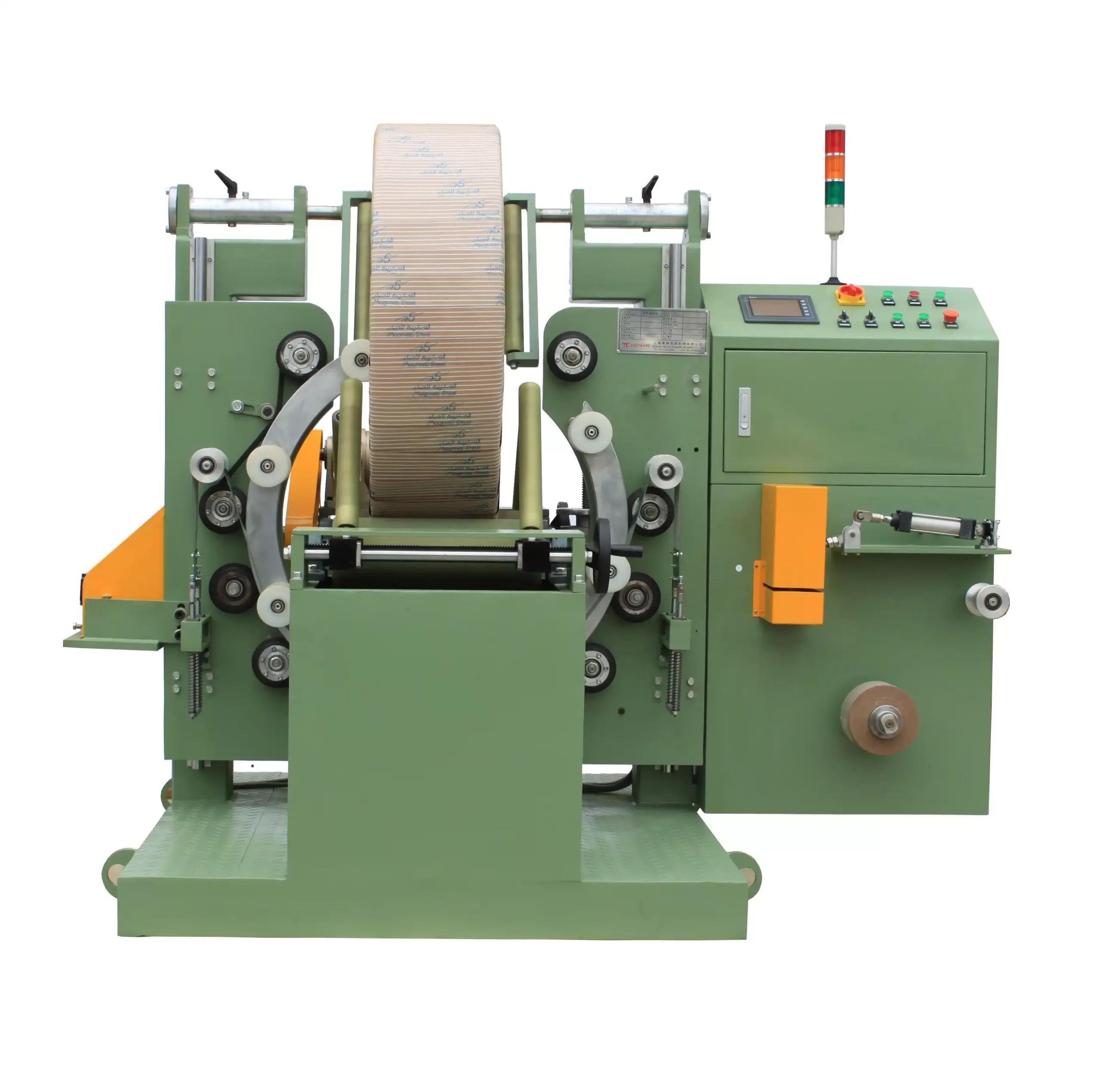

Bearing packing machine

A bearing packing machine is designed to efficiently package bearings and axletrees with precision and consistency. Its advanced automation and customization capabilities make it ideal for industries such as automotive, aerospace, and manufacturing, where reliable and efficient packaging is critical.

Key Features

Automated Material Handling: Includes conveyor systems for feeding and transferring bearings and axletrees, reducing manual intervention.

