E300 Horizontal stretch wrapping machine

The FHOPE Fully Automatic Horizontal Wrapping Machine E300 is an advanced solution for efficiently packaging long, straight items such as pipes, doors, panels, and aluminum profiles. With seamless automation, precise control, and customizable settings, it ensures secure and professional packaging while significantly reducing labor and material costs.

Key Features:

Rotating Ring System: Adjustable speed, tension, and overlap for optimal wrapping.

Automated Operation: PLC-controlled with robotic arms for film feeding and cutting.

Conveyor System: Motor-driven, adjustable speed, and surface-protecting design.

Fault Detection: Alerts and troubleshooting display for minimal downtime.

Versatility: Supports multiple materials and customizable settings for various product sizes.

Special Features

Related video

The E300 Horizontal Stretch Wrapping Machine is built for heavy-duty industrial applications, providing secure and efficient wrapping for long items like pipes, rods, and panels. With advanced features such as adjustable tension, variable speed control, and a robust design, it ensures consistent wrapping performance, enhanced product protection, and optimized packaging efficiency.

FHOPE Fully Automatic Horizontal Wrapping Machine E300 is specifically designed for the automated packaging of materials such as pipes, doors, flooring, and various aluminum profiles. It ensures a highly efficient and precise packaging process. After being wrapped by the machine, the finished products are not only neatly arranged but also tightly packed, with a clean and aesthetic appearance. Additionally, the machine is capable of seamlessly integrating with existing packaging production lines, enabling fully automated packaging workflows and significantly enhancing packaging efficiency.

E300 Fully Automatic Horizontal Wrapping Machine demonstrates extraordinary capabilities in the field of long, straight item packaging. Its wide range of applications covers diverse materials, from metal extrusions to wood products, from construction items to oil pipes, doors and windows, as well as thin panels, textiles, and insulation panels. With its precise control system and flexible adjustment mechanisms, the machine easily meets the packaging needs of products of various sizes, ensuring optimal results with every wrap. Additionally, the E300 is designed to enhance packaging efficiency by significantly reducing labor input through automation and effectively lowering packaging costs. It also supports a variety of packaging materials, offering businesses more choices and flexibility.

Wrapping Station:

Reinforced aluminum cast rotating ring: Ensures secure and durable packaging.

PU wheels: Enhance safety, stability, and reduce noise during operation.

Unique mainboard design: Provides a stronger structure and frame.

Adjustable friction: Between the drive wheel and rotating ring for precise control.

Variable ring speed: Adjustable via a frequency inverter.

Soft start/stop for the wrapping ring: Ensures smooth operation.

Auto-reset sensor for packaging position: Automatically returns to the starting position.

Adjustable material tension: For optimal wrapping tightness.

Versatile material rack: Compatible with a wide range of packaging materials.

Protective cover: Fully shields the machine's moving parts.

Overlap adjustment: Can be set between 10% and 90%.

Adjustable start/stop points: Packaging start and stop positions can be customized.

Ring speed control via touchscreen: Digital adjustment for precise operation.

Conveyor System:

Transition plates: Suitable for products longer than 600mm for smooth transportation.

PVC conveyor structure: Protects the surface of the product during transport.

Automatic infeed and outfeed lines: Streamlines the loading and unloading process.

Motor-driven conveyor belt: Ensures reliable transportation.

Adjustable conveyor speed: Controlled by a frequency inverter to match the packaging speed.

Material detection sensors: Detect the product position for accurate packaging.

PLC Control System:

Automated packaging process: The PLC system automatically adjusts based on packaging needs.

Photoelectric sensor positioning: Ensures precise and adjustable packaging positions.

Automatic fault detection and alarms: Indicator lights and touchscreen alerts notify the operator of issues, with detailed fault displays for easy troubleshooting.

Independent control panel: Simplifies operation and maintenance.

Touchscreen adjustments: Allows for easy control of ring speed and conveyor speed.

Automatic stop at packaging position: Adjustable through the touchscreen.

Touchscreen and button interface: Facilitates easy operation of machine functions.

Adjustable operation timings: Set operation times according to product requirements.

