E1400 Horizontal stretch wrapping machine

The Orbital Ring Stretch Wrapper & Film Wrapping Machine is a versatile, efficient solution for packaging long, bundled, or delicate items such as trays, profiles, and fragile goods. Combining automation with sustainability, it enhances packaging speed, reduces labor costs, and ensures product protection.

Key Features:

Reinforced Aluminum Ring: Durable design with adjustable speed and friction for secure, consistent wrapping.

Automatic Material Handling: Film feeding, cutting, and tension adjustments streamline the wrapping process.

Advanced Conveyor System: Soft-touch conveyor surfaces protect products while ensuring smooth transport.

Customizable Settings: Adjustable overlap (10%-90%), tension, and wrapping parameters for tailored packaging needs.

Safety Design: CE-standard shielding and soft start/stop features ensure operator and product safety.

Special Features

Related video

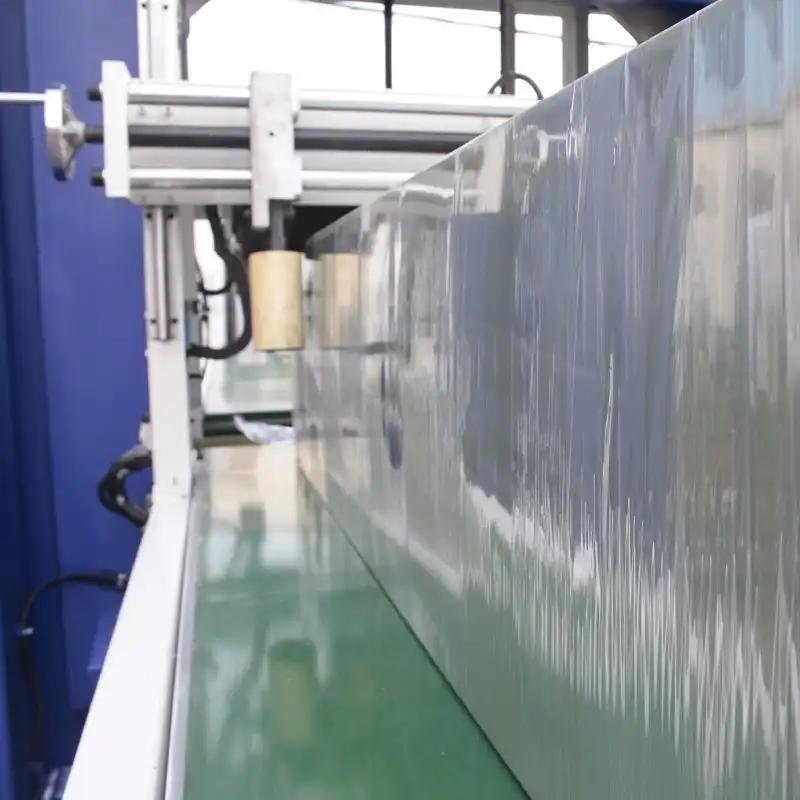

The Big-Size Orbital Stretch Wrapping Machine is specifically designed for wrapping large items such as doors and panels. With a robust rotating mechanism and adjustable settings, it ensures secure and uniform packaging for oversized products. Ideal for industrial applications, this machine enhances product protection and streamlines packaging processes for bulky items.

Automatic Horizontal Orbital Stretch Wrapping Machine

Overview

This Automatic Horizontal Orbital Stretch Wrapping Machine is engineered for packaging large-size products such as sheets, doors, and floorboards with widths up to 1400mm. Equipped with advanced tension control, it ensures that wrapped packages are well-sealed, tidy, and intact. Designed for both online and offline operations, the machine enhances packaging efficiency and offers cost savings, making it an ideal solution for modern production lines.

Key Features

1. Wrapping Station

Double-Ring & Double-Rubber Wheel Devices: Provides stability, safety, and energy-efficient operation.

Adjustable Friction: Customizable friction between driving wheels and the ring for precise control.

Inverter-Controlled Ring Speed: Adjustable speed ensures flexibility for various packaging requirements.

