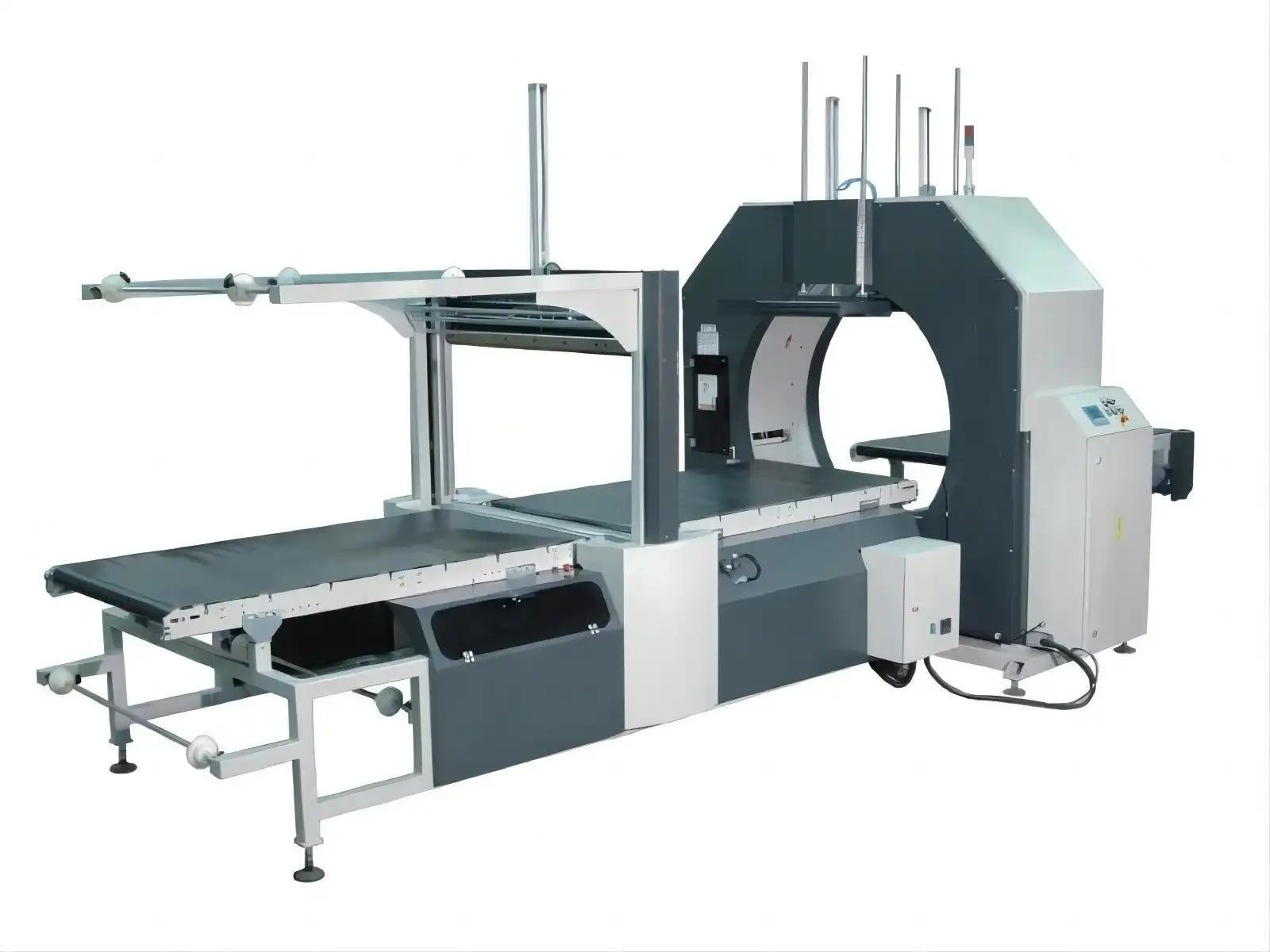

E500 horizontal wrapping machine&stretch wrapper

The Bubble Film Covering and Film Wrapping Orbital Horizontal Stretch Wrapper is an advanced packaging solution designed to provide full coverage for long-shaped products like wooden boards, sofas, panels, and fragile items. Combining bubble film covering with stretch film wrapping, it ensures superior product protection, efficient automation, and professional packaging results.

Key Features:

Dual Wrapping Technology: Bubble film covering and stretch film wrapping for comprehensive protection.

Automated Operation: Automatic feeding, cutting, and wrapping minimize manual intervention.

Customizable Settings: Adjustable tension, overlap (10%-90%), and speed for diverse packaging needs.

Safety Design: CE-standard safety features, including shielded components and soft press devices.