PLC-Controlled Operation: Ensures automated processes with enhanced speed, precision, and consistency.

ID-Based Positioning: Uses identification systems to position bearings accurately for wrapping and labeling.

Flexible Operation Modes: Offers both manual and automatic modes to adapt to specific operational needs.

Special Features

Efficient Wrapping Mechanism

Provides uniform and secure wrapping for coils of various sizes, ensuring optimal protection during storage and transportation.

Adjustable Tension Control

Allows precise adjustment of wrapping tension to accommodate different materials and prevent damage to coils.

High-Speed Operation

Processes multiple coils rapidly, increasing throughput and minimizing downtime in large-scale production environments.

Related video

A bearing packing machine streamlines the packaging of bearings by utilizing automated systems for accuracy and speed. It effectively handles various sizes and types, providing secure packaging that protects against damage during transit. This machine is essential for manufacturing operations aiming to improve efficiency and reduce packaging costs while maintaining quality.

Bearing Packing Machine: Precision and Efficiency for Industrial Packaging

A Bearing Packing Machine is a specialized solution designed to package bearings and axletrees with precision and efficiency. With automated features and advanced controls, this machine ensures consistent, high-quality packaging for industries such as automotive, aerospace, and manufacturing, where reliability and efficiency are paramount.

Key Components of the Bearing Packing Machine

Material Handling System

Equipped with conveyor belts or automated handling systems to feed bearings and axletrees into the machine seamlessly.

Packaging System

Encloses bearings in protective materials to safeguard against environmental factors and damage.

Additional Features

Label printers or code scanners for tracking and identification.

Supports advanced labeling for streamlined logistics and inventory management.

Advanced Control Features

PLC-Controlled Automation

Incorporates a Programmable Logic Controller (PLC) for fully automated operation.

Reduces manual intervention, improving speed, consistency, and accuracy in packaging.

Automatic Positioning System

Uses bearing ID for precise positioning during the wrapping process.

Ensures accurate and consistent packaging and labeling for each item.

Motorized Loading and Unloading

Features automatic motor conveyors to load and unload bearings, minimizing manual labor.

Dual Operation Modes

Offers both manual and automatic modes to suit varying operational requirements.

Safety and Maintenance

Alarm system to promptly detect and notify operators of issues, reducing downtime.

Soft start and stop functionality reduces wear and tear on components, extending machine life.

Wrapping Ring Reset System

Ensures the wrapping process remains consistent and precise for a high-quality final product.

Advantages of the Bearing Packing Machine

Enhanced Efficiency

Automates critical tasks such as positioning, wrapping, and labeling, improving productivity.

Consistency and Accuracy

Advanced positioning and control systems ensure uniform packaging quality for all bearings.

Labor Savings

Reduces the need for manual intervention, freeing workers for higher-value tasks.

Durability and Longevity

Features like soft stops and starts protect components, leading to long-term reliability.

Improved Traceability

Integrated label printers and scanners facilitate tracking and identification throughout the supply chain.

Customizability

Adjustable settings to meet specific operational requirements, making it versatile for different industries.

Applications

The Bearing Packing Machine is ideal for:

Automotive Manufacturing: Ensures bearings are securely packaged for assembly lines and distribution.

Aerospace Industry: Provides precision packaging for high-performance bearings.

General Manufacturing: Offers reliable packaging solutions for various industrial applications.

Why Choose a Bearing Packing Machine?

Investing in a bearing packing machine can enhance your production line by:

Boosting efficiency and reducing costs.

Ensuring consistent product quality.

Providing a scalable solution for growing operational demands.

With its combination of advanced automation, reliability, and flexibility, the bearing packing machine is a vital asset for businesses seeking to optimize their packaging operations.

| Specification | Details |

|---|---|

| Machine Model | FPB-200 |

| Voltage (V/Hz) | AC 380/50 (or your requirement) |

| Power (KW) | 1.5 |

| Bearing ID (mm) | 300-600 |

| Bearing OD (mm) | 700-1000 |

| Bearing Width (mm) | 20-200 |

| Bearing Weight (Kg) | 20-200 |

| Packing Material | Goffered paper/PE/Stretch film/Knit belt/PVC |

| Wrapping Speed | 35-45 sec/pcs |

| Overlapping Rate | 20-80% |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635