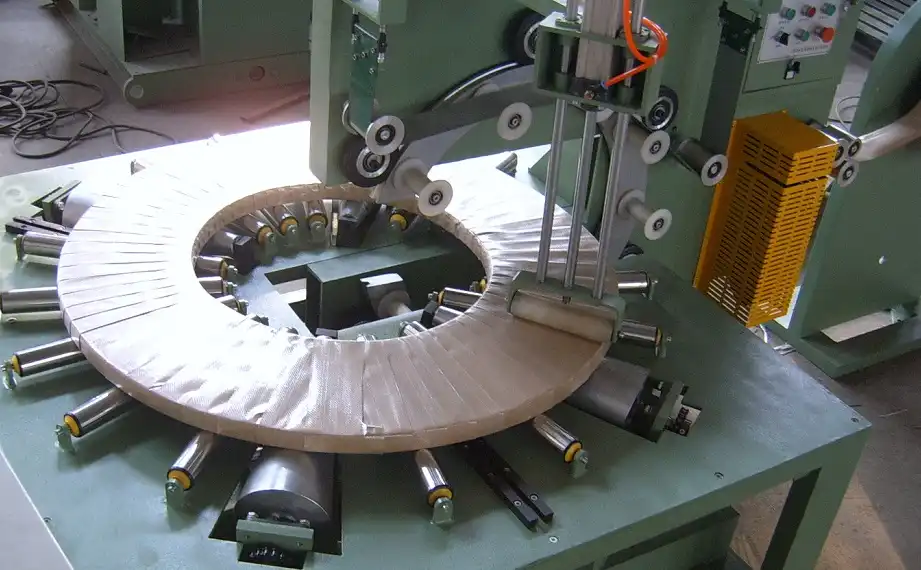

Bearing wrapping machine

The bearing wrapping and packing machine is a specialized solution for packaging large bearings and axletrees, offering enhanced protection, efficiency, and cost savings. Its automation capabilities and advanced controls make it ideal for industries requiring consistent and reliable packaging solutions.

Advantages

Enhanced Protection: Ensures bearings are securely packaged, reducing the risk of damage during shipping and handling.

High Efficiency: Automates the packaging process to save labor and time while improving consistency.

Cost Savings: Increases packing speed and reduces manual labor, lowering overall packaging costs.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

The bearing wrapping machine is designed to provide efficient and protective packaging for bearings. It ensures a secure wrap, safeguarding bearings from external elements like dust and moisture. With its automated operation and user-friendly design, it enhances productivity while maintaining high-quality packaging standards for industrial applications.

Bearing Wrapping and Packing Machine: Economical and Efficient Packaging Solution

The Bearing Wrapping and Packing Machine is a specialized, automated solution designed to efficiently package large bearings and axletrees. By improving packaging quality and automating the process, this machine reduces labor costs, minimizes errors, and enhances the protection of bearings during shipping and handling.

Key Features of the Bearing Wrapping and Packing Machine

Seamless Integration with Production Lines

Designed to connect directly to a bearing production line, enabling full automation of the wrapping and packing process.

Advanced Control System

Incorporates a PLC (Programmable Logic Controller) and HMI (Human-Machine Interface) for smooth, efficient operation.

Easy-to-use controls for monitoring and adjusting parameters.

Precision and Accuracy

Features sensors and automatic positioning to ensure accurate alignment of bearings during wrapping.

Reduces the risk of errors, improving overall packaging quality.

Flexible Operation Modes

Supports both manual and automatic modes, offering flexibility to meet varying production requirements.

Adjustable Speed Control

Uses a frequency converter to fine-tune the packaging speed, allowing customization based on specific needs.

Enhanced Error Detection

Equipped with an indicator light and fault display to quickly identify and address issues, minimizing downtime.

Benefits of Using the Bearing Wrapping and Packing Machine

Improved Packaging Quality

Ensures bearings are securely wrapped and protected during shipping, reducing the risk of damage.

Enhances the overall performance and reliability of the packaged products.

Increased Efficiency

High-speed wrapping reduces labor and packaging time, lowering operational costs.

Automates repetitive tasks, allowing workers to focus on higher-value activities.

Flexibility and Control

Dual operation modes and adjustable speed provide users with greater control over the packaging process.

Error Minimization

Advanced sensors and positioning systems reduce the likelihood of mistakes, ensuring consistent results.

Cost-Effective Solution

Optimizes labor and material usage, making it an economical choice for the bearing industry.

Ideal Applications

This machine is well-suited for industries that require reliable and efficient packaging solutions for large bearings and axletrees, such as:

Automotive Manufacturing

Aerospace Industry

Industrial Machinery Production

Why Choose the Bearing Wrapping and Packing Machine?

With its robust automation, precision, and flexibility, the Bearing Wrapping and Packing Machine offers a reliable and economical solution for businesses. By investing in this machine, you can:

Improve packaging quality and product protection.

Enhance operational efficiency and reduce costs.

Achieve consistent, high-quality packaging results for your bearings and axletrees.

This machine is a valuable addition to any production line seeking to streamline processes, minimize errors, and optimize costs.

| Specification | Details |

|---|---|

| Machine Model | FPB-300 |

| Voltage (V/Hz) | AC 380/50 (or your requirement) |

| Power (KW) | 2.5 |

| Bearing ID (mm) | 300-900 |

| Bearing OD (mm) | 600-1200 |

| Bearing Width (mm) | 20-300 |

| Bearing Weight (Kg) | 10-500 |

| Packing Material | Goffered paper/PE/Stretch film/Knit belt/PVC |

| Ring Speed (r/min) | 30-70 |

| Wrapping Speed | 40-50 sec/pce |

| Overlapping Rate | 20-80% |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635