HMI & PLC Control: User-friendly touchscreen interface for precise operation and monitoring.

Special Features

Related video

The E500 Horizontal Wrapping Machine & Stretch Wrapper is engineered for high-performance packaging of long, bulky items like pipes, rods, and panels. Combining efficient stretch wrapping with adjustable speed and tension settings, it ensures secure and consistent wrapping. Built for durability and ease of use, the E500 enhances packaging efficiency and product protection in industrial application

Bubble Film Covering and Film Wrapping Orbital Horizontal Stretch Wrapper

Overview

This advanced orbital horizontal stretch wrapper combines bubble film covering and film wrapping technologies to provide full coverage packaging for long-shaped products such as wooden boards, sofas, and panels. Designed for durability and efficiency, the machine ensures superior product protection with bubble film sealing and precise wrapping, ideal for industrial and commercial packaging needs.

Equipped with a user-friendly HMI interface and a programmable PLC system, the wrapper simplifies operation and offers full control over packaging parameters, speed, and material tension. It features automated material feeding, cutting, and sealing mechanisms, eliminating the need for manual intervention and ensuring uninterrupted packaging workflows.

Key Features

1. Horizontal Stretch Wrapping Station

Ring-Type Wrapper: Provides 360-degree wrapping for comprehensive coverage.

Automated Film Application: Automatically applies film for efficient packaging.

CE-Standard Safety Design: Mechanical components are designed for operator safety.

Adjustable Friction and Speed: Friction and ring speed are adjustable using inverters for optimal performance.

Soft Start and Jog Functions: Ensures smooth operation and reduced mechanical stress.

Short Package Handling: Allows easy passage of shorter packages through the machine.

Material Tension Adjustment: Supports various packaging materials with adjustable tension.

Bubble Film Sealing: Sealer prevents film sticking during cutting, ensuring clean and secure seals.

Touchscreen Control: Allows real-time adjustment of wrapping parameters for customization.

Protection Shields: Safeguards all moving parts for safe operation.

