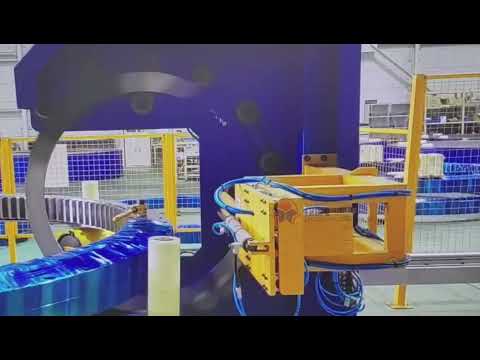

Big size bearing packing machine

FHOPE’s advanced packaging solution for large bearings combines high efficiency, safety, and versatility to meet the demands of industries such as wind power and heavy machinery manufacturing. This solution ensures robust protection for bearings during shipping and handling while automating key processes to improve operational efficiency.

Automatic Packing Material Feeder

Integrated Cutter: Automatically clamps and cuts packaging material to improve wrapping precision and reduce errors.

Labor Savings: Eliminates the need for manual tying and cutting, streamlining the process.

Consistent Results: Ensures even and accurate material application for better product protection.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The big-size bearing packing machine is a specialized solution for packaging large bearings with precision and care. It offers secure wrapping to protect against environmental factors and damage during transport. Equipped with automated features, it ensures efficiency, consistency, and reliability, making it perfect for heavy industrial operations.

FHOPE Packaging Solution for Large Bearings: High Efficiency and Comprehensive Protection

FHOPE’s packaging solution for large bearings offers a high-efficiency, automated approach to wrapping and protecting bearings during shipping and handling. By integrating advanced features such as multi-layer wrapping and automated material feeding, this solution ensures consistent, high-quality packaging while reducing manual labor and operational costs.

Key Features of the FHOPE Packaging Solution

Multi-Layer Wrapping with Oil Application

Capable of applying three layers of packaging material (e.g., stretch film, woven fabric, or paper) in a single pass.

Includes an option to apply protective oil to bearings during the wrapping process for enhanced protection.

Adjustable for Different Sizes

Fully adjustable design accommodates a wide range of bearing sizes, making it versatile for various industries.

Automatic Packing Material Feeder

Features a cutter that can clamp and cut packaging material automatically.

Eliminates the need for manual tying and cutting, improving efficiency and reducing errors.

High Efficiency and Consistency

Streamlines the wrapping process, enabling quick and consistent packaging of large quantities of bearings.

Reduces handling time, ensuring operational speed and reliability.

Safety and Reliability

Designed with safety features such as guardrails, soft starts/stops, and precision clamping mechanisms to protect both operators and equipment.

Durable components ensure long-term reliability, even in high-demand production environments.

Benefits of FHOPE’s Packaging Solution

Enhanced Product Protection

Multi-layer wrapping and oil application shield bearings from moisture, dust, and mechanical damage during transport and storage.

Improved Operational Efficiency

Automates the packaging process, significantly reducing manual labor and increasing throughput.

Precision and Accuracy

Automated feeding and cutting mechanisms ensure consistent wrapping quality and minimize material waste.

Cost Savings

Reduces labor costs and operational delays associated with manual packaging.

Optimizes material usage to prevent overuse and waste.

Adaptability to Industry Needs

Wind Power: Protects bearings used in wind turbine assemblies.

Heavy Machinery Manufacturing: Ensures durability during transport for large, high-load bearings.

Ideal for industries requiring reliable packaging solutions for large bearings, including:

Applications

This packaging solution is particularly suited for:

Wind Power Equipment Manufacturing

Heavy Machinery Production

Industrial Bearing Manufacturing and Distribution

Why Choose FHOPE for Large Bearing Packaging?

FHOPE delivers a packaging solution that combines automation, efficiency, and precision, making it a valuable investment for businesses in heavy industries. By choosing FHOPE, you gain:

Reliable protection for large bearings during shipping and handling.

Operational efficiency through advanced automation.

Customizable solutions to meet specific production demands.

This solution ensures that your large bearings are protected, your packaging processes are streamlined, and your overall operational costs are minimized.

| Specification | Details |

|---|---|

| Machine Model | FPCA-6000 |

| Object Weight | 500-12000 kg |

| Package Width | 150-600 mm |

| Package Outer Diameter (OD) | 2900-5000 mm |

| Package Inner Diameter (ID) | 2500-4200 mm |

| OD-ID Constraint | Less than 950 mm |

| Operator | One person |

| Wrapping Speed | Approximately 60-110 sec/coil (with three layers one-time packing option) |

| Roller Speed | 2-4 m/min |

| Rotating Speed | 10%-90% |

| Overlap Scope | Customized available |

| Power Output | Approximately 4.5 kW |

| Power Voltage | 200 V / 60 Hz / 3 phase |

| Packing Material | VCI Film |

| VCI Film Dimensions | ID: 50 mm, OD: 100-300 mm, Width: 200 mm |

| Stretch Film Dimensions | ID: 50 mm, OD: 100-300 mm, Width: 300 mm |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635