated systems ensure precise coiling and reliable operation.

Operational Efficiency: Minimizes manual intervention, saving time and reducing labor costs.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The automatic cable winding machine offers an efficient solution for winding cables with minimal manual intervention. Its advanced design ensures consistent quality and precise winding, catering to different cable sizes and types. Equipped with intuitive controls, this machine enhances production efficiency, making it an essential tool for modern cable manufacturing operations.

Automatic Cable Coiling and Wrapping Machine: Streamlined Efficiency and Precision

The Automatic Cable Coiling and Wrapping Machine is a highly advanced solution designed to streamline the cable packaging process. By automating cable length calculation, coiling, cutting, and optional wrapping or strapping, this machine significantly enhances efficiency, accuracy, and consistency.

Key Features of the Automatic Cable Coiling and Wrapping Machine

Fully Automated Coiling Process

Handles cable feeding, coiling, dispensing, length checking, and cutting automatically.

Ensures precision and consistency, saving time and reducing manual errors.

User-Friendly Control System

Features a touch screen interface with an intuitive program accessible in English.

Allows easy adjustments and monitoring of operations.

Displays error notifications on the screen and activates an alarm light for quick troubleshooting.

Advanced Detection and Tension Control

Uses a sensor and servo system to automatically detect cable position for accurate coiling.

Equipped with a magnet power tensioner to maintain consistent coiling tension, ensuring high-quality results.

Online and Offline Operations

Online Mode: Connects to the cable production line for seamless packing during manufacturing.

Offline Mode: Operates as a standalone unit for post-production coiling and wrapping.

Available in two modes:

Expandability for Full Automation

Can be paired with a wrapping or strapping machine to create a fully automated packaging line, further enhancing productivity.

Advantages of the Automatic Cable Coiling and Wrapping Machine

Time and Labor Savings

Automates complex processes, reducing the need for manual intervention.

Increases production speed while maintaining precision.

Improved Accuracy and Consistency

Ensures accurate cable length measurement and consistent coil sizes with minimal variation.

Enhanced User Experience

Intuitive touch screen controls make the machine accessible to operators of all skill levels.

Immediate error detection and alarm notifications minimize downtime.

Flexibility in Operations

Offers both online and offline functionality, making it adaptable to various production setups.

Expandable with additional wrapping or strapping units for complete automation.

Reliability and Durability

High-quality components and advanced systems ensure long-term, reliable performance.

Applications

This machine is an excellent choice for industries requiring high-speed, precise cable coiling and wrapping, such as:

Cable and Wire Production

Electrical Manufacturing

Telecommunications

Its ability to seamlessly integrate with production lines and deliver consistent results makes it an essential tool for modern cable packaging operations.

| Specification | Details |

|---|---|

| Coil Size ID | 140-200 mm |

| Coil Size OD | 240-460 mm |

| Coil Height | 60-100 mm |

| Weight | 50 kg (max) |

| Single Cable Diameter | 3-15 mm |

| Coiling Speed | 2-2.5 coil/min |

| Air Supply | 6 bar |

| Coil Feed Style Mode | Hold coil type |

| Meter Counter | 0.01 m - 100 m |

| Power Voltage | AC 380V, 50Hz, 3 phase |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635