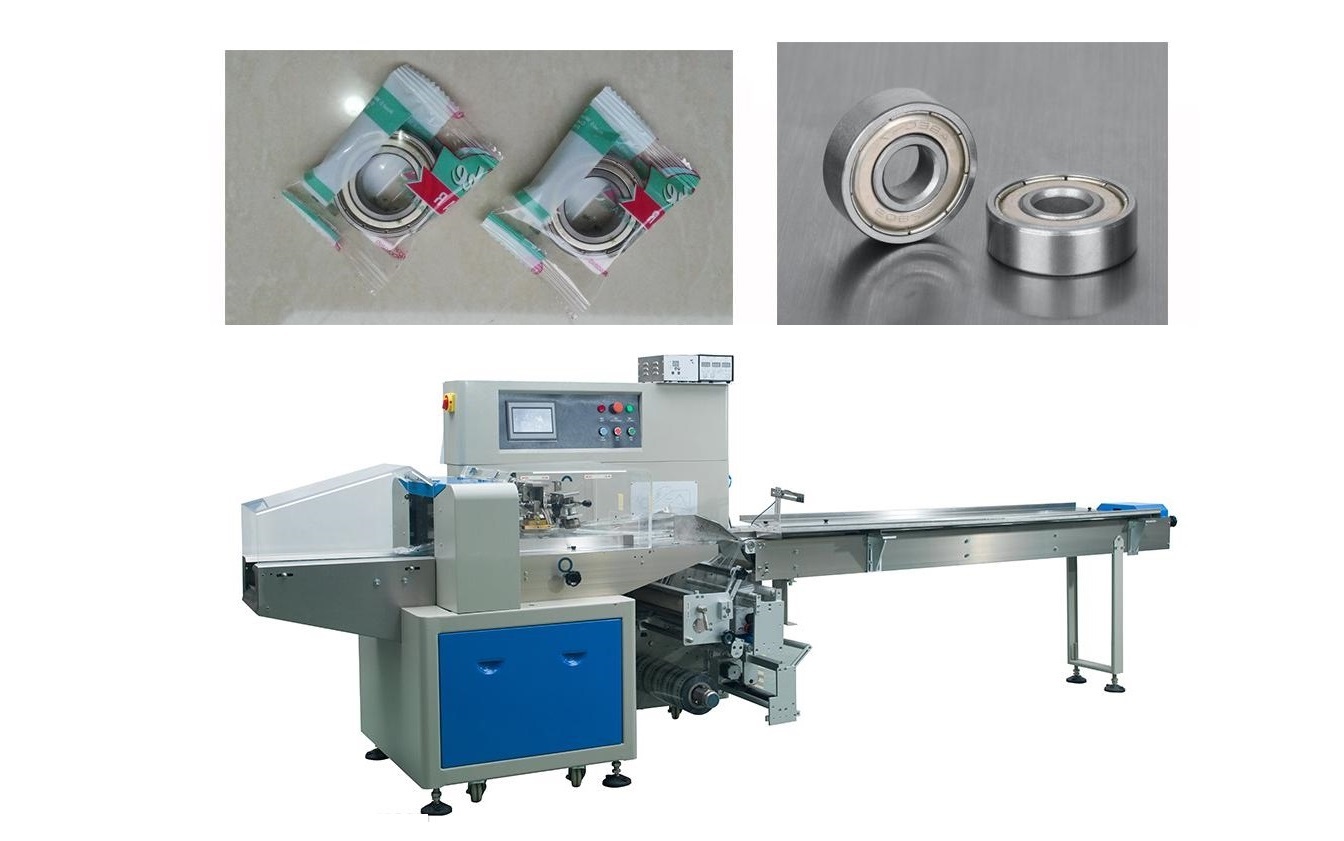

Bearing bag packing machine

The horizontal bearing bag packing machine is a state-of-the-art solution for efficiently packaging small bearings into sealed bags. Designed with advanced technology and compliance with CE safety guidelines, it ensures high-speed, precise, and reliable operation.