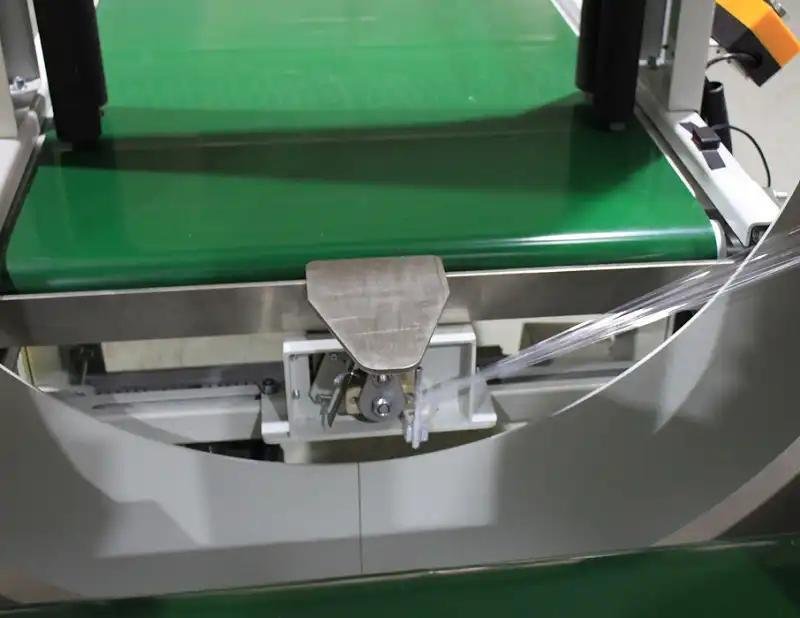

Automatic Robotic Arm:

Automatic film feeding and cutting: Ensures efficient film supply and cutting.

Automated film loading: Prepares the machine for the next packaging cycle.

Sensor and PLC control: Precision control over film feeding and cutting.

Adjustable operating parameters: Tailored to different packaging needs.

Unmanned operation: Fully automated, hands-free operation.

Multiple packaging modes: Supports different materials and packaging styles.

Pressing Device:

Side protection devices: Manually adjustable to prevent product movement during packaging.

Top pressing device: Soft material used for surface protection of the packaging product.

Two pressing devices: Located on the infeed and outfeed conveyors.

Time-adjustable protection device: Can be set for different packaging purposes.

Protective system: Suitable for different frame structures and non-flat surfaces.

Operating Instructions:

Place the product on the infeed conveyor.

Automatic product detection: The sensor detects the product and moves it to the wrapping position.

Start wrapping process: The rotating ring begins wrapping the product while the pressure roller secures it.

Reinforced wrapping at the product’s end: Ensures tight and secure packaging.

Packaging completes: The product is transferred to the outfeed conveyor.

Unload the packaged product: Remove the finished package from the outfeed conveyor.

Repeat cycle: The machine resets and prepares for the next product.

This comprehensive and efficient machine provides a powerful solution for industries packaging long, straight items, offering precise control, automation, and reduced labor costs.

Technical Parameters

| Parameter | Specification |

|---|---|

| Bundle OD | 100-300mm |

| Bundle Length | >1000mm |

| Weight | 15-100kg |

| In-Feeding Conveyor Length | 2000mm with motor |

| Out-Feeding Conveyor Length | 2000mm with motor |

| Speed | 6~12m/min |

| Ring Speed | 20-90r/min |

| Wrapping Speed | 5-15m/min |

| Power Output | About 2.5kw |

| Power Voltage | 380v, 3PH, 60Hz |

| Packing Material | Polyethylene Foil OD: 100-200mm, Width: 100-200mm, ID: 50mm |

Guarantee Values

| Guarantee Aspect | Details |

|---|---|

| Ring Speed | 20-90r/min |

| Wrapping Effect | Product surface is smooth and even |

| Working Hours of the Machine | Effective working hour per year: 7200h |

| Environmental Protection | Noise control of the equipment environment must meet national requirements for noise control. |

| Emission Standard | Emission of waste gas and waste water meets national requirements. |

Contact us to learn more and customize your machine.

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635