Soft Start and Stop: Protects the product and machine by minimizing mechanical stress.

Automatic Reset: Wrapping position resets automatically to prepare for the next package.

Tension Control: Adjustable packing material tension ensures optimal wrapping tightness.

Material Compatibility: Supports a variety of packaging materials with a versatile material frame.

Safety Features: Includes guardrails and fully enclosed moving parts for safe operation.

Adjustable Overlap: Customizable from 10%-90% to meet specific packaging needs.

2. Conveyor System

Versatile Conveyor Options: Available in PVC belt, roller, or chain configurations based on load requirements.

Product Surface Protection: Ensures tight film packing without damaging the product surface.

Automatic Infeed and Outfeed: Streamlines product handling for continuous packaging.

Motor-Driven Conveyor with Gearbox: Delivers reliable and smooth product transport.

Inverter-Controlled Speed: Adjustable conveyor speed for synchronized operation.

Object Detection Sensors: Detects products and triggers operation actions automatically.

3. Automatic Wrapping Protective Device

Soft Rollers: Protect product surfaces during wrapping.

Press Down Devices: Tailored to different load shapes and features for precise positioning.

Anti-Shaking Mechanisms: Prevents product movement during wrapping for consistent results.

Supportive Rollers: Fix packaging position securely.

Gap Handling: Pressing down devices ensure short loads pass smoothly through conveyor gaps.

Safety Shield Covers: Fully enclosed for safe operation and accident prevention.

4. PLC & HMI Control System

Automated Wrapping Process: The PLC system ensures the machine operates according to predefined packaging goals.

Photocell Sensors: Precisely sets the packing position and adjusts as needed.

Trouble Indicators: Alarms and touchscreen notifications simplify troubleshooting and maintenance.

Separate Control Panel: Simplifies operation and maintenance tasks.

User-Friendly Interface: HMI touchscreen allows intuitive operation and easy parameter adjustments.

5. Automatic Mechanical Hand

Automatic Film Feeding and Cutting: Clamper device feeds and cuts wrapping material seamlessly.

Adjustable Timing: Customizable action timing for efficient film release and application.

Sensor-Driven Operation: Controlled by sensors and PLC programming for precise cutting and clamping.

Simultaneous Actions: Clamping and cutting occur simultaneously for uninterrupted operation.

Benefits

1. Enhanced Efficiency

Automates the wrapping process, reducing labor costs and increasing throughput.

Infeed and outfeed systems streamline product handling, enabling continuous operation.

2. Superior Product Protection

Tight, consistent wrapping ensures products are protected from environmental factors and handling wear.

Adjustable tension and overlap settings accommodate different package types.

3. Safety and Ease of Use

Fully enclosed moving parts and guardrails ensure operator safety.

Intuitive HMI interface and automated processes make the machine easy to operate and maintain.

4. Cost-Effective Operations

Minimizes material waste through precise wrapping and tension control.

Flexible for both online and offline operations, reducing the need for multiple machines.

Applications

This machine is ideal for packaging:

Sheets and Panels

Doors and Floorboards

Wide and Flat Items

Heavy and Large-Sized Packages

Technical Parameters

| Parameter | Specification |

|---|---|

| Object Size | Length: 1000-3000mm, Width: 300-1400mm, Height: 50-1000mm |

| In-Feeding Conveyor Length | 2000mm |

| Out-Feeding Conveyor Length | 2000mm |

| Speed | 4~15m/min |

| Ring Speed | 10-60r/min |

| Power Output | About 4.5kw |

| Power Voltage | AC 380v, 60Hz, 3Phase |

| Material | Paper / LLDPE Stretch Film / PE Film / PVC Width: 300/500mm, OD: 200-300mm, ID: 50mm |

Request an Instant Quote for Your Projects!

We'd like to work with you

If you’ve got concerns and specific requirements, please speak to one of our Industry Experts. He/she will support you from planning to shipping.

- +8613951501635

- info@fhopepack.com

- +8613951501635