Key Features

Advanced Automation:

PLC Program Control: Automated processes controlled with precision using a servo system.

Servo Motor Technology: Ensures accurate operation and efficient performance.

Flexible Operation:

Offers both manual and automatic modes to suit different operational needs.

Adjustable action time to accommodate various packing purposes.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The bearing bag packing machine provides an efficient solution for sealing bearings in protective bags. It ensures secure and contamination-free packaging, safeguarding bearings during storage and transportation. With its automated operation and precise performance, the machine enhances efficiency and consistency, making it ideal for various industrial needs.

Horizontal Bearing Bag Packing Machine: Efficient and Reliable Packaging for Small Bearings

The Horizontal Bearing Bag Packing Machine is an advanced, automated solution designed to efficiently package small bearings into sealed bags. With a high-speed capability of up to 60 pieces per minute, this machine combines precision, flexibility, and safety, making it a valuable asset for industries requiring consistent and reliable packaging.

Key Features of the Horizontal Bearing Bag Packing Machine

Automated PLC Program Control

Operated by a Programmable Logic Controller (PLC) with a servo system, ensuring precise and efficient packaging processes.

Automatic Bag Sealing

Includes an integrated system for automatic bag sealing, providing consistent and secure packaging.

Adjustable Action Timing

Flexible settings for action time adjustment, catering to different packaging requirements.

Servo Motor for Precision

Ensures precise operation and accurate execution of packaging tasks, reducing errors and material waste.

Dual Operation Modes

Offers both manual and automatic modes, allowing flexibility to adapt to various production scenarios.

Adjustable Conveyor Speed

Equipped with inverters for conveyor speed adjustment to optimize workflow efficiency.

Precise Temperature Control

Maintains consistent temperature for bag sealing, ensuring durable and professional-quality seals.

Advanced Positioning and Safety Features

Sensors and mechanical limiting stoppers guarantee accurate bearing positioning during packaging.

Motor overcurrent protection safeguards equipment and ensures operational safety.

Automatic Film Feeding System

Streamlines the process by automatically feeding packaging film, reducing manual intervention.

Benefits of the Horizontal Bearing Bag Packing Machine

High Efficiency

Capable of sealing up to 60 bearings per minute, significantly increasing production speed.

Enhanced Packaging Consistency

Servo-driven precision and automated controls ensure uniform packaging quality across batches.

Labor and Cost Savings

Automates multiple steps of the packaging process, reducing labor requirements and material waste.

Safety and Compliance

Built to CE safety guidelines, protecting operators and maintaining compliance with industrial standards.

Flexibility and Customization

Adjustable settings and dual operation modes make it adaptable for different bearing sizes and packaging needs.

Applications

The Horizontal Bearing Bag Packing Machine is ideal for:

Automotive Component Manufacturing

Industrial Machinery Production

Bearing Distribution and Supply Chains

Why Choose the Horizontal Bearing Bag Packing Machine?

This machine delivers a combination of speed, precision, and reliability, enabling businesses to enhance their packaging efficiency while maintaining high-quality standards. By investing in this solution, you can:

Optimize operational efficiency with advanced automation.

Ensure consistent product protection during handling and transport.

Reduce costs through labor savings and minimal material waste.

The Horizontal Bearing Bag Packing Machine is an essential tool for industries aiming to achieve high-speed, professional packaging for small bearings.

| Specification | Details |

|---|---|

| Packaging Material | OPP, OPP/CPP, KOP/CPP, ALU-FILM |

| Material Dimensions | OD: 100-200 mm, ID: 75 mm |

| Material Thickness | 20-40 microns |

| Bearing Size | OD: 20-130 mm |

| Bearing Width | 10-80 mm |

| Bagging Speed | Approximately 10-120 pcs/min |

| Air Supply | 5-7 bar |

| Power Supply | 380V, 3 Phase, 50/60 Hz |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635