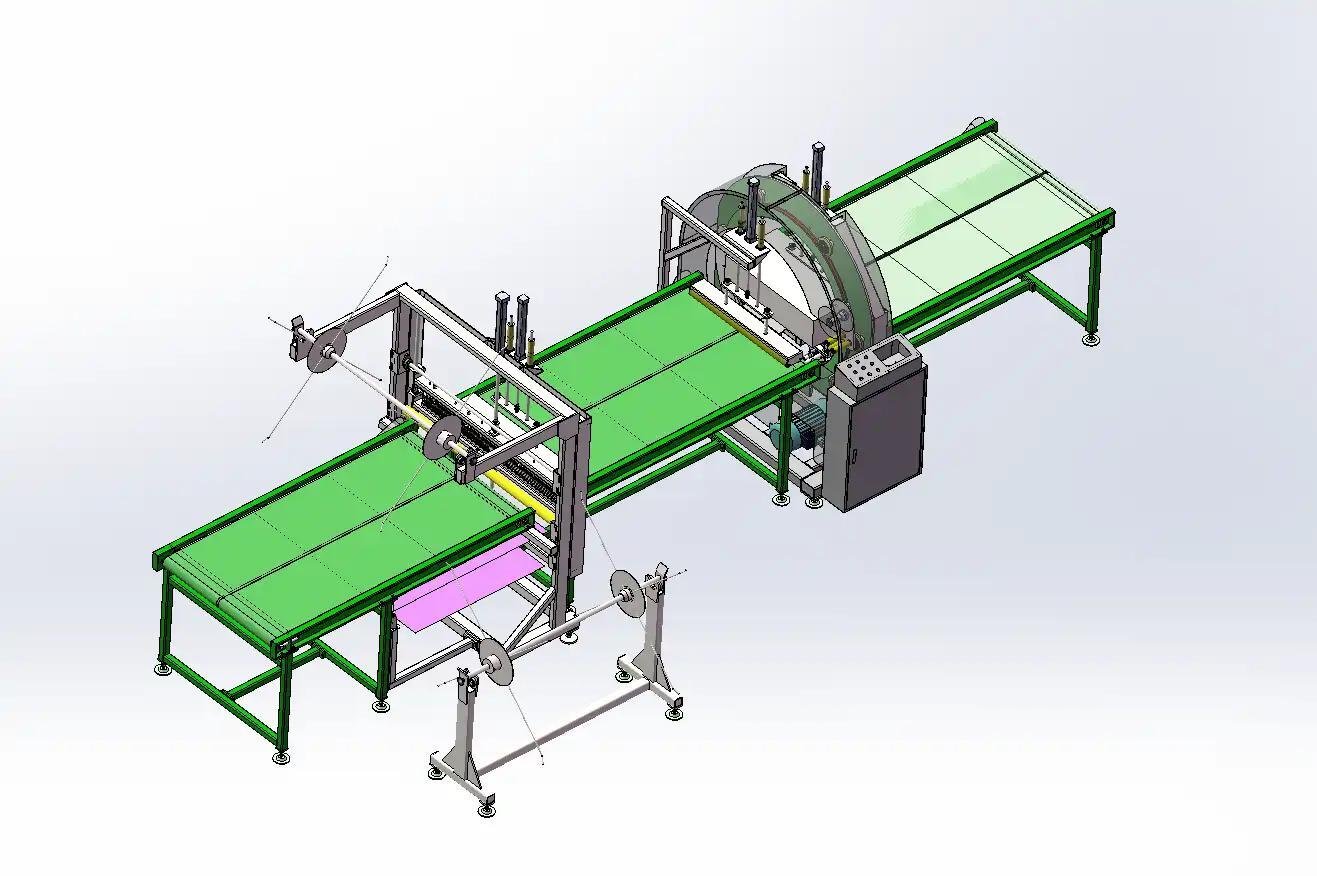

2. Conveyor System

Surface Options: Soft conveyor surfaces in PU, PVC, or rubber to protect product finishes.

Automatic Infeed and Outfeed: Streamlines material handling for continuous operation.

Load Capacity: Customizable for different product weights and sizes.

Speed Control: Adjustable conveyor speed using inverters for synchronized wrapping and movement.

Sensor Detection: Detects objects for precise infeed, wrapping, and outfeed actions.

Shielded Drive System: Protects all moving parts for enhanced safety.

3. Automatic Mechanical Hand

Material Feeding and Cutting: Automatically feeds and cuts film for uninterrupted wrapping.

Automatic Clamping: Prepares materials for the next wrapping cycle.

Sensor and PLC Control: Ensures precision and adaptability for various product sizes and packaging needs.

Bubble Film Sealer: Seals and cuts bubble film without sticking for smooth operation.

4. PLC & HMI Control System

Automatic Wrapping: PLC program customizes wrapping based on specific goals.

HMI Interface: Simplifies parameter adjustments for ring speed, conveyor speed, head delays, and end delays.

Photocell Sensor Positioning: Ensures precise positioning with adjustable detection settings.

Automatic Alarms: Alerts operators to issues with troubleshooting guidance displayed on the touchscreen.

Reinforced Wrapping: Adjustable for additional security at product ends via touchscreen.

Separate Control Panel: Simplifies operation and maintenance, ensuring ease of use.

5. Press Down Device

Soft Pressing Down: Adjustable force for protecting fragile surfaces, such as glass or bubble film.

Side Protective Devices: Manually adjustable to prevent product movement during wrapping.

Top Press Device: Soft material ensures surface protection for delicate products.

Infeed and Outlet Pressing: Dual press devices secure products during entry and exit.

Applications

The machine is ideal for packaging:

Wooden Boards

Sofas and Furniture

Panels and Sheets

Doors and Windows

Fragile Items (e.g., glass panels)

Installation Components

Two Conveyor Sets: Ensures smooth product transportation.

Bubble Film Covering Machine: Applies bubble film to products for enhanced protection.

Wrapping Station: Core component for automated film application and wrapping.

Benefits

1. Superior Protection

Provides full coverage wrapping with bubble film and stretch film for complete protection against environmental damage.

2. Efficiency and Automation

Automated feeding, cutting, and wrapping minimize manual labor and increase production speeds.

3. Customization

Adjustable tension, overlap, and speed settings ensure optimal results for various product sizes and shapes.

4. Enhanced Safety

CE-standard safety features, including shielded components and soft pressing devices, protect operators and products.

5. Cost-Effective Operations

Reduces material waste and labor costs while maintaining consistent packaging quality.

Technical Data

| Parameter | Specification |

|---|---|

| Object Size | Length: >1500mm, Bundle OD: 200-500, Weight: 50-500kg |

| Infeed Conveyor | 2000mm L × 700mm W |

| Outfeed Conveyor | 2000mm L × 700mm W |

| Material Width | 150~300mm |

| Material | LLDPE Stretch Film / Paper / Woven Width: 150-300mm, OD: 100-250mm, ID: 50mm (Let me know, if you need another size) |

| Air Supply | 5~8kgf/cm² |

| Conveyor Speed | 3~12m/min |

| Ring Speed | App. 10-60r/min |

| Machine Size | App. L5200 x W1600 x H1800mm |

| Power Output | About 4.5kw |

| Power Voltage | AC 380v, 50Hz, 3Phase |

| Control Power Voltage | ADC24 |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635